The Significance of Polypropylene in CNC Machining:

Polypropylene, with its multifaceted properties and adaptability, continues to be a material of choice in CNC machining, bridging the gap between design, functionality, and sustainability. Its versatility in applications from the medical field to the automotive industry underscores its relevance and indispensability in modern manufacturing.

Polypropylene (PP), renowned for its balance of properties, has carved its niche in the realm of CNC machining. Its unique blend of physical and chemical characteristics not only makes it a favorite among materials but also a viable option for various applications across diverse industries.

The Allure of Polypropylene

Polypropylene stands out due to its lightweight, high tensile strength, and remarkable resistance to chemicals, electricity, and fatigue. Its low density does not compromise its toughness and resistance to wear and tear, making it an excellent material for CNC machining processes where precision and durability are paramount.

Machining Polypropylene: A Closer Look

Machining PP involves considerations like choosing the right tools, optimizing speeds and feeds, and ensuring optimal cooling to prevent deformation. PP’s low coefficient of friction and inherent lubricity mean less wear on tools and a smoother machining process, but its low melting point demands a keen eye on temperature management during machining.

Polypropylene in Action: Diverse Applications

- Medical Industry: PP’s resistance to chemicals and ability to be sterilized make it a staple for medical components like surgical instruments and containers.

- Automotive Sector: With its high strength-to-weight ratio, PP is utilized for making interior components, under-the-hood parts, and bumper systems.

- Packaging: The chemical resistance and durability of PP make it a preferred choice for containers, packaging materials, and labeling.

Designing with Polypropylene: Best Practices

When designing for CNC machining with PP, considerations like wall thickness, radii, and transitions are crucial to ensure structural integrity while avoiding issues like warping during machining. It’s also vital to account for PP’s thermal properties to prevent design flaws that could arise from its low melting point.

Sustainability and Polypropylene

PP aligns with sustainability goals due to its recyclability. Its ability to be reprocessed without significant degradation of properties means it can be reused in manufacturing, contributing to a circular economy and reducing waste in production cycles.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

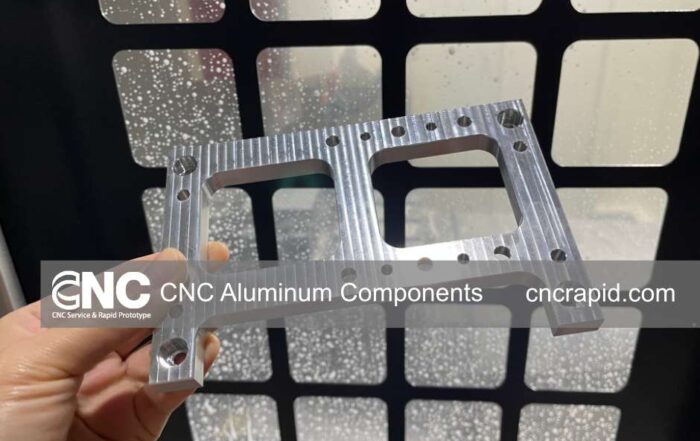

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

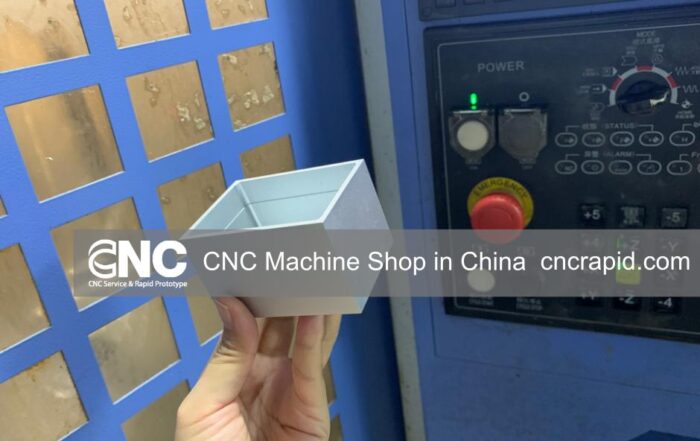

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]