The Significance of Delrin in CNC Machining:

Delrin remains a material of choice for CNC machining, offering a blend of mechanical strength, precision, and chemical resistance. Its wide-ranging applications from the automotive to the medical field testify to its versatility and reliability in producing high-performance parts.

Delrin, also known as Polyoxymethylene (POM), is a thermoplastic renowned for its high stiffness, low friction, and excellent dimensional stability, making it a preferred choice in CNC machining. This article will delve into the properties, machining considerations, and applications of Delrin in various industries.

Key Properties of Delrin

- Mechanical Strength: Delrin offers high tensile strength, stiffness, and resilience, making it suitable for rigorous applications.

- Wear Resistance: Its low friction and wear resistance make it ideal for creating parts where minimal resistance is crucial.

- Chemical Resistance: Delrin stands out for its resistance to a wide range of solvents, hydrocarbons, and neutral chemicals.

Machining Delrin: What to Consider

- Tooling: Utilizing sharp tools and adhering to appropriate speeds and feeds is vital to prevent melting during machining.

- Cooling: Effective cooling methods should be employed to minimize heat generation and ensure dimensional stability.

- Handling: Due to its sensitivity to moisture, proper storage and handling are crucial to maintain its properties.

Applications in Various Industries

- Automotive: Delrin is used for manufacturing gears, bearings, and other components due to its wear resistance and low friction.

- Medical: Its biocompatibility and ability to be sterilized make it suitable for surgical tools and medical devices.

- Consumer Electronics: Delrin’s insulating properties make it ideal for electrical components like switches, insulators, and gears.

Designing with Delrin in Mind

When designing for CNC machining with Delrin, considerations like maintaining uniform wall thickness, incorporating radii to reduce stress concentrations, and ensuring proper tolerances are vital to optimize the machining process and final product.

Stay Updated with Our Latest

Keep the momentum of learning going! Here are some of our latest articles that complement what you’ve just read.

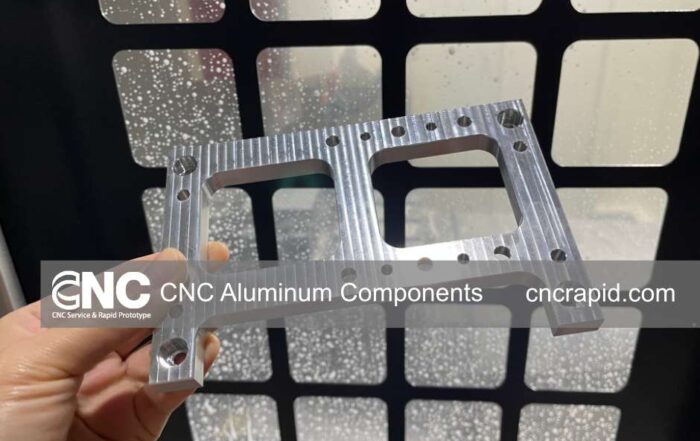

Precision CNC Aluminum Components for Automation Equipment

At CNC Rapid, we specialize in delivering high-quality, Custom Precision CNC Aluminum Components specifically designed for automation systems. Whether you’re building complex robotic arms, sensor housings, or precision mechanical assemblies, our CNC parts meet the [...]

Precision CNC Machined 1045 Steel Components

When engineers and designers search for a reliable material for critical mechanical components, 1045 steel often tops the list. Known for its excellent strength, machinability, and affordability, this versatile medium carbon steel is widely used [...]

Custom CNC Machined Parts for Electronic Devices by CNC Rapid

Custom CNC machined parts are essential for the performance, design, and durability of electronic devices. CNC Rapid’s commitment to precision, customization, and quality makes us the ideal partner for your custom part needs. With a [...]

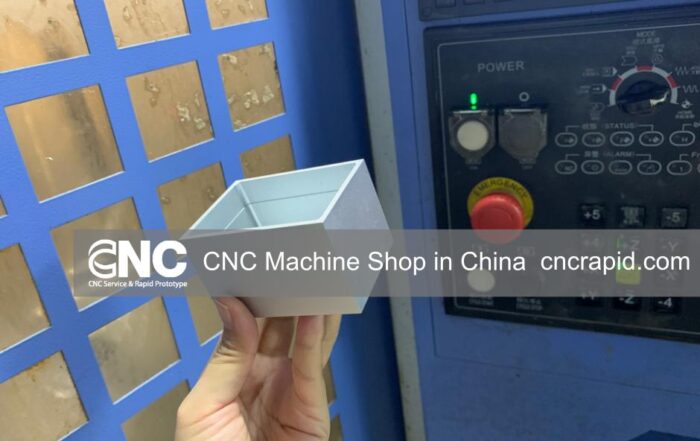

CNC Rapid – CNC Machine Shop in China for Custom Parts

At CNC Rapid, we pride ourselves on our extensive experience and technical strength in CNC machining. Our team of skilled engineers and technicians use the latest technology and machinery to deliver precise, high-quality custom parts [...]

Full CNC Machining Services by CNC Rapid

At CNC Rapid, we are dedicated to providing full CNC machining services that drive your success. Our commitment to quality, precision, and customer satisfaction ensures that you receive the best products for your needs. Contact [...]

Custom CNC Machining for Telecommunication Equipment

Custom CNC machining is a important element in the telecommunication sector's ongoing quest for better connectivity and more reliable networks. At CNC Rapid, we are proud to contribute to this dynamic industry, providing precision machining [...]