CNC machining has revolutionized the manufacturing industry. This manufacturing process, where pre-programmed computer software dictates the movement of machinery and factory tools, has automated three-dimensional cutting tasks in a precise and efficient manner.

At DFM Rapid, also known as CNC Rapid, we offer a variety of services, including CNC Machining Services, CNC Rapid Prototyping, Custom CNC Parts, Aluminum CNC Machining, and CNC Turning Services. In this blog post, we’ll explore the significance of CNC machining in modern manufacturing.

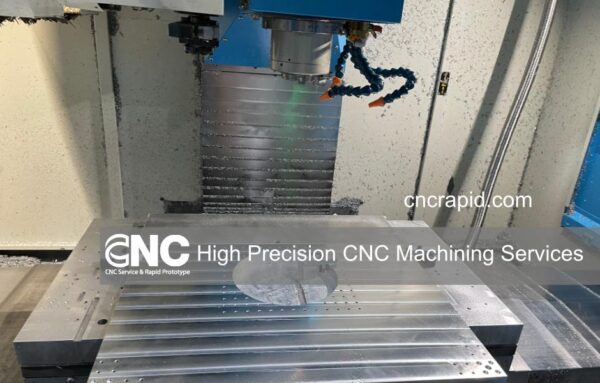

CNC Machining Services: Speed and Efficiency

In today’s fast-paced world, speed and efficiency are the keys to staying competitive, and CNC machining delivers on both fronts. Our CNC Machining Services allow for the rapid production of parts with high precision, significantly reducing the time it takes to bring a product from design to market. Unlike manual machining, CNC machines can operate around the clock with minimal supervision, increasing the productivity of the manufacturing process.

CNC Rapid Prototyping: Bringing Ideas to Life

When it comes to the development of new products, having a physical model can make a significant difference. Our CNC Rapid Prototyping service brings your ideas to life, allowing you to hold, test, and refine your design before moving into full production. This not only saves time and money but also reduces the risk of costly mistakes.

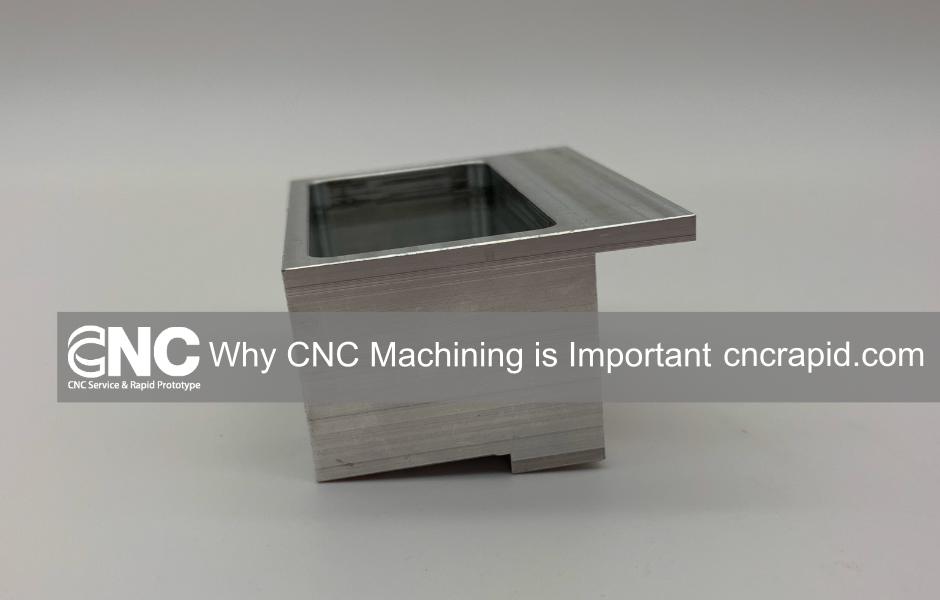

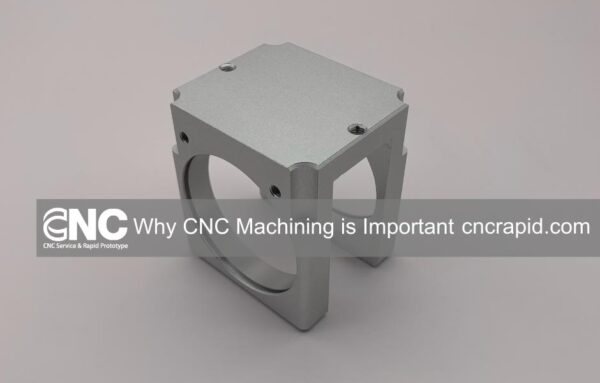

Custom CNC Parts: Precision and Consistency

The level of precision that CNC machining provides is unparalleled, particularly when creating Custom CNC Parts. Each part is produced to exact specifications, ensuring consistency across all products. This is especially important in industries such as aerospace and automotive, where even the slightest error can lead to significant problems.

CNC Turning Services: Versatility and Accuracy

With CNC Turning Services, we can create complex parts with excellent accuracy and finish, making it a preferred choice for many applications. This technique offers a wide range of possibilities for shaping parts, adding to the versatility of CNC machining as a whole.

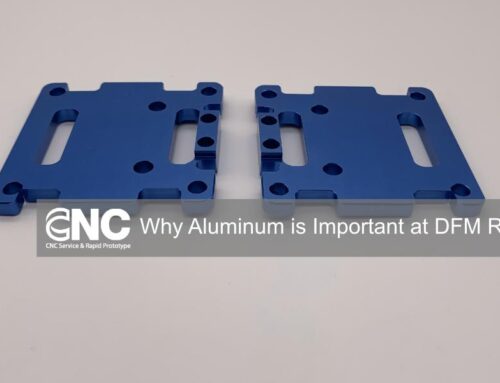

Aluminum CNC Machining: Strength and Durability

CNC machines can work with a wide range of materials, from metals like aluminum and brass to plastics and wood. Our Aluminum CNC Machining service takes advantage of the strength and durability of aluminum, producing parts that are both lightweight and strong. This versatility allows manufacturers to produce parts and prototypes for various industries using the same machinery, saving time and resources.

CNC machining plays a vital role in modern manufacturing. It offers a level of speed, efficiency, and precision that manual machining simply cannot match. As technology continues to evolve, we can expect CNC machining to become even more important, making it an essential tool for any modern manufacturer.

Ready to experience the precision and efficiency of CNC machining? Contact CNC Rapid today for a quote on our CNC Machining Services, CNC Rapid Prototyping, Custom CNC Parts, Aluminum CNC Machining, and CNC Turning Services.

Get a Quote now!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!