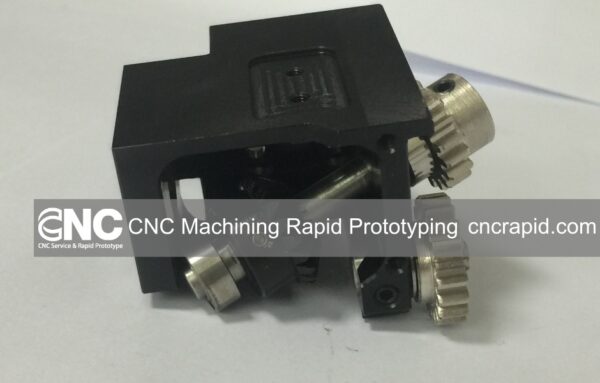

At CNC Rapid, we specialize in precision CNC gear machining, delivering high-quality custom gears to meet the diverse needs of our clients. Using advanced high-speed gear hobbing machines, we are capable of machining a wide range of gear types, from small, intricate gears to larger industrial components. Our expertise in machining gears from various materials, combined with the precision of CNC technology, ensures that every gear we produce meets the highest standards of accuracy and performance.

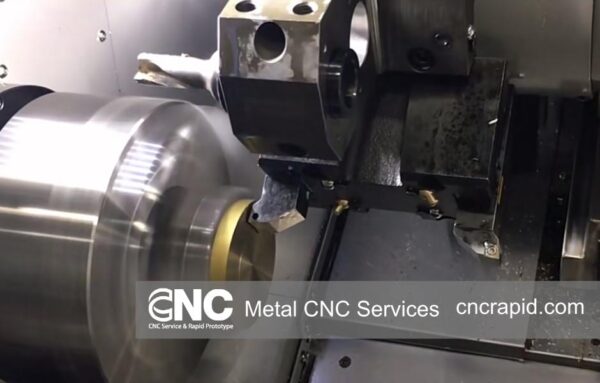

Advanced High-Speed Gear Hobbing Technology

Our CNC high-speed gear hobbing machines allow us to machine gears with unparalleled precision. Gear hobbing is a highly efficient process used to cut gears by using a hob to progressively shape the gear teeth. The CNC technology we employ ensures that every cut is made with absolute accuracy, delivering consistent and reliable results across all gear types.

The high-speed capabilities of our gear hobbing machines allow us to increase production efficiency while maintaining exceptional quality. This combination of speed and precision is particularly valuable for clients who need gears in a timely manner without compromising on performance or durability.

Types of Gears We Machine

At CNC Rapid, we have the capability to machine a wide variety of gears, including but not limited to:

- Spur Gears: These are the most common type of gears, used in a wide range of applications due to their simplicity and efficiency in transmitting motion between parallel shafts.

- Helical Gears: Known for their smooth and quiet operation, helical gears are widely used in automotive and industrial applications where noise reduction is important.

- Bevel Gears: These gears are used to transmit motion between intersecting shafts, commonly found in differential drives and mechanical systems that require torque transmission.

- Worm Gears: Worm gears are used in applications where high torque and low-speed transmission are needed, such as conveyor systems and gearboxes.

- Custom Gears: We offer fully customized gear machining services to meet the unique specifications of our clients. Whether you need non-standard gear sizes, unique gear profiles, or specialty materials, CNC Rapid can deliver tailored solutions.

Materials We Work With

We understand that different applications require different materials, and we are equipped to machine gears from a variety of materials, including:

- Steel: Known for its strength and durability, steel is a common material for gears used in heavy-duty applications.

- Stainless Steel: Stainless steel gears are highly resistant to corrosion, making them ideal for use in environments exposed to moisture, chemicals, or extreme temperatures.

- Aluminum: Aluminum gears are lightweight yet strong, often used in applications where reducing weight is critical without sacrificing performance.

- Brass: Brass is known for its low friction properties, making it a great choice for gears in applications that require smooth and quiet operation.

- Plastic: For lightweight and cost-effective gear solutions, we offer plastic gear machining, which is suitable for less demanding applications where metal gears are not required.

Custom Gear Machining Services

At CNC Rapid, we pride ourselves on delivering custom gear machining services that are tailored to the unique needs of our clients. Whether you need a prototype, small-batch production, or high-volume manufacturing, our team of skilled engineers and machinists work closely with you to ensure that every gear meets your exact specifications.

Our advanced CNC machines, combined with our expertise in gear machining, enable us to handle complex designs, tight tolerances, and challenging materials. We can work from your design drawings or help you optimize your gear designs for improved performance and manufacturability.

Applications of Our CNC Machined Gears

Our CNC machined gears are used across a wide range of industries, including:

- Automotive: High-precision gears for transmissions, engines, and differential systems.

- Aerospace: Lightweight and durable gears for aviation systems and spacecraft components.

- Industrial Machinery: Custom gears for heavy machinery, conveyors, and production equipment.

- Robotics: Precision gears for robotic systems requiring high accuracy and reliability.

- Electronics: Small gears for precision devices and mechanical components in consumer electronics.

Quality Assurance

At CNC Rapid, we are committed to delivering the highest quality gears that meet the stringent requirements of our clients. Every gear we machine undergoes rigorous quality control measures to ensure that it meets the exact specifications and tolerances required for its application. Our inspection processes include dimensional verification, surface finish checks, and gear tooth profile analysis to guarantee that each part performs as expected.

We use advanced measurement tools, such as coordinate measuring machines (CMM), to ensure that all critical dimensions are accurate and consistent. Our commitment to quality ensures that every gear we produce is ready for immediate use, delivering reliable performance in its intended application.

Why Choose CNC Rapid for Gear Machining?

Advanced CNC Technology

Our use of cutting-edge CNC machines and high-speed gear hobbing technology enables us to deliver high-precision gears with rapid turnaround times. The combination of speed, accuracy, and versatility allows us to meet the demands of even the most complex projects.

Expertise Across Materials and Gear Types

With extensive experience machining gears from a variety of materials, CNC Rapid is equipped to handle projects for any industry. From steel and aluminum to brass and plastic, we can create custom gears that meet your specific requirements.

Custom Solutions and Flexibility

We understand that every project is unique, and we offer fully customized gear machining solutions to meet your exact needs. Whether you need a standard gear type or a completely unique design, CNC Rapid can provide the expertise and flexibility to bring your project to life.

Let CNC Rapid be Your partner

CNC Rapid is a trusted partner for precision CNC gear machining, offering advanced high-speed gear hobbing services to meet the diverse needs of our clients. With our ability to machine gears from a wide range of materials and our commitment to quality, we deliver custom gear solutions that perform reliably across industries. Whether you need gears for automotive, aerospace, industrial machinery, or electronics applications, CNC Rapid has the expertise and technology to deliver high-quality results.

Contact CNC Rapid Today!

For high-precision CNC gear machining services, contact CNC Rapid today. Our team is ready to assist you with custom gear solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s machining capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!