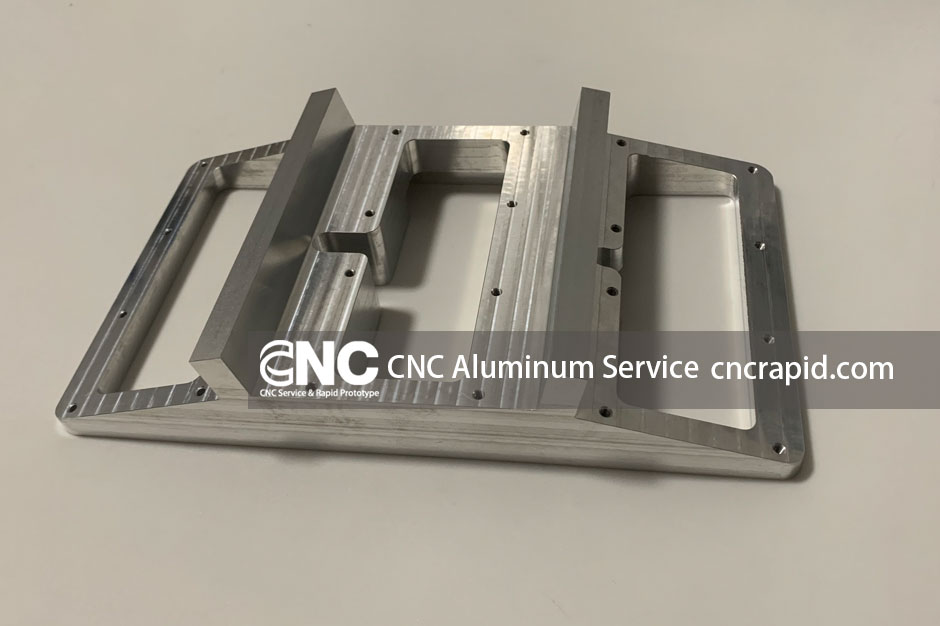

CNC aluminum service is an advanced manufacturing process that utilizes computer-controlled machines to create precise and accurate parts from aluminum materials. This cutting-edge technology is increasingly important for manufacturers across a variety of industries, as it offers numerous benefits over traditional manufacturing methods such as casting or stamping.

|

|

So why is CNC aluminum service so important for manufacturing needs? Simply put, it offers a range of benefits that can help improve product quality, reduce costs, and speed up time to market.

7 Benefits of Using CNC Aluminum Service for Your Manufacturing Needs

- Precision and Accuracy:

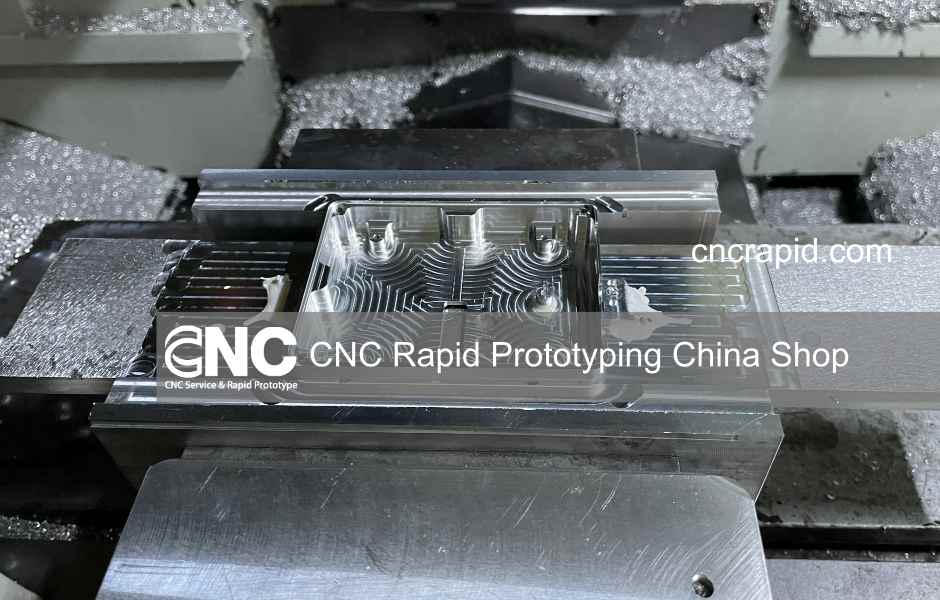

CNC aluminum service provides high precision and accuracy, ensuring that each part is manufactured to exact specifications. This level of precision is achieved through the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which guides the CNC machine in cutting and shaping the aluminum material. This leads to consistent, high-quality parts that meet strict industry standards. - Cost-effectiveness:

CNC aluminum service can be a cost-effective solution for manufacturing needs, as it eliminates the need for tooling or molds, which can be expensive and time-consuming to produce. Additionally, CNC machines can work around the clock, allowing for high-volume production runs with minimal labor costs. This can lead to significant savings for manufacturers, especially for high-volume production runs. - Versatility:

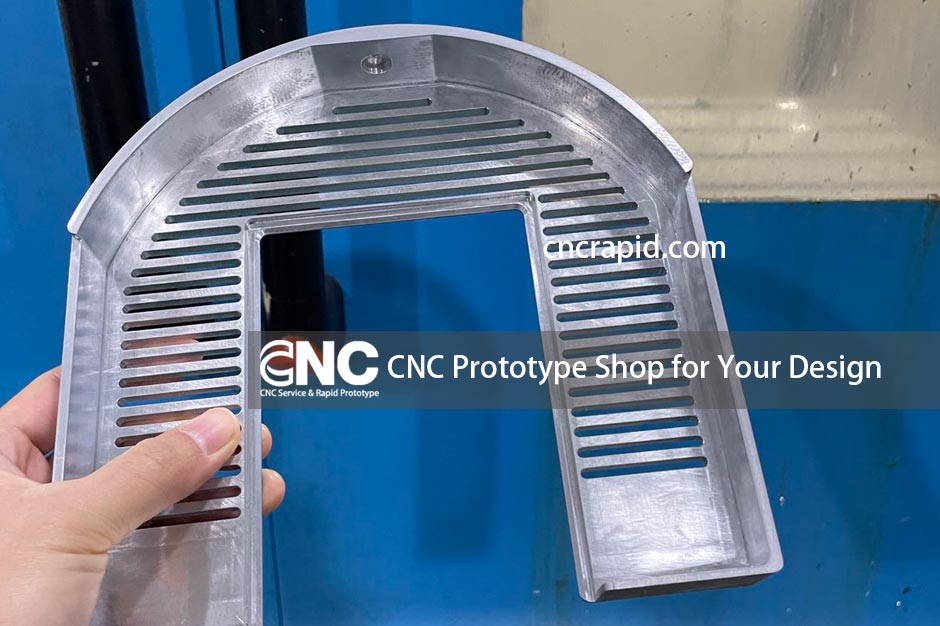

CNC aluminum service is a versatile manufacturing method, as it can be used to produce a wide range of parts with varying complexities and sizes. Whether you need a simple bracket or a complex component with intricate geometries, CNC aluminum service can meet your needs. This versatility is particularly useful for industries such as aerospace, automotive, and medical, where parts often have unique shapes and sizes. - Time Savings:

CNC aluminum service can help save time in the manufacturing process, as it eliminates the need for manual labor and can produce parts quickly and accurately. Additionally, CNC machines can work 24/7, allowing for faster turnaround times and reduced lead times. This can be especially important for industries with short product lifecycles or tight deadlines. - Consistency and Reproducibility:

CNC aluminum service can create highly consistent and reproducible parts, ensuring that each part is the same as the last. This is important in manufacturing environments where consistency is critical for product quality. The use of computer software to plan and optimize the cutting path helps to maintain consistency and reproducibility across multiple parts or production runs. - Greater Design Freedom:

CNC aluminum service provides greater design freedom, allowing for the creation of complex and intricate designs that are not possible with traditional manufacturing methods. This can be particularly useful in industries such as aerospace, medical, and automotive, where parts often have complex geometries and strict specifications. - Improved Quality Control:

CNC aluminum service provides greater control over the manufacturing process, allowing for more precise and accurate parts. This can help improve quality control and reduce defects, leading to higher customer satisfaction and lower costs.

|

|

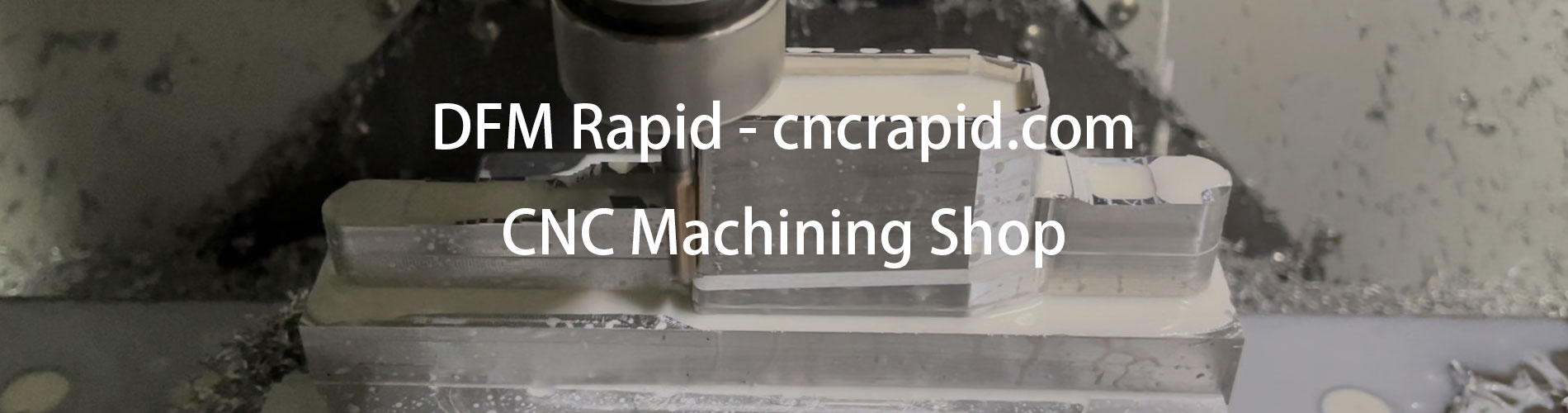

Why Choose DFM Rapid?

At DFM Rapid, we specialize in providing high-quality CNC aluminum service to meet the manufacturing needs of our clients. With years of experience in the industry, we’ve developed a reputation for delivering consistent, precise, and reliable parts that meet the strictest industry standards.

|

|

Our team of experts is dedicated to providing personalized service and support to each of our clients. We work closely with you to understand your specific needs and requirements, and then use our advanced equipment and software to produce parts that meet your exact specifications.

We pride ourselves on our commitment to quality, efficiency, and customer satisfaction. From start to finish, we prioritize clear communication and transparency to ensure that our clients are always informed and satisfied with our work.

Whether you need a small prototype or a large production run, we’re here to help. Our CNC aluminum service offers a range of benefits, from precision and accuracy to cost-effectiveness and time savings. With our expertise and attention to detail, you can trust us to deliver the highest quality parts for your manufacturing needs.

At DFM Rapid, we’re dedicated to providing reliable and efficient CNC aluminum service that meets the needs of our clients. Contact us today to learn more or request a quote for your next project. We look forward to working with you.

Contact us

If you need Metal & Plastic CNC Service parts for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!