The Significance of 6063 Aluminum in CNC Machining:

In CNC machining, 6063 aluminum alloy is highly valued for its exceptional extrudability and superior anodizing capabilities, making it a preferred choice for intricate designs requiring both aesthetic appeal and functional precision. Its unique blend of machinability and surface finish options positions it as an indispensable material for engineers and designers aiming for top-tier results.

Among the myriad of materials available for CNC machining, the 6063 aluminum alloy stands out distinctly. Celebrated for its excellent extrusion capabilities and unparalleled suitability for anodizing, this alloy is a top-tier choice for engineers and designers aiming for both aesthetics and functionality.

Chemical Composition of 6063 Aluminum Alloy:

- Primary Element: Aluminum

- Alloying Elements:(Silicon: 0.2% – 0.6%, Iron: Up to 0.35%, Copper: Up to 0.10%, Manganese: Up to 0.10%, Magnesium: 0.45% – 0.9%, Chromium: Up to 0.10%, Zinc: Up to 0.10%, Titanium: Up to 0.10%)

Physical and Mechanical Properties:

- Density: 2.68 g/cm³

- Melting Point: Approximately 615°C

- Tensile Strength: 186 MPa

- Yield Strength: 145 MPa

- Elongation: 12%

Corrosion Resistance: 6063 aluminum alloy offers good corrosion resistance, making it suitable for outdoor applications and environments where it may be exposed to moisture and chemicals.

Machinability: 6063 is known for its good machinability, allowing for smooth and efficient operations when using standard machining techniques. Its softness ensures minimal tool wear.

Anodizing Excellence:

- Why 6063 is Ideal for Anodizing: Its fine grain structure allows for a superior, consistent finish post-anodizing.

- Types of Anodizing Suitable for 6063: From Type II (sulfuric acid anodizing) to Type III (hard anodizing).

- Design Considerations for Anodizing: Ensuring uniformity, understanding color variations, and achieving desired aesthetics.

Applications in CNC Machining:

- Architectural and Structural Profiles: Window frames, door frames, and curtain walls.

- Heat Sinks: Given its excellent thermal conductivity.

- Furniture: Chair frames, table legs, and other decorative elements.

- Piping and Tubing: For both structural and fluid transfer purposes.

Design Insights for Engineers:

- Formability: 6063 can be easily formed into complex shapes, making it ideal for custom designs.

- Joining Techniques: Suitable for welding, brazing, and soldering.

- Surface Treatment Options: Beyond anodizing, 6063 can be painted, powder-coated, or left in its natural state for a variety of finishes.

The 6063 aluminum alloy is more than just a material; it’s a versatile solution that offers engineers and designers a unique blend of design flexibility, aesthetic appeal, and functional prowess. Its exceptional anodizing capabilities further cement its position as a go-to choice in the CNC machining world.

To delve deeper into the potential of the 6063 aluminum alloy for your next project or to discuss specific machining challenges, connect with our team of experts. We’re here to guide, assist, and ensure your visions come to life with precision and flair

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

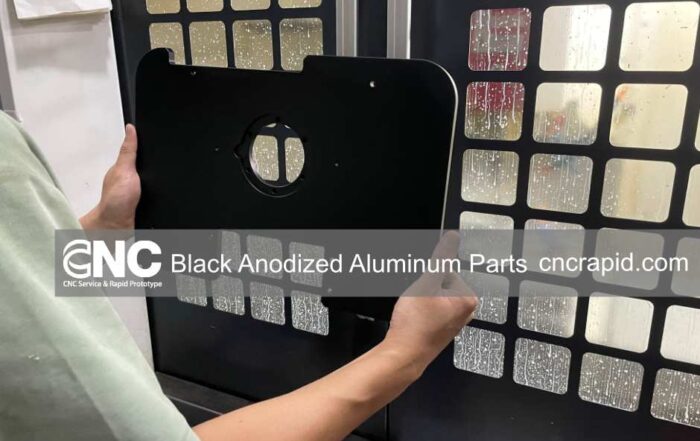

CNC Rapid Black Anodized Aluminum Enclosures

Black Anodized Aluminum Enclosures instantly signal quality when you pick up a well-built device. Their deep-black, satin surface feels solid yet light, resists fingerprints, and quietly guides heat away from sensitive components. Achieving that effect [...]

Clear Anodized Aluminum CNC Precision Machined Components

The easiest way to keep aluminum parts looking fresh while holding micron‑level tolerances is to combine modern 3‑ and 5‑axis machining with clear anodizing aluminum. By growing a thin, transparent oxide layer—not paint—you create clear [...]

Black and Natural Anodized Aluminum CNC Parts by CNC Rapid

At CNC Rapid, we specialize in precision CNC machining and professional surface finishing services for custom aluminum parts. One of the most popular finishing methods is anodizing, a process that improves the durability, corrosion resistance, [...]

Precision CNC Lathe Parts with Gold Anodized Finish

At CNC Rapid, we specialize in producing high-precision CNC lathe parts tailored to meet your exact specifications. Today, we're showcasing a custom aluminum part finished with a stunning gold anodized coating — a perfect combination [...]

Custom Aluminum 6063 Keyboard Enclosure by CNC Rapid

As 2025 approaches, the demand for high-quality, customizable keyboard enclosures continues to rise. Whether you’re a gaming enthusiast, a professional typist, or an OEM manufacturer, finding the right balance between durability, aesthetics, and functionality is [...]

Black Anodized Custom Aluminum CNC Machining Services

At CNC Rapid, we specialize in providing black anodized custom aluminum CNC machining services, delivering high-quality, durable, and aesthetically pleasing components for a wide range of industries. With our advanced CNC machining technology and expert [...]