Bead Blasted + Anodized Type III

The combination of bead blasting and Type III anodizing as a comprehensive surface treatment for CNC machined parts offers a potent solution to meet the demanding requirements of various industries.

In the competitive landscape of CNC machining, the surface treatment of machined parts plays a pivotal role in enhancing both aesthetic and functional attributes. A synergistic approach that has gained traction for its efficacy in delivering durability while maintaining a refined appearance is the combination of Bead Blasting and Type III Anodizing. This article delves into the intricacies of this dual surface treatment, exploring its processes, benefits, and applications.

Bead Blasting: Achieving a Uniform Matte Finish

Bead blasting is a surface treatment technique that employs the use of high-velocity beads to impact the surface of a part, effectively removing material residues and concealing tool marks from the CNC machining process, thereby providing a uniform, matte appearance.

- Process: Involves propelling bead particles onto the part’s surface, altering its topography and masking machining marks.

- Aesthetics: Delivers a consistent, non-reflective surface, often desired for visual components.

- Preparation: Serves as an effective pre-treatment method before further surface treatments, such as anodizing, ensuring a clean and consistent substrate.

Type III Anodizing: A Deep Dive into Enhanced Durability and Wear Resistance

Type III Anodizing, commonly referred to as hardcoat anodizing, stands out in the realm of surface treatments due to its exceptional wear resistance and surface hardness. This electrochemical process, while somewhat similar to Type II anodizing, is distinguished by its ability to produce a thicker and denser oxide layer, thereby significantly enhancing the mechanical properties of the treated parts.

The Technical Process of Type III Anodizing

Step 1: Pre-Treatment

- Cleaning: Rigorous cleaning of the aluminum part to remove any contaminants or residues.

- Etching: A light etch is applied to achieve a specific finish and to prepare the surface for anodizing.

Step 2: Anodizing

- Electrolytic Solution: The part is submerged in a chilled sulfuric acid bath.

- Electrical Current: A higher current density than Type II is applied, typically at 24-36 ASF (Ampere per Square Foot).

- Temperature Control: The bath is maintained at a lower temperature, usually between 32°F and 50°F, to facilitate the formation of a denser oxide layer.

- Duration: The process is conducted for a longer period to achieve a thicker oxide layer, often between 60-100 microns.

Step 3: Post-Anodizing

- Sealing: Unlike Type II, Type III anodizing may or may not be sealed to retain its wear-resistant properties.

Characteristics of the Type III Anodized Layer

- Thickness: Achieves a substantially thicker oxide layer, often between 50-100 microns.

- Hardness: Attains a higher surface hardness, reaching up to 60 on the Rockwell C scale.

- Wear Resistance: Exhibits superior wear resistance, making it suitable for parts exposed to high-wear conditions.

- Corrosion Resistance: Offers enhanced corrosion resistance, especially when sealed.

Material and Design Considerations

- Alloy Selection: Different aluminum alloys will yield varying results in hardness and appearance after Type III anodizing.

- Racking Considerations: Thoughtful racking design is crucial to ensure uniform current distribution and consistent anodizing results.

- Dimensional Tolerance: The added thickness from the anodizing layer must be considered in the part’s final dimensions.

Applications of Type III Anodizing

- Industrial Machinery: For components that require high wear resistance.

- Aerospace: Utilized in parts that must withstand harsh conditions while maintaining lightweight characteristics.

- Military and Defense: For equipment that demands durability and reliability in various environments.

Challenges and Solutions

- Uniformity: Achieving a uniform thickness and appearance can be challenging, especially in complex geometries. Strategic fixture design and process control are vital.

- Color Limitations: Type III anodized parts have limited coloration options, typically restricted to darker shades due to the thickness of the oxide layer.

Integrating Techniques: “Bead Blasted + Anodized Type III”

Combining bead blasting with Type III anodizing brings forth a surface that is not only visually appealing but also remarkably robust.

- Sequential Process: Initially, parts undergo bead blasting to achieve a matte, uniform surface, followed by Type III anodizing to enhance its wear and corrosion resistance.

- Balanced Attributes: This combination ensures that the parts exhibit a balance between aesthetic appeal (achieved through bead blasting) and enhanced mechanical properties (imparted by Type III anodizing).

- Versatility: Suitable for a myriad of applications where both visual appeal and durability are paramount.

Applications and Implications

- Aerospace & Automotive: Ideal for components that require a balance of lightweight, durability, and aesthetic appeal.

- Consumer Electronics: Utilized in devices that demand a sleek appearance while ensuring longevity and resistance to wear.

- Medical Devices: Applied in instruments that require reliability, cleanliness, and visual consistency.

Challenges and Mitigations

- Process Control: Ensuring consistency in both bead blasting and anodizing processes to maintain uniformity in appearance and properties.

- Cost Implications: Balancing the cost-effectiveness with the benefits imparted by the dual treatment.

- Environmental Considerations: Adhering to environmental regulations and adopting eco-friendly practices in the treatment processes.

Anodized Type II Vs. Anodized Type III in CNC Aluminum Parts

Anodizing stands out as a pivotal surface treatment, especially pertinent to aluminum parts, by enhancing their corrosion and wear resistance while also providing superior adhesion for paint primers and glues. The decision between utilizing Type II and Type III anodizing can markedly influence the final attributes and application suitability of the machined part.

Comparative Analysis

- Thickness and Durability: Type III anodizing, often referred to as “hard anodizing,” typically produces a thicker oxide layer compared to Type II, resulting in enhanced wear and corrosion resistance.

- Aesthetic Versatility: Type II anodizing offers a wider array of color options and tends to provide a more aesthetically glossy finish, making it a preferred choice for consumer-facing products.

- Application Suitability: While Type II might be favored for applications requiring aesthetic versatility, Type III is often chosen for industrial applications where enhanced durability is paramount.

- Cost Implications: Type III anodizing generally comes with a higher cost due to the increased energy, longer processing times, and additional wear on the anodizing equipment due to the aggressive process conditions.

| Attribute | Anodized Type II | Anodized Type III |

|---|---|---|

| Thickness | 0.8 to 25 microns | 13 to 150 microns |

| Hardness | Moderate | High |

| Wear Resistance |

Moderate | High |

| Corrosion Resistance | Good | Excellent |

| Color Options | Wide Range | Limited, mostly darker shades |

| Finish | Can be glossy | Typically matte and non-reflective |

| Cost |

Generally lower | Generally higher |

| Typical Applications | Consumer products, decorative items | Industrial components, high-wear parts |

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

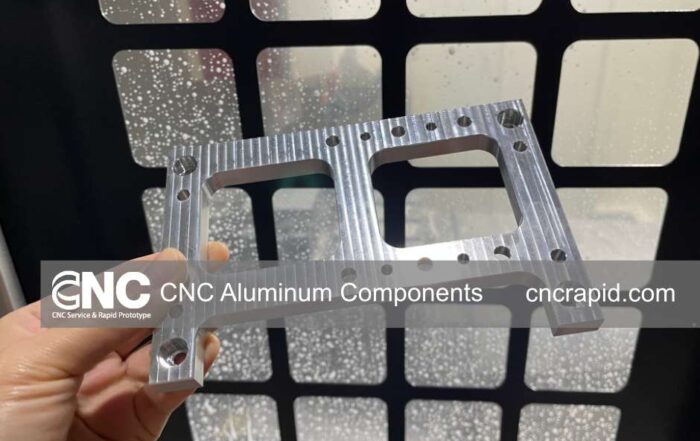

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

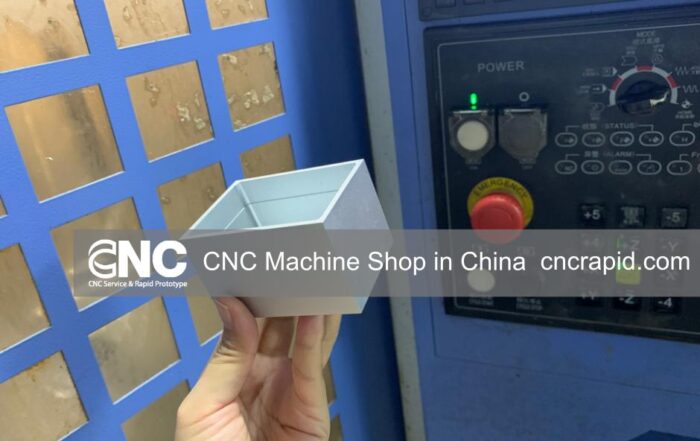

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]