Key Advantages of Choosing 303 Stainless Steel for CNC Machining

The selection of 303 stainless steel for CNC machining is attributed to its exceptional machinability and sturdiness, which facilitates efficient production and durability in products. Moreover, its attributes such as resistance to oxidation, heat, and atmospheric corrosion further enhance its attractiveness as an ideal material for various manufacturing sectors.

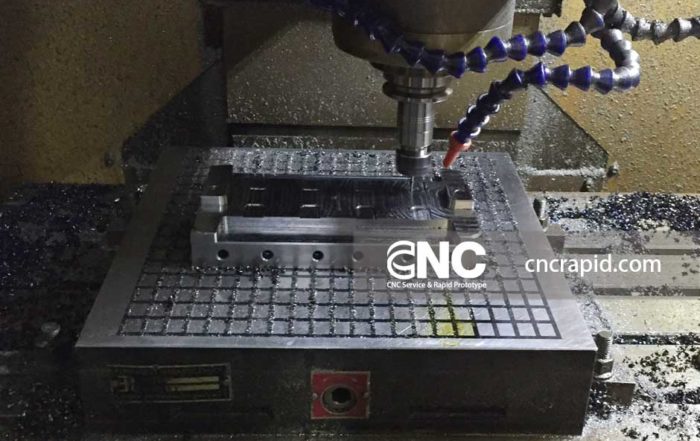

CNC machining materials offer an array of options, among which 303 stainless steel holds a unique position. Renowned for its outstanding machinability complemented by the sturdiness of stainless steel, this alloy has become a favorite among product design engineers. This article provides a deep exploration into the properties, advantages, and uses of 303 stainless steel in CNC machining.

Chemical Composition: 303 stainless steel is an austenitic, free-machining stainless steel. The addition of sulfur enhances its machinability, making it distinct from other stainless steel grades. Its primary elements include:

- Chromium: 17-19%

- Nickel: 8-10%

- Carbon: 0.15% max

- Manganese: 2% max

- Silicon: 1% max

- Sulfur: 0.15% min

Mechanical Properties:

- Tensile Strength: 620 MPa

- Yield Strength: 310 MPa

- Elongation: 50%

- Hardness: 202 Brinell

Corrosion Resistance: While 303 stainless steel offers good resistance to oxidation and corrosion, it’s slightly less resistant than its counterpart, 304 stainless steel, due to the addition of sulfur. However, with proper care and maintenance, it can serve well in environments prone to mild corrosive elements.

Machinability: The sulfur addition in 303 stainless steel is a game-changer. It drastically improves chip breaking, reduces tool drag, and enhances overall machinability. This makes 303 an ideal choice for intricate and detailed CNC machining tasks where precision is paramount.

Applications in CNC Machining:

- Precision Parts: Its ability to achieve tight tolerances makes it perfect for components requiring exact measurements.

- Gears and Bearings: Its wear resistance ensures longevity in moving parts.

- Custom Fasteners: For applications where strength needs to meet aesthetics.

Surface Treatments and Weldability: 303 stainless steel can be polished to a high shine, making it suitable for visible components. However, its sulfur content makes it less weldable than other grades. If welding is essential, it’s recommended to use 308L filler metal.

Design Insights: When designing for 303 stainless steel, it’s crucial to consider its machinability advantages. Utilize its ability to achieve tight tolerances and intricate details. However, be cautious about welding, and if possible, design parts to avoid it or use alternative joining methods.

303 stainless steel is a testament to the balance between machinability and durability. Its unique composition makes it a favorite in the CNC machining world, offering engineers and designers a material that doesn’t compromise on precision or strength.

To explore the full potential of 303 stainless steel for your next CNC machining project, or to discuss specific design challenges, connect with our team. We’re dedicated to ensuring your visions are realized with unmatched precision.

Comparison between 303 and 304 Stainless Steel

| Property/Characteristic | 303 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Main Alloying Elements | Chromium: 17-19%, Nickel: 8-10%, Sulfur: 0.15% min | Chromium: 18-20%, Nickel: 8-10.5% |

| Machinability | Excellent due to added sulfur | Good, but not as machinable as 303 |

| Corrosion Resistance |

Good, but slightly less than 304 due to sulfur content | Excellent, especially in oxidizing environments |

| Weldability | Fair; not as weldable as 304 due to sulfur content | Excellent; can be welded using most standard methods |

| Common Applications | Precision components, gears, bearings, custom fasteners | Food and beverage equipment, construction materials, automotive components, medical equipment |

| Cost | Typically slightly less expensive than 304 | Generally more expensive due to its higher nickel content and better corrosion resistance |

| Finish | Can be polished, but not as shiny as 304 | Can achieve a mirror finish with polishing |

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

Precision 304 Stainless Steel Fixture Blocks by CNC Rapid

At CNC Rapid, we understand that every component in the machining process plays a critical role. One such component—the 304 stainless steel fixture blocks, has become indispensable in ensuring consistent, high-quality results in CNC machining. [...]

Online CNC Quote: How to Ensure Quality and Affordability

In today's fast-paced manufacturing world, finding a CNC service that offers both quality and affordability can be tough. At CNC Rapid, we've simplified this process for you. Understanding CNC Machining:CNC machining is a subtractive manufacturing [...]

Stainless steel CNC machining services China

Stainless steel CNC machining services China. We specialize in production machining services, engineering and using the latest technology to keep your prices low, without affecting quality. Throughout the years we have added materials to our list [...]

China Stainless Steel CNC Machining Shop

China Stainless Steel CNC Machining Shop. DFM Rapid’s CNC machining services offer you a one-stop CNC rapid prototyping and low-volume manufacturing solution. We have a full suite of CNC equipment to provide multi-axis milling and [...]

Stainless Steel Turned Parts China

Stainless Steel Turned Parts China. We are a CNC Machining Shop in China. CNC Machining part generally refers to piece-parts, or component parts which are custom machined to a customer’s specific requirements. If you need [...]

Stainless Steel Turned Parts Shop

Stainless Steel Turned Parts Shop. Stainless steel is an alloy of iron that is resistant to rusting and corrosion. Stainless steel is used for industrial equipment when it is important that the equipment lasts and [...]