The Significance of ABS in CNC Machining:

ABS plastic, with its blend of mechanical robustness, aesthetic versatility, and machinability, stands out as a preferred material in CNC machining. By choosing ABS plastic, manufacturers and engineers are ensuring the production of high-quality, durable, and aesthetically pleasing components, aligning with sustainable manufacturing practices and catering to diverse industry applications.

Acrylonitrile Butadiene Styrene (ABS), a thermoplastic polymer, has become a cornerstone in CNC machining, offering a balance of strength, thermal resistance, and cost-effectiveness. This article explores the intrinsic properties, applications, and the pivotal role ABS plays in CNC machining, providing insights for design engineers in various industries.

Intrinsic Properties of ABS Plastic

ABS plastic is renowned for its impressive mechanical properties, providing a robust material that combines toughness with excellent impact resistance. Its ability to withstand varying temperatures without compromising its structural integrity makes it a preferred choice for numerous applications, from automotive components to electronic housings.

Machinability: A Key Advantage

The machinability of ABS sets it apart in CNC machining. Its ability to be easily cut, carved, and molded ensures precision in manufactured parts, while its thermal stability and durability ensure that the machined parts maintain their form and function in diverse application environments.

Diverse Applications Across Industries

- Automotive Industry: ABS is utilized for creating components like dashboards, wheel covers, and more due to its durability and aesthetic versatility.

- Consumer Electronics: ABS finds its place in manufacturing components such as keyboard keys, electronic housings, and more, providing a balance of strength and aesthetic appeal.

- Medical Devices: ABS is employed in creating durable and safe components for various medical devices, ensuring safety and compliance with medical standards.

Designing with ABS: Considerations and Tips

When designing with ABS, it’s imperative to consider its mechanical properties, thermal stability, and aesthetic capabilities. Ensuring that the design is optimized for its machinability and durability will result in components that are not only functional but also visually appealing and reliable.

Sustainability and ABS

ABS aligns with sustainable manufacturing practices due to its recyclability. The material can be reprocessed and reused, reducing waste and promoting environmentally responsible manufacturing.

ABS Plastic: A Material of Choice

ABS plastic emerges as a material of choice in CNC machining, offering a blend of machinability, durability, and aesthetic versatility. Its wide-ranging applications across various industries attest to its reliability and effectiveness, making it a preferred material among design engineers and manufacturers alike.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

Custom CNC Lathe Machined ABS Plastic Parts by CNC Rapid

ABS (Acrylonitrile Butadiene Styrene) plastic stands out as a preferred material, particularly when precision machining is required. At CNC Rapid, we specialize in producing high-quality custom ABS plastic parts using advanced CNC lathe machining. [...]

Custom CNC Plastic and Metal Parts by CNC Rapid

At CNC Rapid, we specialize in providing high-quality, custom CNC plastic and metal parts for a wide range of industries, including automotive, electronics, and industrial applications. With years of expertise in precision machining, we ensure [...]

Precision ABS Plastic CNC Machining Services by CNC Rapid

At CNC Rapid, we are committed to providing precision ABS plastic CNC machining services that meet the highest standards of quality and performance. Whether you need a single prototype or large-scale production, our team is [...]

Custom Plastic Parts

CNC custom plastic parts are made by using CNC machines to precisely machine plastic materials into complex shapes. CNC machining is a versatile process that can be used to create a wide variety of plastic [...]

Plastic CNC Service

Plastic CNC Service. There are many plastics that are suitable for CNC machining, if you have any CNC projects that need plastic material, please consider us as your CNC machining shop. And plastics have a [...]

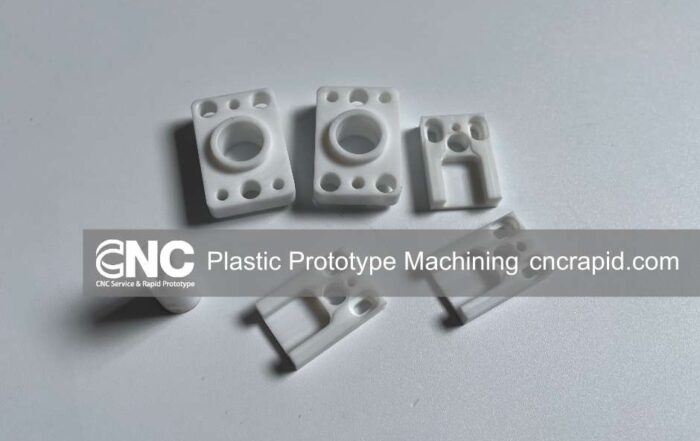

Plastic Prototype Machining

Plastic Prototype Machining. From 1 to 10000+ parts. We can provide CNC prototyping services & Low volume CNC machining. We can make a machining plan according to your needs, and our experienced engineers can provide [...]