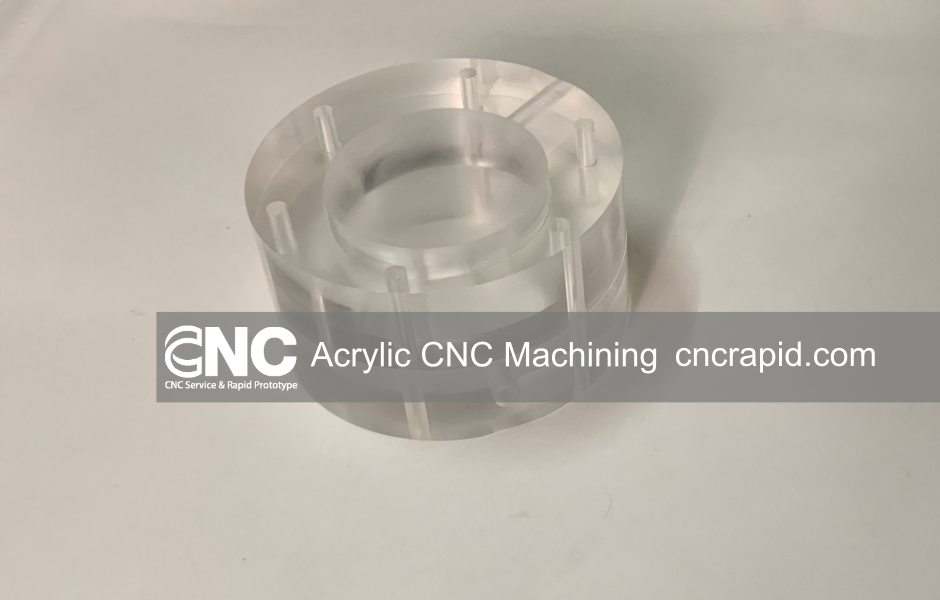

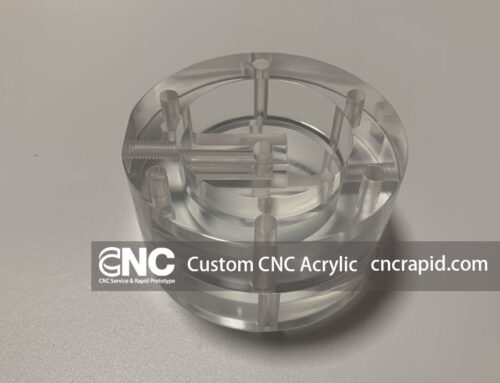

Acrylic CNC Machining. Acrylic is a suitable material for CNC machining and can be used to create a wide range of products with precise dimensions and smooth finishes. Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent plastic material that is often used in place of glass for a variety of applications. It is a popular choice for CNC machining because it is easy to work with and can be used to create a wide range of products, including signs, displays, and decorative pieces.

One of the benefits of using acrylic for CNC machining is that it can be easily shaped and formed into a variety of shapes and sizes using CNC machines.

CNC machining, or computer numerical control machining, is a manufacturing process in which a machine is controlled by a computer program to create precise cuts and shapes in a variety of materials. The process involves the use of specialized CNC machines, such as a mill or router, to shape the material according to a specific set of instructions. CNC machining is widely used in the manufacturing industry to create a variety of products, including automotive parts, aerospace components, and medical devices. It is a fast and accurate method of production that allows for the creation of complex and detailed parts with a high degree of precision. CNC machining can be used to work with a wide range of materials, including metals, plastics, and composites. It is a flexible process that allows for the creation of a wide range of products, from simple to complex shapes. CNC machining is often used in combination with other manufacturing processes, such as 3D printing and injection molding, to create finished products.

Acrylic can be machined using CNC machines in a variety of ways, including milling, drilling, and cutting, turning. The specific technique used will depend on the desired shape and size of the final product.

During the CNC machining process, a block of acrylic is secured to the bed of a CNC mill or CNC turn and is then shaped using a rotating cutting tool. The cutting tool is guided by the computer program and follows a precise set of instructions to create the desired shape.

- Milling is a common technique used to shape acrylic using CNC equipment. In this process, the cutting tool rotates and moves along multiple axes to remove material from the acrylic and create the desired shape. Milling can be used to create a wide range of shapes, including complex and detailed designs.

- Drilling is another technique that can be used to create holes in acrylic using CNC equipment. In this process, a rotating drill bit is used to remove material and create the desired hole.

- Cutting is a simple technique that involves using a rotating blade to cut acrylic into a specific shape or size. This can be done using a variety of blade types and is often used to create straight edges or simple shapes.

- During the CNC turning process, the acrylic is rotated along its axis while the cutting tool remains stationary. The cutting tool is then used to remove material from the surface of the acrylic to create the desired shape. CNC turning can be used to create a wide range of shapes, including cylindrical parts with precise dimensions and smooth finishes.

Acrylic can be easily machined using CNC machines to create a wide range of precise and detailed products/parts.

DFM Rapid – a leading provider of acrylic CNC machining services. We specialize in using advanced CNC machines to create precise and detailed products/parts from acrylic and other materials. Our team of experienced machinists is dedicated to delivering high-quality products and exceptional customer service. Whether you need a single prototype or large-volume production runs, we have the capabilities to meet your needs. Contact us today to learn more about how our acrylic CNC machining services can benefit your business.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!