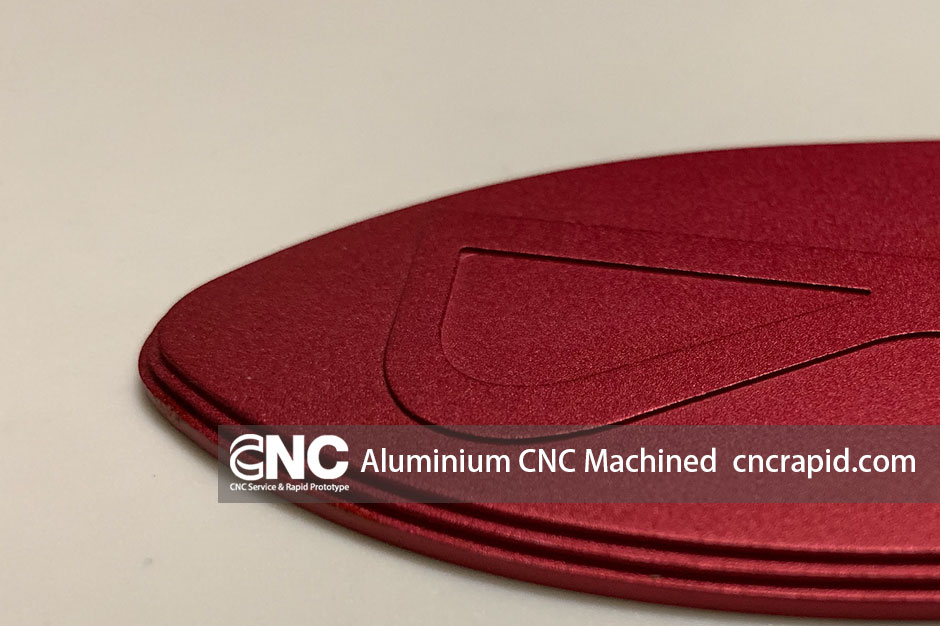

Bead blasted + Anodized type II

Parts are bead blasted and anodized type II. Ideal for increasing the corrosion resistance of the part. The collaborative application of bead blasting and Type II anodizing provides a unique surface treatment approach, combining the advantages of both to achieve a surface that is both aesthetically pleasing and durable on machined parts. Learn more How to Anodize CNC Aluminum Parts.

The “Bead Blasted + Anodized Type II” finish is a testament to the innovative advancements in CNC machining, providing a solution that concurrently addresses aesthetic and functional requisites in machined parts.

Bead Blasting: Engineering Surface Topography

Bead blasting is a surface treatment method that employs high-velocity beads to impact the surface of a part, modifying its topography, and providing a uniform, matte appearance. Notably, in the context of CNC machining, bead blasting is often utilized to conceal tool marks left from the machining process, presenting a clean and consistent surface finish.

The Bead Blasting Process

Step 1: Bead Selection

- Different bead sizes and materials (e.g., glass, ceramic) are chosen based on the desired finish and the material of the workpiece.

Step 2: Blasting Operation

- The beads are propelled against the workpiece using compressed air or mechanical means, impacting the surface and altering its topography.

Step 3: Post-Blasting Cleaning

- The workpiece is thoroughly cleaned to remove any residual beads and debris from the blasting process.

Surface Morphology

- Matte Finish: Bead blasting produces a non-reflective, matte surface, which can be desirable for aesthetic or functional reasons.

- Concealing Tool Marks: The process effectively masks tool marks from CNC machining, providing a uniform surface that can be particularly beneficial for visual parts or those that will be handled frequently.

Material Implications

- Stress Distribution: The blasting process can induce surface stresses that may influence the fatigue performance of the part.

- Surface Hardening: Bead blasting can also result in a certain degree of surface hardening, enhancing wear resistance.

Applications and Considerations

- Aesthetics: Utilized for parts where a consistent, matte appearance is desired, especially for consumer-facing products.

- Functionality: Applied where a uniform surface is critical, such as in parts that interface with seals or where consistent surface properties are necessary.

Anodizing Type II: Electrochemical Fortification

Anodizing Type II, often referred to as regular or sulfuric anodizing, is a widely used electrochemical process that enhances the corrosion resistance, surface hardness, and wear properties of aluminum parts by forming a protective oxide layer. This section delves into the intricate process, layer characteristics, and material considerations of Type II anodizing.

Technical Process of Oxide Formation

Step 1: Pre-Treatment

- Cleaning: Parts are cleaned to remove any contaminants, ensuring a uniform anodizing process.

- Etching: A chemical etch is often used to provide a matte appearance and remove any surface irregularities.

Step 2: Anodizing

- Electrolytic Solution: Parts are submerged in a sulfuric acid electrolyte.

- Electrical Current: A direct current is applied, causing the release of hydrogen at the cathode and oxygen at the surface of the aluminum part, forming an aluminum oxide layer.

- Temperature Control: Maintaining the electrolyte at a lower temperature (typically 32°F – 50°F) is crucial for consistent oxide formation.

Step 3: Post-Anodizing

- Sealing: The porous aluminum oxide layer is sealed to enhance corrosion resistance and dye retention.

Layer Characteristics

- Thickness: Type II anodizing typically produces a coating thickness of 0.0004” – 0.0012”.

- Pore Structure: The oxide layer contains numerous microscopic pores that can absorb dyes or lubricants.

- Barrier Layer: The initial layer formed, known as the barrier layer, has a higher electrical resistance than the outer porous layer.

Material Considerations

- Substrate: The base aluminum alloy influences the final appearance and properties of the anodized layer.

- Dyeing: The porous nature of the anodized layer allows for the absorption of dyes, providing a wide range of color options.

- Wear Resistance: The anodized layer provides enhanced wear resistance, crucial for moving parts or components exposed to frequent handling.

Applications and Limitations

- Applications: Widely used in various sectors, including aerospace, automotive, and consumer electronics, due to its balance of aesthetics and performance.

- Limitations: While it provides enhanced surface properties, Type II anodizing is not suitable for parts that will be exposed to extreme wear conditions or aggressive corrosive environments.

Quality and Compliance

Ensuring the quality and consistency of the anodized layer involves:

- Thickness Testing: Utilizing eddy current techniques or microscopic measurement.

- Seal Quality: Checked through acid dissolution or dye absorption tests.

- Visual Inspection: Ensuring uniformity of color and absence of defects.

In CNC machining, the collaborative application of bead blasting and Type II anodizing provides a unique surface treatment approach, combining the advantages of both to achieve a surface that is both aesthetically pleasing and durable on machined parts.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

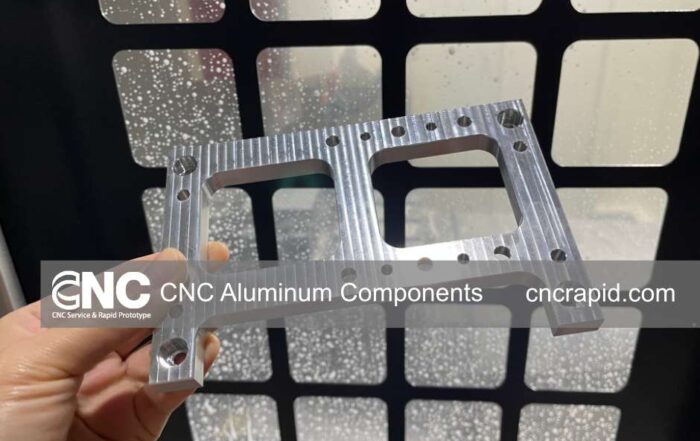

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

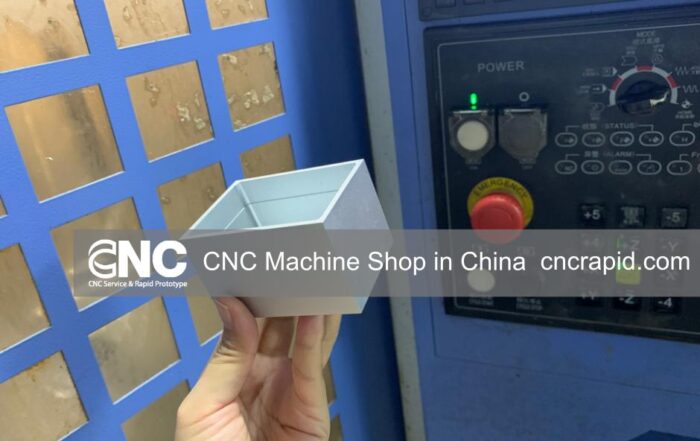

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]