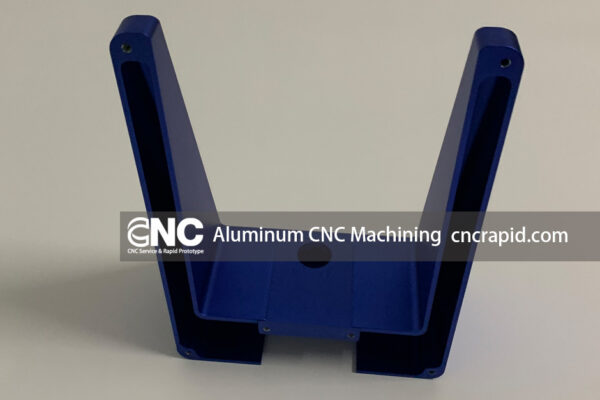

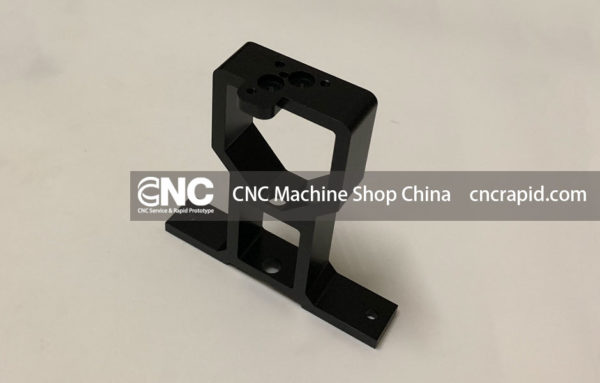

At CNC Rapid, we provide custom CNC parts that meet the demands of engineers, designers, and product developers around the world. Whether you need a one-off prototype or a batch of production-ready components, our CNC machining services deliver precision, reliability, and speed.

Custom CNC parts are special parts made by a CNC machine that can cut and shape materials very accurately. The machine is guided by computer software that follows a 3D model of the part.

Why Choose Custom CNC Parts?

Every project is unique. Standard parts cannot always meet the functional or design requirements of modern products. That is why more companies turn to custom CNC machining:

- Exact fit and function – parts made according to your drawings.

- Material flexibility – from aluminum and stainless steel to engineering plastics.

- Fast turnaround – receive your parts in days, not weeks.

- Scalable production – from single prototypes to hundreds of parts.

By choosing CNC Rapid, you get the confidence that your designs will be manufactured to the highest standards.

Prototyping with Custom CNC Parts

Rapid prototyping helps reduce development risks and speed up time-to-market. CNC machining is an ideal process for prototypes because it provides:

- High accuracy – critical dimensions maintained within tight tolerances.

- Real material performance – test with the same materials as final products.

- Design flexibility – quick modifications for new iterations.

- Surface finishes – from as-machined to anodized and polished.

With our team, you can turn your CAD files into real functional parts faster than ever.

Low-Volume CNC Production

Not every project requires mass production. For many clients, small batch production is the most cost-effective solution. CNC Rapid offers low-volume manufacturing that helps you:

- Test your product before large-scale investment.

- Respond to small market demands quickly.

- Avoid high tooling costs from injection molding or die casting.

- Maintain consistent quality with strict inspections.

Our flexible approach allows you to scale production according to your needs.

We offer a wide range of CNC machining parts and are open to manufacturing custom CNC machining parts according to your unique requirements. Our CNC machining services feature personalized customer service for made-to-order parts and components. We provide turning, milling, drilling, tapping, boring, and grinding for a variety of materials.

Applications of Custom CNC Parts

At DFM Rapid, also known as CNC Rapid, we provide you with professional one-stop service in product development and volume production, from rapid prototyping to CNC machining production. Custom CNC parts are used in a wide range of industries, including electronics, automotive, aerospace, and medical devices. They provide high precision and consistency, making them ideal for both prototyping and production runs.

CNC machining is a practical option for everything from prototype manufacturing to production runs. We are a one-stop shop for custom machining and manufacturing.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Get in Touch

If you need Metal & Plastic parts machined for Custom Aluminum Milling prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time.