Aluminum brackets play a crucial role in electronics assembly by providing reliable support and precise positioning. CNC Rapid specializes in creating custom aluminum brackets through CNC machining, precisely meeting your project’s requirements. Our brackets offer a perfect balance of strength, accuracy, and lightweight characteristics.

Why Aluminum Brackets Are Ideal for Electronics

Aluminum brackets have several advantages for electronics:

- Lightweight: Reduces the overall weight of products, improving portability.

- Strength and Stability: Provides essential support and durability.

- Corrosion Resistance: Suitable for both indoor and outdoor electronic devices.

- Efficient Machining: Easily machined to achieve precise specifications and intricate designs.

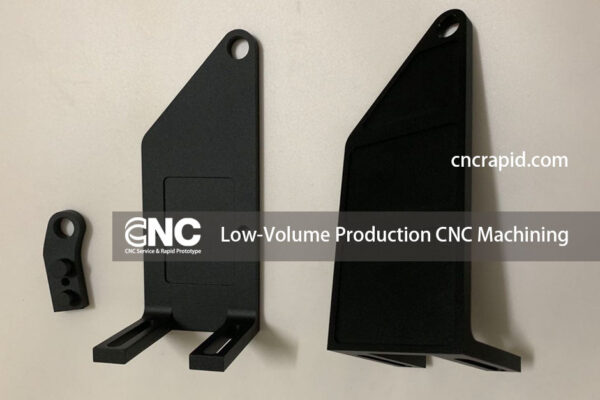

Detailed front view highlighting precision CNC machining and the smooth, professional finish.

Best Aluminum Materials for Your CNC Brackets

Selecting the right aluminum alloy can significantly impact the performance and durability of your brackets. Here are our top recommendations:

- 6061 Aluminum Alloy: Versatile, affordable, excellent machinability, and suitable for most electronics projects.

- 7075 Aluminum Alloy: Superior strength and ideal for brackets used under high stress.

- 5052 Aluminum Alloy: Exceptional corrosion resistance, perfect for outdoor or harsh environments.

Side view showing precise hole placements and cleanly machined edges, essential for accurate assembly.

Applications of Custom Aluminum Brackets in Electronics

Our CNC machined brackets are widely used across various electronic applications, including:

- Circuit board mounting

- Sensor housings

- Device enclosures

- Display screen supports

- Robotics and automation components

Sustainability and Efficiency in CNC Machining

CNC Rapid prioritizes sustainability and efficiency. CNC machining aluminum brackets reduces material waste through precise cutting techniques. Additionally, aluminum is recyclable, supporting environmentally friendly manufacturing practices.

Back view showcasing conveniently placed mounting features for simplified and secure installation.

Partner with CNC Rapid for Your Custom Bracket Needs

Choosing CNC Rapid means partnering with an experienced team committed to quality, precision, and timely delivery. Our advanced CNC machining equipment and skilled professionals ensure your custom aluminum brackets perfectly match your project’s specifications.

Reach out to CNC Rapid today for tailored CNC machined aluminum brackets to elevate your electronics assembly projects.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!