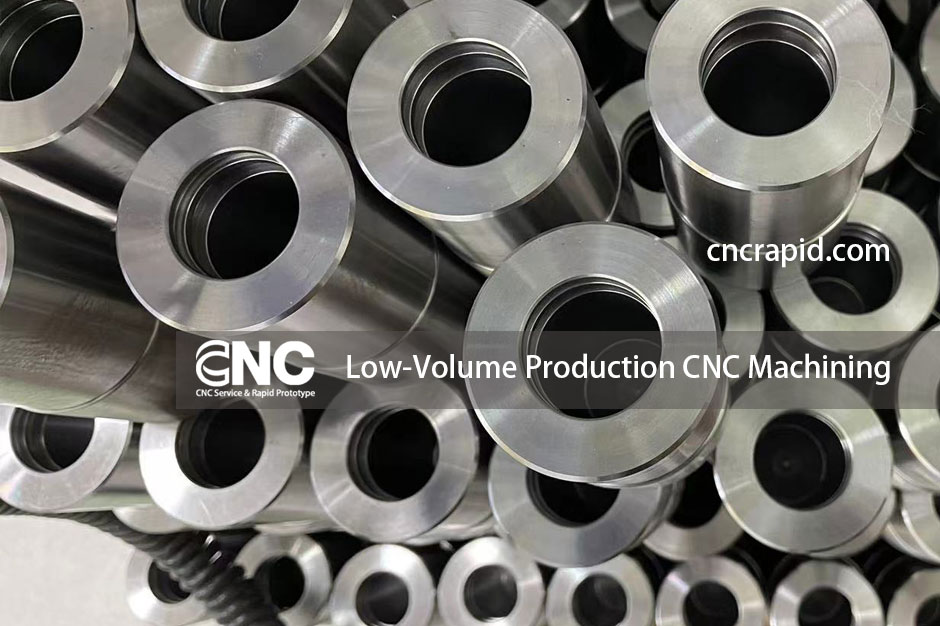

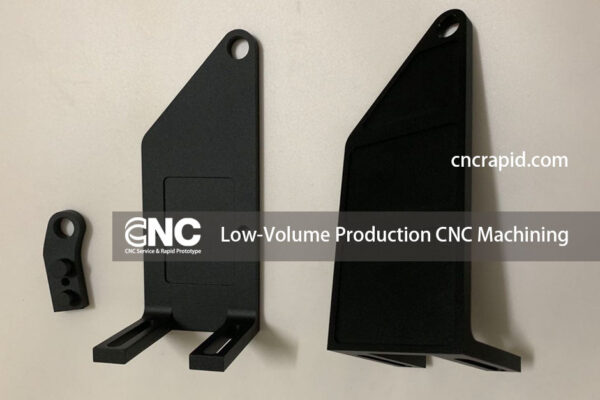

Low-volume production CNC machining is a manufacturing process that uses of CNC machines to produce a small number of high-quality parts. Compared to traditional manufacturing methods, which often require costly tooling and set-up fees, low-volume production CNC machining is a cost-effective solution for producing parts with complex geometries, tight tolerances, and high accuracy.

Advantages of Low-volume production CNC machining

- Precision: CNC machines are highly accurate and can produce parts with a high degree of precision, ensuring that each part is exactly the same.

- Speed: CNC machines can produce parts quickly and efficiently, without the need for expensive tooling or long lead times. This is particularly important for low-volume production, where time is of the essence.

- Flexibility: CNC machines can be programmed to produce a wide range of parts and components, making them ideal for low-volume production where there may be a variety of parts needed.

- Consistency: CNC machines can produce parts with consistent quality, reducing the risk of errors or defects.

- Cost-effectiveness: Low-volume production CNC machining is often more cost-effective than traditional manufacturing methods, especially for small quantities of parts.

- Scalability: CNC machines can easily be reprogrammed to produce larger quantities of parts if needed, making them scalable and adaptable to changing production needs.

Type of CNC Machine

CNC Milling machines: Milling machines use rotary cutters to remove material from a workpiece, producing a variety of shapes and sizes. They are ideal for producing complex parts with high precision and accuracy, and can be used with a wide range of materials.

CNC Lathes: Lathes are used to shape and cut cylindrical workpieces, such as shafts or rods. They can produce parts with high precision and accuracy, and are often used in the production of metal components.

Common materials of Low-volume production CNC machining

- Metals: CNC machining can be used with a range of metals, including aluminum, steel, brass, copper, and titanium. Metals are often used in the production of aerospace and automotive components, where strength and durability are important.

- Plastics: Plastics such as ABS, polycarbonate, and nylon are commonly used in low-volume production, as they are lightweight and can be easily machined. Plastics are often used in the production of consumer products, electronics, and medical devices.

The choice of material will depend on the specific needs of the project, including strength, durability, and aesthetics. CNC machining offers flexibility in the selection of materials, allowing manufacturers to choose the best material for their specific needs.

|

|

Industries and Applications of Low-volume production CNC machining

- Automotive: CNC machining is used in the production of automotive components, such as engine parts, transmission components, and chassis components. CNC machining allows for high accuracy and consistency, ensuring that each component meets the strict quality standards of the automotive industry.

- Electronics: CNC machining is used to produce a wide range of electronic components, such as enclosures, connectors, and heat sinks. CNC machining allows for high accuracy and consistency, ensuring that each component meets the specific requirements of the electronics industry.

- Medical devices: CNC machining is used to produce a wide range of medical devices, such as implants, surgical instruments, and prosthetics. CNC machining allows for high precision and accuracy, ensuring that each device meets the exacting standards of the medical industry.

- Consumer products: CNC machining is used in the production of a wide range of consumer products, such as electronics, toys, and household appliances. CNC machining allows for high flexibility and scalability, making it ideal for low-volume production runs of niche products.

- Defense and military: CNC machining is used in the production of a wide range of defense and military components, such as missile components, weapon systems, and armored vehicles. CNC machining allows for high precision and accuracy, ensuring that each component meets the exacting standards of the defense and military industries.

- Jewelry: CNC machining is used in the production of high-end jewelry, allowing for the creation of intricate and complex designs. CNC machining allows for high precision and accuracy, ensuring that each piece of jewelry meets the exacting standards of the jewelry industry.

- Tooling: CNC machining is used in the production of tooling components, such as dies, molds, and jigs. CNC machining allows for high precision and accuracy, ensuring that each tooling component meets the specific requirements of the manufacturing process.

- Prototyping: CNC machining is commonly used in the prototyping process, allowing for the creation of functional prototypes that can be used for testing and validation. CNC machining allows for high flexibility and scalability, making it ideal for the iterative design process.

Low-volume production CNC machining is a cost-effective solution for producing high-quality parts with precision, speed, and flexibility. By using CNC machines, various materials such as metals, plastics, and composites can be transformed into complex shapes and parts with accuracy and consistency. This technology has found applications in various industries such as aerospace, automotive, and medical device manufacturing, where it has significantly reduced the cost of production.

Why Choose DFM Rapid?

We specialize in Low-Volume Production CNC Machining, utilizing advanced CNC machines and technologies to produce high-quality parts at a competitive price.

We understand the importance of quality control and ensure that each part undergoes rigorous testing and inspection to guarantee that it meets the highest industry standards. Our commitment to quality, reliability, and efficiency has made us the preferred choice for many businesses in various industries, including electronics, automotive, and medical device manufacturing.

Whether you need a small quantity of parts or a large production run, our CNC shop can provide the perfect solution for your manufacturing needs. We pride ourselves on delivering exceptional results with fast turnaround times and competitive pricing.

Choose us for your Low-Volume Production CNC Machining needs, and let us help you achieve your production goals. Contact us today to learn more about our services and how we can help you.

Contact us

If you need Metal & Plastic CNC Machining Parts for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!