DFM Rapid Limited is a leading provider of high precision CNC machining services. Our advanced CNC machines and experienced team of machinists allow us to produce precise and consistent parts, no matter the complexity or size of the project.

CNC machining is a process that uses computer-controlled machines to shape and finish a wide range of materials, including metals and plastics. At DFM Rapid, we specialize in providing high precision CNC machining services, which means we can produce parts with very tight tolerances and excellent surface finishes.

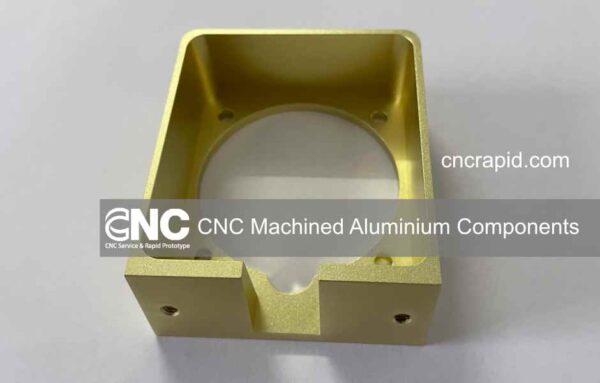

CNC Milling

CNC milling is a machining process that involves using a rotating cutting tool to remove material from a workpiece. The cutting tool is mounted on a CNC machine and is guided along a predetermined path to produce the desired shape. CNC milling is typically used to produce parts with complex geometries, such as those found in the aerospace, automotive, and medical industries.

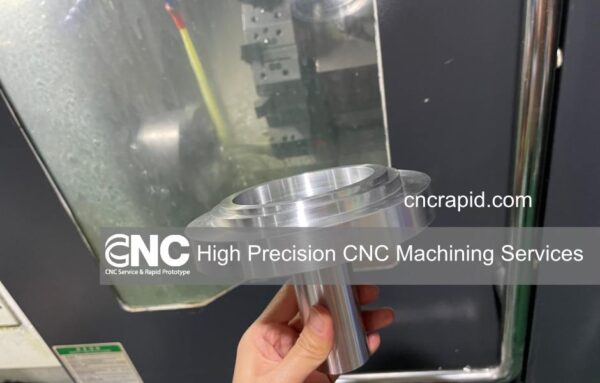

CNC Turning

CNC turning, on the other hand, is a machining process that involves rotating a workpiece on a lathe and using a cutting tool to remove material. This process is typically used to produce cylindrical parts, such as shafts, screws, and bearings. CNC turning allows for high precision and excellent surface finishes, making it well-suited for applications in industries such as aerospace, medical, and automotive.

Both CNC milling and CNC turning are versatile and widely used machining processes that can produce a wide range of parts with high precision and accuracy.

One of the key advantages of CNC machining is its ability to produce parts with high precision and repeatability. This is particularly important for industries that require precise and consistent parts, such as aerospace, medical, and automotive. With our high precision CNC machining services, we can help you produce parts that meet or exceed your specifications, every time.

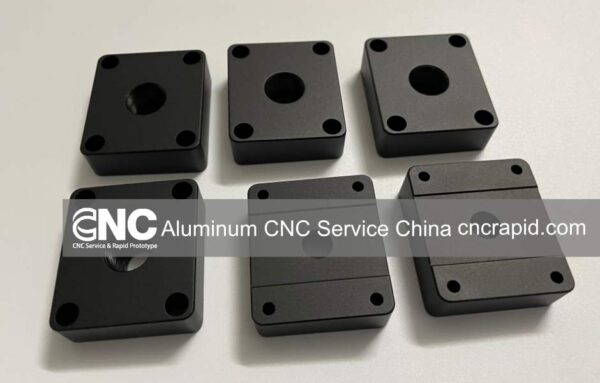

We also offer a range of surface finish options, including anodizing and powder coating. These finishes can help protect your parts from corrosion and wear, and they can also enhance their aesthetic appearance.

At DFM Rapid, we have experience working with a wide range of industries, including automotive, aerospace, medical, and more. We understand the unique requirements and challenges of each industry, and we’re committed to providing high-quality parts that meet or exceed your expectations.

The advantages of CNC Machining

- Precision and repeatability: CNC machining allows for very high precision and repeatability, making it well-suited for applications that require tight tolerances and consistent quality.

- Speed and efficiency: CNC machines are fast and efficient, allowing for quick turnaround times and high production rates.

- Versatility: CNC machining can be used to produce a wide range of parts with complex geometries and a variety of materials, including metals, plastics, and composites.

- Reduced production costs: CNC machining is often more cost-effective than traditional machining methods, especially for large production runs.

- Improved safety: CNC machines are typically safer to operate than manual machines, as they do not require operators to be in close proximity to the cutting tool.

Our CNC machining capabilities extend beyond just milling and turning. We also offer other services such as drilling, tapping, and boring, which allow us to produce parts with a wide range of features and geometry. Additionally, our experienced team of machinists can work with a variety of materials, including metals, plastics, and composites, to produce parts that meet your specific requirements.

In addition to our high precision CNC machining services, we also offer other value-added services such as engineering and design support, prototyping, and assembly. These services can help save you time and money by streamlining the entire manufacturing process, from concept to final product.

Whether you need a one-off prototype or a large production run, we’re here to help. Contact us today to learn more and request a quote.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!