The Significance of 6061-T6 Aluminum in CNC Machining:

6061-T6 aluminum is a premier choice in CNC machining due to its optimal balance of strength, machinability, and weldability. Its versatility and durability make it a go-to material for precision components across various industries.

6061-T6 Aluminum Alloy: The Premier Choice for CNC Machining

Material selection plays a pivotal role in determining the quality and efficiency of the final product. Among the myriad of materials available, 6061-T6 aluminum alloy stands out as a top choice for engineers and designers alike. This article delves into the attributes and advantages of this alloy, specifically tailored for product design engineers.

Fundamental Properties of 6061-T6 Aluminum Alloy:

- Chemical Composition & Microstructure: Comprising primarily of aluminum, with magnesium and silicon as its major alloying elements, 6061-T6 offers a balanced combination of mechanical robustness and corrosion resistance.

- Physical & Mechanical Characteristics: Boasting a density of 2.70 g/cm³, a melting point of 585°C, and impressive tensile strength, this alloy is both lightweight and durable.

|

|

| CNC Rapid |

Why 6061-T6 is the Ideal Choice for CNC Machining:

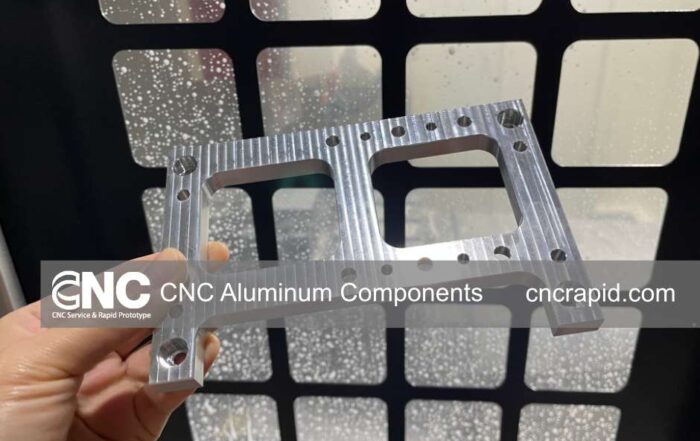

- Machinability: Whether it’s milling, turning, or drilling, 6061-T6 exhibits excellent machinability, ensuring precision and quality in the final product.

- Surface Treatment Options: From anodizing to painting and electroplating, this alloy offers a plethora of surface treatment alternatives, enhancing both its aesthetic and functional attributes.

- Welding & Joining Capabilities: With superior weldability, especially in gas tungsten arc welding and metal inert gas welding, 6061-T6 can be seamlessly integrated into complex structures.

|

|

| CNC Rapid |

Practical Applications of 6061-T6 in Product Design:

- Common Product & Component Examples: From aerospace components to automotive chassis and electronic device casings, the versatility of 6061-T6 is evident in its widespread use.

- Advantages Over Other Materials: When pitted against other materials, the alloy’s strength-to-weight ratio, corrosion resistance, and ease of machining make it a clear frontrunner.

Design Recommendations:

- Maximizing the Potential of 6061-T6: Consider the alloy’s strengths and limitations when designing. For instance, leverage its excellent machinability for intricate designs but be mindful of its thermal limits.

- Common Design Pitfalls & How to Avoid Them: Overcomplicating designs or not accounting for the alloy’s specific heat treatment can lead to inefficiencies. It’s crucial to understand the material thoroughly to avoid such pitfalls.

|

|

6061 Aluminum vs. 6061-T6 Aluminum

| Feature/Property | 6061 Aluminum | 6061–T6 Aluminum |

|---|---|---|

| Heat Treatment State | Basic state, no specific heat treatment applied. | Undergone solution heat treatment and artificially aged to achieve peak strength. |

| Mechanical Properties | Moderate mechanical properties. | Enhanced tensile strength and hardness due to T6 treatment. |

| Applications | Moderate strength applications, potential heat treatment later. | Demanding applications like aerospace components, automotive parts, CNC designs. |

| Machinability | Good machinability in its base state. | Increased hardness might pose challenges in high precision machining. |

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

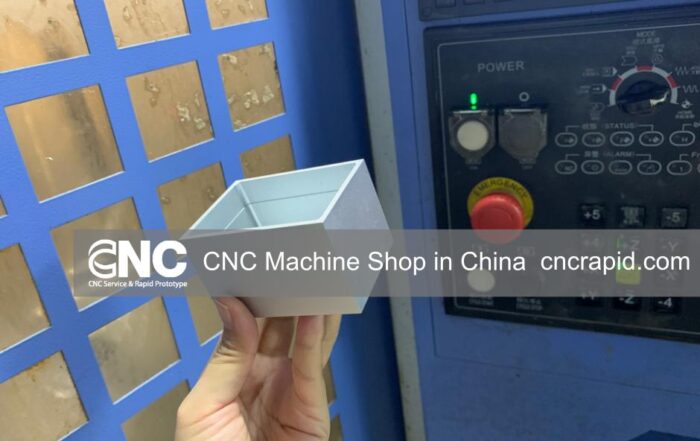

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]