Heat sinks CNC machining is a leading solution for thermal management in electronics. With the continuous advancement of electronic devices towards higher power and smaller sizes, managing the excess heat generated has become a critical challenge. This is where CNC (Computer Numerical Control) machining of heat sinks comes into play, offering precision, efficiency, and customization that traditional methods can hardly match.

What is CNC Machining for Heat Sinks?

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. When it comes to heat sinks, CNC machining allows for the precise cutting of materials into specific designs and dimensions, catering to the unique thermal management needs of various electronic devices. This method offers unparalleled accuracy, repeatability, and flexibility in producing heat sinks from metals like aluminum and copper, which are known for their excellent thermal conductivity.

The Significance of Heat Sinks CNC Machining in Electronics:

Enhanced Thermal Performance:

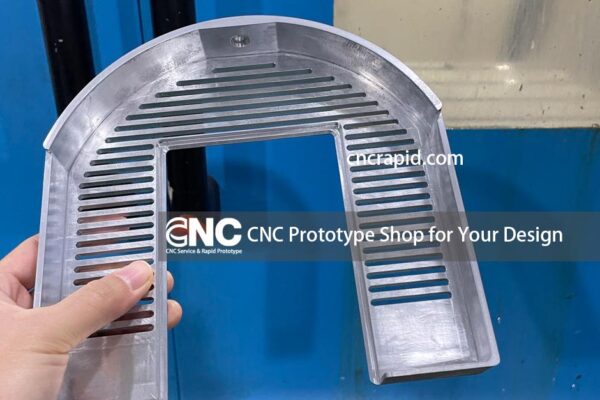

CNC machining enables the creation of complex geometries and surfaces that significantly improve the thermal performance of heat sinks. Features such as micro-fins and intricate channels that increase surface area and air turbulence can be precisely machined, leading to more efficient heat dissipation.

Customization and Flexibility:

One of the most significant advantages of CNC machining is its ability to produce custom-designed heat sinks tailored to specific applications. Whether it’s for a high-performance CPU, LED lighting, or power electronics, CNC machining can create optimized heat sinks that fit the exact dimensions and thermal requirements of the device.

Material Efficiency and Sustainability:

CNC machining is known for its material efficiency, reducing waste by precisely cutting materials according to the design specifications. This not only saves on material costs but also aligns with sustainability goals by minimizing scrap.

Rapid Prototyping and Production:

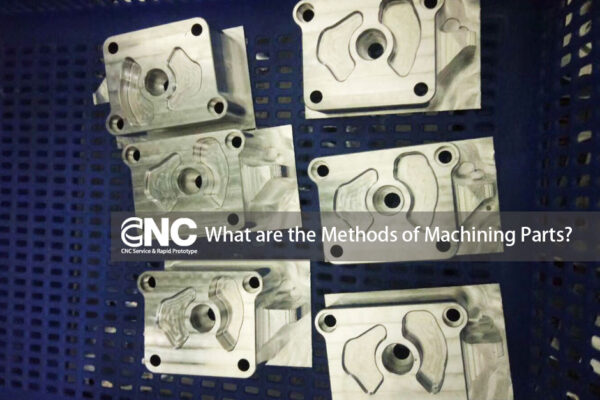

The speed and flexibility of CNC machining make it ideal for both prototyping and mass production. Manufacturers can quickly iterate designs to find the most effective thermal solution and then scale up production as needed without significant downtime or tooling changes.

Why Choose CNC Rapid

CNC Rapid specializes in the production of heat sinks through advanced CNC machining techniques, catering to the ever-evolving demands of the electronics industry.

Whether you’re in need of a custom-designed heat sink for high-performance computing, LED lighting, or power electronics, CNC Rapid has the expertise and capabilities to deliver products that excel in efficiency and reliability. Our commitment to innovation, precision, and customer satisfaction makes us a trusted partner in your journey towards optimal thermal management.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!