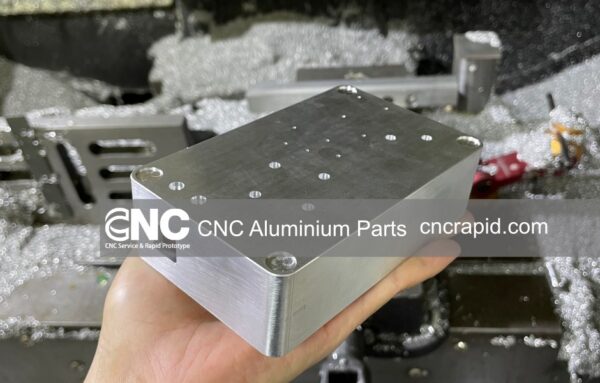

At CNC Rapid, we specialize in high-precision aluminium 2024 CNC machining, offering custom solutions for industries that require durable, lightweight, and high-strength components. Aluminium 2024 is known for its exceptional strength-to-weight ratio and fatigue resistance, making it ideal for applications in aerospace, automotive, and military equipment. With our advanced CNC machining technology, we provide reliable, high-quality aluminium 2024 parts tailored to meet the unique specifications of each client.

Why Choose Aluminium 2024?

Strength and Durability

Aluminium 2024 is one of the strongest aluminium alloys available, making it highly suitable for demanding applications. Its unique composition, primarily of aluminium and copper, provides excellent strength, even under significant stress. This alloy is well-regarded for its resistance to fatigue, which makes it an excellent choice for components that undergo constant mechanical stress and require long-lasting durability.

Lightweight Properties

In addition to its strength, aluminium 2024 is also exceptionally lightweight. This quality makes it highly sought after in industries like aerospace and automotive, where reducing weight without compromising on strength is essential. Components machined from aluminium 2024 contribute to overall system efficiency by reducing fuel consumption and improving performance.

Good Machinability

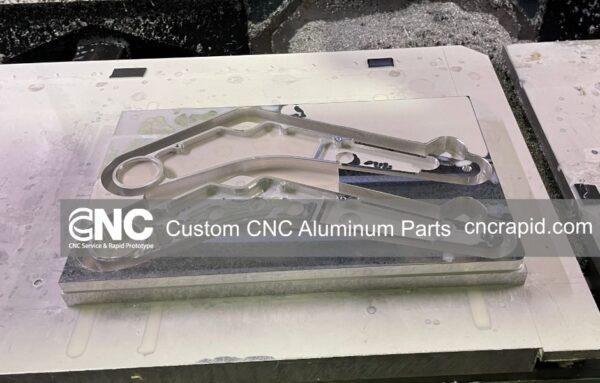

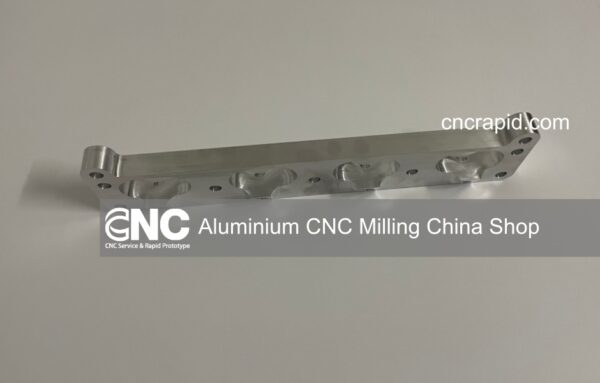

Aluminium 2024 is known for its good machinability, allowing for efficient and precise CNC machining. This alloy responds well to cutting, milling, and drilling, making it possible to produce complex geometries with tight tolerances. At CNC Rapid, we leverage these properties to provide fast turnaround times and cost-effective solutions for clients who require custom aluminium 2024 parts.

CNC Machining Capabilities for Aluminium 2024

Precision and Accuracy

Our CNC machining facilities are equipped to handle the precise requirements of aluminium 2024. With multi-axis CNC machines and skilled machinists, CNC Rapid can produce parts with intricate details and complex shapes, meeting tight tolerances and maintaining consistent quality. Our precision CNC machining capabilities allow us to create components that meet the strictest industry standards, ensuring reliable performance and durability.

Versatile Applications

Aluminium 2024’s high strength and lightweight nature make it an ideal choice for components in several industries:

- Aerospace: Lightweight, high-strength components for airframes, wings, and structural parts.

- Automotive: High-performance parts for engines, chassis, and suspension systems.

- Military and Defense: Rugged, durable components used in tactical equipment and transport vehicles.

- Industrial Machinery: Custom fittings and mounts for machines where durability is a priority.

Custom CNC Machining Solutions

At CNC Rapid, we understand that each project is unique, and we work closely with our clients to deliver custom CNC machining solutions tailored to their needs. Our team of experienced engineers and machinists collaborate on each project to ensure that every aluminium 2024 component is manufactured to the exact specifications required for optimal performance. Whether you need a prototype or full production run, we can scale our services to meet your demands.

Surface Finishing Options

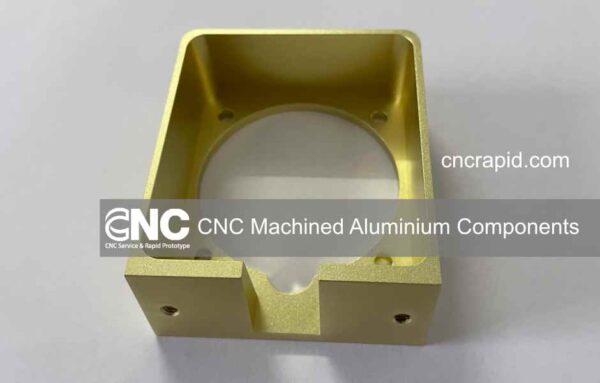

To enhance the functionality and appearance of aluminium 2024 parts, CNC Rapid offers a variety of surface finishing options:

- Anodizing: Provides a protective oxide layer that enhances corrosion resistance and adds an aesthetic finish. Anodizing also allows for color customization, giving components a professional appearance.

- Polishing: Creates a smooth, reflective surface ideal for parts that require a sleek, finished look.

- Bead Blasting: Gives a matte texture, ideal for components that need a non-reflective surface.

- Powder Coating: Adds an additional layer of protection, further improving the component’s resistance to corrosion, wear, and impact.

These finishing options not only improve the component’s durability but also enhance its appearance, making it suitable for high-visibility applications.

Quality Assurance at CNC Rapid

At CNC Rapid, we are committed to delivering parts of the highest quality. Each aluminium 2024 component we produce undergoes rigorous quality control checks to ensure that it meets the specified tolerances, dimensions, and surface finish. Our quality assurance team uses advanced inspection equipment, such as coordinate measuring machines (CMM), to verify every part’s accuracy and precision.

Our dedication to quality ensures that each part performs as expected, whether it is used in high-performance engines, aircraft, or industrial machinery. This commitment to excellence has made CNC Rapid a trusted provider of CNC machining services for clients across various industries.

Why Choose CNC Rapid for Aluminium 2024 CNC Machining?

Advanced CNC Technology

Our advanced CNC machines allow us to produce high-precision parts efficiently, making CNC Rapid a reliable partner for complex projects. From multi-axis machining to complex milling and drilling, we have the capabilities needed to handle the requirements of aluminium 2024 machining.

Experienced Team

Our team of skilled engineers and machinists brings years of expertise to each project, ensuring that every component is manufactured to exact specifications. We work closely with our clients throughout the process, offering technical support and guidance to achieve the best possible outcomes.

|

|

Fast Turnaround Times

With streamlined processes and efficient production, CNC Rapid offers fast turnaround times, helping clients meet tight deadlines without compromising quality. Whether you need prototypes or production parts, we are equipped to deliver on time.

Contact CNC Rapid Today!

For top-quality aluminium 2024 CNC machining services, contact CNC Rapid today. Our team of experts is ready to assist you with custom machining solutions that meet your exact requirements. Reach out to us for a consultation or to request a quote, and experience the precision and excellence of CNC Rapid’s aluminium machining capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!