Smooth machining (Ra 1.6μm / Ra 63μin)

Smooth machining is like an ‘As machined’ finish but with slightly less evident machine marks. Parts are machined at a lower feed, no hand polishing is applied.

Surface finishes, especially in CNC machining, are paramount in dictating the performance, wear resistance, and aesthetic appeal of manufactured parts. ‘Smooth machining (Ra 1.6μm / Ra 63μin)’ denotes a surface finish that is not only visually appealing but also functionally significant in various applications.

Achieving a smooth machined surface, particularly with an Ra of 1.6μm / 63μin, demands meticulous planning, precise tooling, and optimized machining parameters. This surface finish is often sought in applications where reduced friction, enhanced wear resistance, or premium aesthetics are paramount.

Exploring various applications where ‘Smooth machining (Ra 1.6μm / Ra 63μin)’ is pivotal, such as in aerospace components, medical devices, or high-end consumer products, and discussing the considerations and challenges in achieving this surface finish.

As machined Vs. Smooth machining

| Aspect | As machined (Ra 3.2μm / Ra 126μin) | Smooth machining (Ra 1.6μm / Ra 63μin) |

|---|---|---|

| Appearance | Likely rougher, visible tool marks | Smooth, minimal visible tool marks |

| Applications | Suitable where surface finish is not critical | Essential where low friction or aesthetic is vital |

| Cost |

Generally lower due to fewer machining steps | Might be higher due to additional processes |

| Production Time | Typically faster with fewer processes | Maybe longer due to additional finishing steps |

| Material Wear | Potentially higher, depending on application | Generally lower due to smoother surface |

| Aesthetic Appeal | May be considered industrial or rugged | Often considered premium or high-end |

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

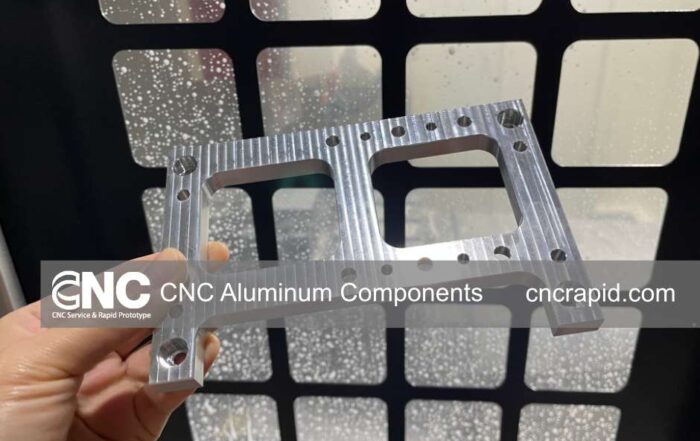

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

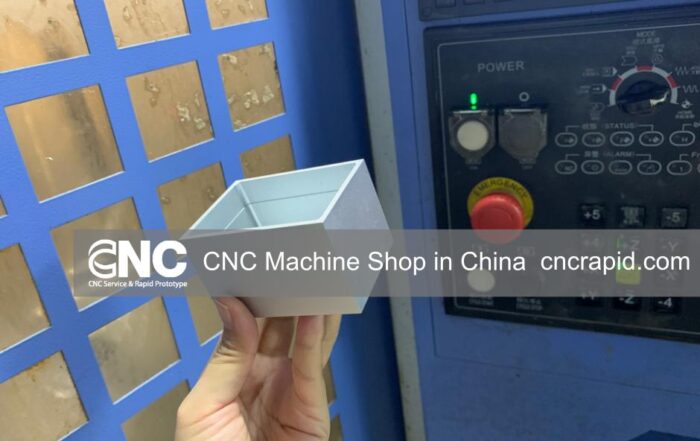

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]