When it comes to keeping our electronic devices safe, “Enclosures for Electronic Devices” play a huge role. These are the protective covers that shield our gadgets from dust, water, and accidental drops. But have you ever wondered how these critical components are made to fit so perfectly and protect so well? The answer lies in a high-tech process known as CNC machining. This process is key to creating precise, durable, and high-quality enclosures for electronic devices.

Enclosure for Electronic Devices

Enclosure for electronic devices are not just about making the devices look good. They serve critical protective functions by shielding the electronic components from environmental hazards and mechanical impacts. These enclosures also aid in heat management and can enhance the device’s usability and aesthetic appeal. Given their importance, the production of these enclosures requires a method that ensures accuracy, reliability, and quality.

CNC Machining

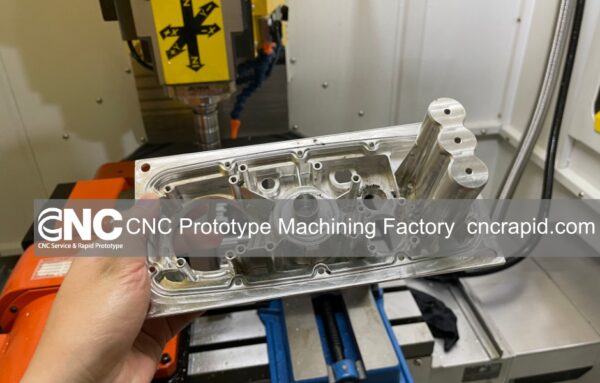

CNC machining stands out as the manufacturing process of choice for enclosure for electronic devices.

- Precision and Quality: CNC machining offers exceptional precision, making it possible to produce enclosures that fit electronic devices like a glove. This precision ensures that every enclosure can protect the device’s sensitive components effectively.

- Material Flexibility: This process allows manufacturers to work with a wide range of materials, from metals to plastics, offering the flexibility to choose the best material for each device’s specific needs.

- Design Freedom: CNC machining provides the freedom to create complex designs that can meet functional requirements and aesthetic desires. This means that enclosures can be tailor-made to enhance the device’s features and appeal to consumers.

- Speed and Efficiency: With CNC machining, production can be ramped up quickly, allowing for faster turnaround times from design to finished product. This efficiency helps manufacturers meet market demands and reduces the time it takes for new devices to reach consumers.

Why Choose CNC Rapid for Your Enclosures

Our CNC machining services specialize in creating high-quality enclosures for electronic devices. We understand the importance of these enclosures in protecting and enhancing electronic devices. Our CNC equipment and skilled team ensure that each enclosure is manufactured to meet the highest standards of precision, durability, and aesthetics. Whether you’re in the initial stages of design or ready for mass production, our services are designed to bring your vision to life with efficiency and excellence.

As a provider of CNC machining services, we are committed to supporting the production of superior enclosures that meet the evolving needs of electronic devices and their users. Together, let’s create enclosures that not only protect but also elevate the value of electronic devices.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!