The Significance of Mild Steel 1045 in CNC Machining:

Mild Steel 1045 stands out as a material of choice in CNC machining, offering a blend of machinability, strength, and hardness. Its wide-ranging applications across various industries attest to its versatility and reliability. By choosing Mild Steel 1045, manufacturers and engineers are not only ensuring the production of high-quality components but also adhering to sustainable manufacturing practices.

Mild Steel 1045 is a medium carbon steel known for its impressive strength, hardness, and machinability, making it a preferred material in various industrial applications, including CNC machining. This article delves into the characteristics, applications, and advantages of employing Mild Steel 1045 in CNC machining endeavors.

Characteristics of Mild Steel 1045

- Strength and Hardness: 1045 steel offers a good balance of strength and hardness, providing structural integrity to machined parts.

- Machinability: Its excellent machinability allows for efficient and precise machining processes, reducing wear on tools.

- Weldability: While it’s weldable, preheating and post-welding heat treatment are often recommended to prevent cracking.

- Heat Treatment: Capable of being heat treated to enhance its mechanical properties like hardness and strength.

CNC Machining and Mild Steel 1045

Mild Steel 1045’s machinability and strength make it a popular choice in CNC machining, facilitating the creation of durable and precise components with ease. Its ability to undergo heat treatment allows for additional enhancement of mechanical properties post-machining, ensuring the production of robust parts.

Applications Across Diverse Industries

- Automotive: Utilized in producing gears, shafts, and other critical components due to its strength and hardness.

- Manufacturing: Employed in creating jigs, fixtures, and machine parts owing to its machinability and durability.

- Construction: Used in structural applications where strength and durability are paramount.

Designing with Mild Steel 1045

When designing components with Mild Steel 1045, considering its mechanical properties and heat treatment capabilities is vital. Ensuring that the design is optimized for its strength, hardness, and machinability will result in components that are not only accurate but also durable and reliable.

Sustainability and Recycling

Mild Steel 1045 aligns with sustainable manufacturing practices due to its recyclability. The material can be melted down and reformed into new products, reducing waste and promoting environmentally responsible manufacturing.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

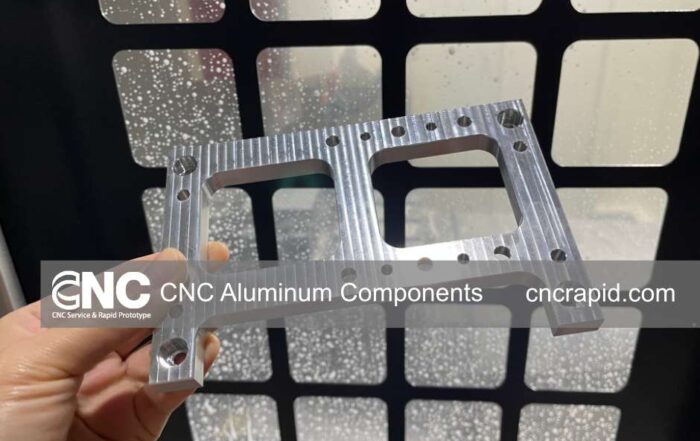

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

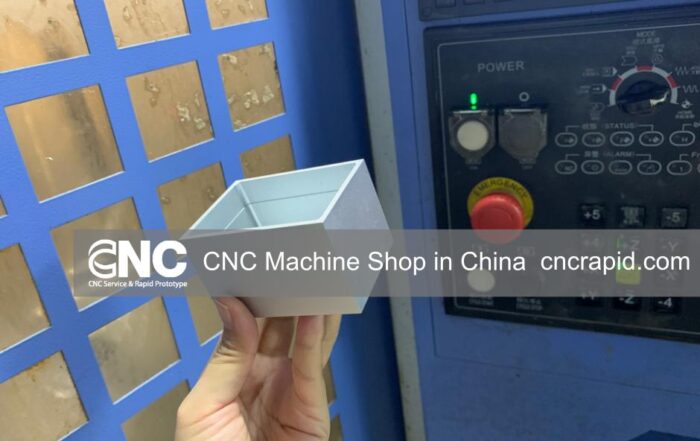

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]