The Significance of PMMA (Acrylic) in CNC Machining:

PMMA’s versatility, combined with its superior mechanical and optical properties, makes it an invaluable material in the world of CNC machining. Its adaptability across various industries, from optics to healthcare, underscores its significance in modern engineering and design. As CNC machining continues to evolve, PMMA’s role as a go-to material for precision components is set to grow.

Polymethyl methacrylate (PMMA), commonly known as acrylic, is a transparent thermoplastic that has carved a niche for itself in the realm of CNC machining. Its unique blend of optical clarity, mechanical properties, and thermal stability makes it a preferred choice for a plethora of applications.

Molecular Structure and Properties

- Molecular Composition: PMMA is a polymer derived from methyl methacrylate (MMA) monomer. Its linear structure is responsible for its rigidity and glass-like clarity.

- Thermal Stability: With a melting point of approximately 160°C (320°F), PMMA can withstand elevated temperatures without significant degradation.

- Density: Typically, PMMA has a density of 1.18 g/cm³, which is less than half of that of glass.

Mechanical and Optical Characteristics

- Tensile Strength: PMMA exhibits a tensile strength of 70-130 MPa, making it robust for various applications.

- Refractive Index: With a refractive index of 1.49, PMMA is excellent for optical applications, offering clarity and light transmission comparable to that of glass.

- Hardness: On the Rockwell M scale, PMMA usually scores around M-95.

Machining Insights

- Tool Selection: Carbide-tipped tools are recommended for machining PMMA to achieve smooth finishes and prevent chipping.

- Coolant Use: A water-soluble coolant aids in achieving better finishes and prolongs tool life.

- Drilling: When drilling PMMA, it’s crucial to withdraw the drill frequently to prevent heat buildup.

PMMA in CNC Machining

- Feed Rates: Slower feed rates are preferable to prevent overheating and melting.

- Surface Finishing: PMMA can be polished to achieve a high-gloss finish, enhancing its natural clarity.

Applications in Engineering and Design

- Optical Lenses: Due to its high light transmissibility and clarity, PMMA is widely used in manufacturing lenses for eyewear and optical instruments.

- Medical Devices: Its biocompatibility makes PMMA suitable for various medical applications, including surgical instruments and dental prosthetics.

- Architectural Glazing: PMMA sheets are used as a lightweight, shatterproof alternative to glass in architectural applications.

Environmental Considerations

- Recyclability: PMMA can be recycled, though the process is more energy-intensive compared to other plastics.

- Biocompatibility: PMMA doesn’t leach harmful chemicals, making it safe for medical and food-contact applications.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

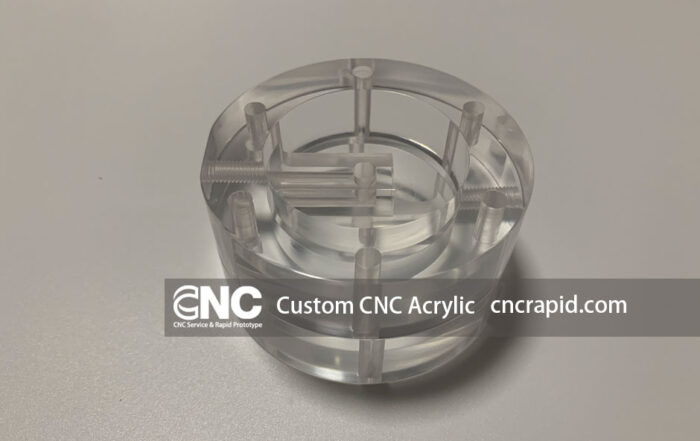

2026 Custom Acrylic CNC Service for All Industries at CNC Rapid

At CNC Rapid, we specialize in providing Custom Acrylic CNC Service that caters to a wide range of industries. In 2026, we continue to push the boundaries of excellence and innovation, ensuring that your projects [...]

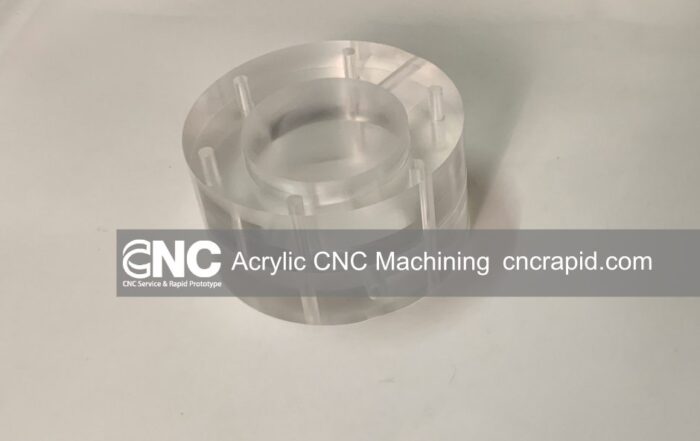

Acrylic CNC Machining

Acrylic CNC Machining. Acrylic is a suitable material for CNC machining and can be used to create a wide range of products with precise dimensions and smooth finishes. Acrylic, also known as polymethyl methacrylate (PMMA), [...]

CNC Rapid Acrylic Machining Services

Acrylic machining services. Welcome to DFM Rapid, also known as CNC Rapid, where we specialize in Acrylic CNC Machining Services. Our success lies not just in delivering high-quality services, but also in our ability [...]

Custom CNC Acrylic Solutions 2026 by CNC Rapid

As we step into 2026, CNC Rapid continues to lead the way in delivering high-quality custom CNC acrylic solutions for industries worldwide. Whether you're an engineer, product designer, or CNC industry professional, our cutting-edge services [...]