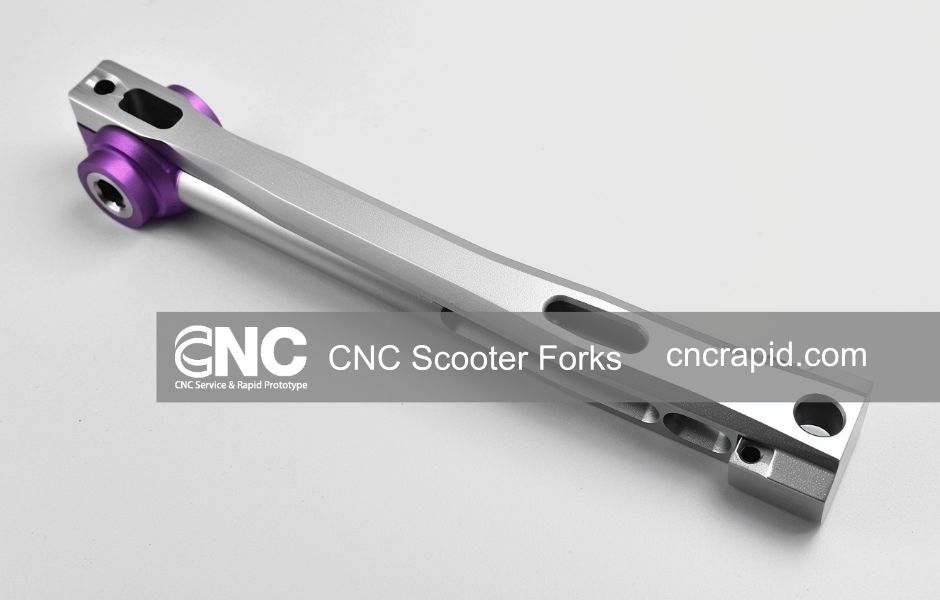

Aluminum CNC Scooter Forks are at the heart of scooter innovation, blending unmatched strength, lightweight design, and visual appeal. At CNC Rapid, we’ve used the power of advanced CNC machining to produce scooter forks that set new standards in the industry.

Why choose Aluminum in Scooter Forks

Aluminum stands out as a material of choice for scooter forks due to its exceptional strength-to-weight ratio, corrosion resistance, and ability to undergo precise machining. These properties are crucial for scooter forks that demand high strength for safety and lightweight for maneuverability. CNC machining aluminum allows for the creation of scooter forks that are not just functional but also aesthetically pleasing, catering to the modern scooter rider’s demand for performance and style.

The CNC Rapid Advantage

At CNC Rapid, our expertise in CNC machining transforms raw aluminum into scooter forks that are synonymous with precision and durability. Our advanced CNC machines, operated by skilled technicians, ensure that every scooter fork we produce meets stringent quality standards. Here’s why CNC Rapid stands out:

- Precision Engineering: Our aluminum CNC scooter forks are engineered with meticulous attention to detail. Through precise machining, we achieve tolerances that ensure a perfect fit and flawless function in scooter assemblies.

- Customization Capabilities: Understanding that each brand and scooter model has unique requirements, CNC Rapid offers customization services. Whether it’s specific dimensions, designs, or finishes, our CNC machining process can be tailored to meet your exact needs.

- Quality Assurance: At CNC Rapid, quality isn’t just a buzzword; it’s a promise. Our aluminum scooter forks undergo rigorous testing and quality checks to ensure they withstand the challenges of both competitive racing and everyday use.

- Rapid Prototyping to Production: Speed to market is crucial in the fast-paced scooter industry. CNC Rapid’s rapid prototyping services allow you to swiftly move from concept to production, ensuring you stay ahead of the competition.

- Sustainability Focus: We are committed to sustainable manufacturing practices, recognizing the importance of environmental responsibility in today’s world. Our CNC machining process is designed to minimize waste and maximize efficiency, reflecting our dedication to sustainability.

Elevating the Scooter Experience with CNC Rapid

Choosing aluminum CNC scooter forks from CNC Rapid means investing in performance, reliability, and aesthetics. Whether you’re a scooter manufacturer seeking to elevate your product line or a custom scooter builder looking for the highest quality components, CNC Rapid is your partner in innovation.

Our commitment to excellence, combined with our passion for advancing scooter technology, makes us the ideal choice for your aluminum CNC scooter fork needs. Experience the CNC Rapid difference today and elevate your scooter offerings to new heights.

Join the CNC Rapid Journey

At CNC Rapid, we’re more than just a machining company; we’re innovators, craftsmen, and enthusiasts dedicated to pushing the boundaries of what’s possible in scooter manufacturing. Explore our website to learn more about our aluminum CNC scooter fork capabilities and discover how we can help you achieve your manufacturing goals.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!