Black Chrome Plating

Suitable for various substrates, black chrome plating is an electrochemical process utilized to enhance wear resistance and reduce light reflection, while also providing a sleek, professional aesthetic appeal to the parts.

Black chrome plating stands out as a distinguished surface treatment method, offering a blend of visual appeal and enhanced physical properties. This technique, characterized by its unique black sheen and superior attributes, finds its place across a myriad of industries, becoming a go-to solution for various applications. This exploration into black chrome plating will illuminate its process, benefits, and utilization in different contexts.

The Art and Science of Black Chrome Plating

Black chrome plating is an electrochemical process that enhances the physical and chemical properties of a substrate by depositing a layer of black chrome onto it. This unique black coating not only provides a visually appealing aspect but also enhances the part’s corrosion resistance, hardness, and wear resistance.

The Process of Black Chrome Plating

- Pre-treatment: Ensuring the part surface is clean, smooth, and free of greases.

- Plating: Depositing black chrome onto the substrate through electrical current.

- Post-treatment: May include additional coatings or heat treatments to enhance the performance of the plated layer.

Advantages of Black Chrome Plating

- Wear Resistance: Offers superior wear resistance, suitable for high-friction applications.

- Corrosion Resistance: Enhances the ability of the part to resist corrosion, extending its lifespan.

- Aesthetics: Provides a high-quality and professional appearance.

Applications of Black Chrome Plating in CNC Parts

- Automotive Parts: For enhancing the wear resistance and appearance of parts.

- Precision Instruments: To provide additional corrosion protection and reduce light reflection.

- Industrial Equipment: To improve the durability of equipment and reduce maintenance needs.

Challenges and Solutions

While black chrome plating offers a range of advantages, it also presents challenges such as costs and environmental impacts. Choosing the right supplier and ensuring compliant waste management is crucial.

Black chrome plating attracts manufacturers and engineers across various applications with its superior wear resistance, corrosion resistance, and aesthetics. By understanding its process and advantages in depth, we can utilize this surface treatment technology wisely to meet the demands and challenges of specific applications.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

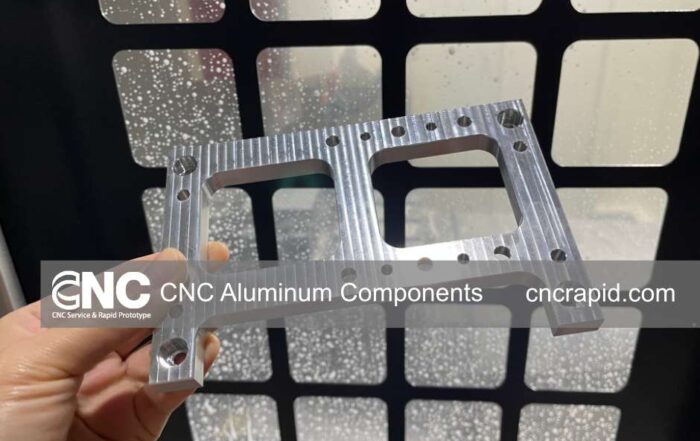

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

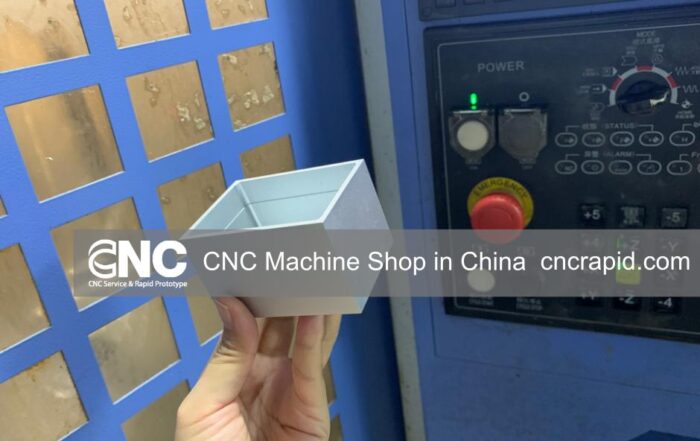

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]