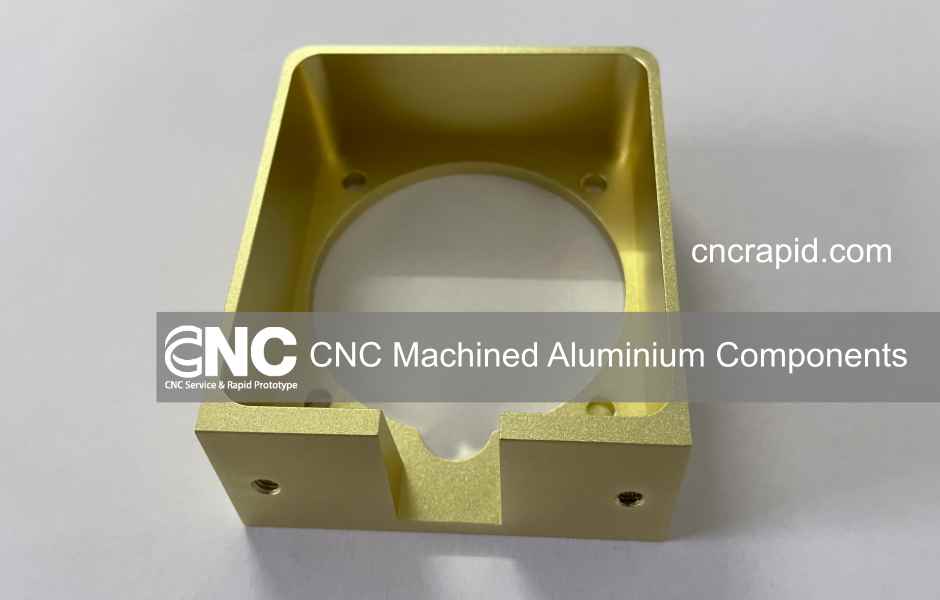

CNC Machined Aluminium Components. We provide innovative solutions to a diverse line of industries. Our engineers are experts in CNC machining custom parts. We have a lot of experience with custom CNC aluminum parts projects, whether you’re looking to make prototypes or small batches manufacturing, we can help.

CNC Machining

CNC machines can produce precision parts without operator assistance. Once programmed with the necessary design parameters, internal computers direct the equipment’s machine head and tools in creating parts. This enables fast, reliable production with exceptional precision and piece-to-piece repeatability. With non-stop manufacturing capabilities, CNC machining saves time in the production process, and the reduction in waste and improved accuracy of manual machining save money and materials.

CNC Machined Aluminium Components

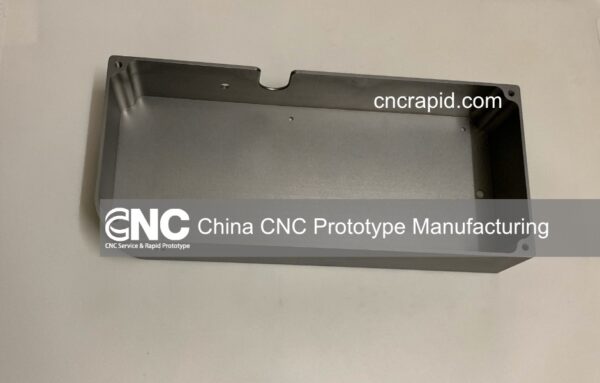

We offer CNC machining services for most metals and other materials, including stainless steel, plastic and aluminum parts. We have extensive experience in precision CNC machining, and utilize cutting-edge equipment, including precision CNC machines and CNC lathes, to deliver custom machined parts that meet our customers’ exact specifications.

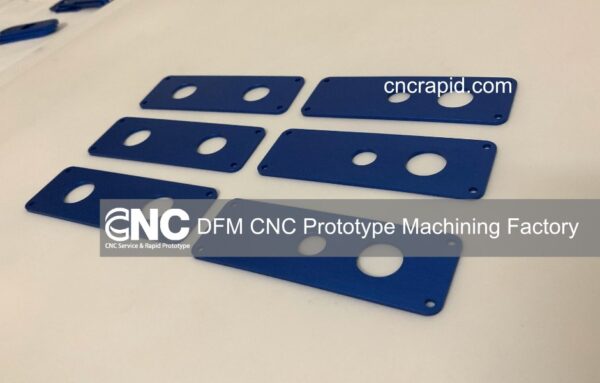

CNC Parts Manufacturing

For custom prototype cnc or high-volume production runs of metal, plastic and aluminum parts, we deliver metal machining. Request a quote for the custom CNC machining your project requires, or contact us for more information.

CNC machining for rapid prototyping allows you to leverage the many advantages of computerized equipment to produce fast-turnaround prototypes, engineering models and high-quality end-use parts in the least possible time.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Advantages Of CNC Machining

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

- Quick removal of large amounts of metal material

- Highly accurate and repeatable

- Suitable for many different kinds of substrates

- Scalable volumes from one to 100,000

- Low investment in tooling and preparation costs

- Economical

- Fast turnaround

Get in Touch

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!