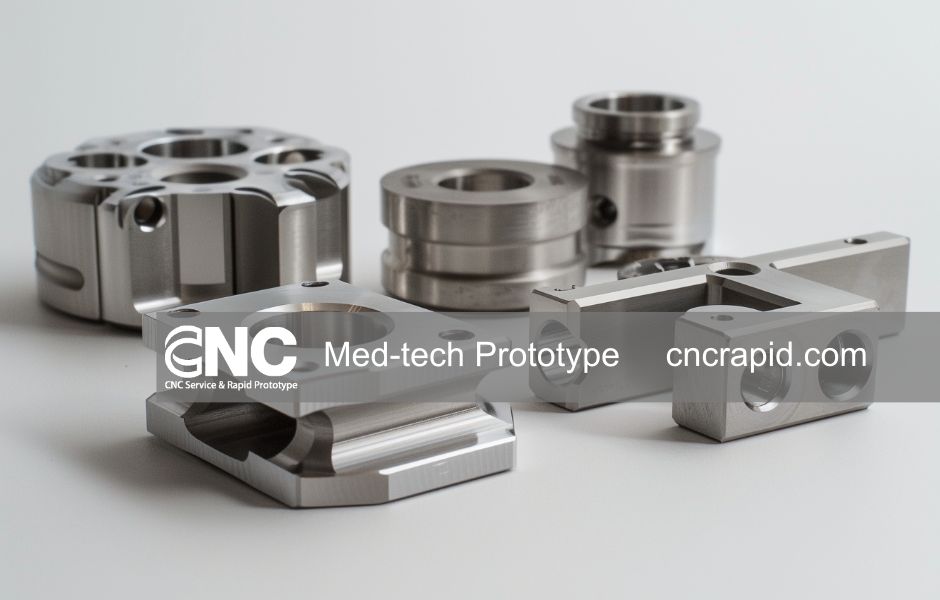

Med-tech prototype, the early models of medical devices and tools, are crucial for advancing healthcare. These prototypes allow for testing and improvement before the final products are made. At the forefront of crafting these vital prototypes is CNC machining, a technology that combines precision, customization, and efficiency.

What is CNC Machining?

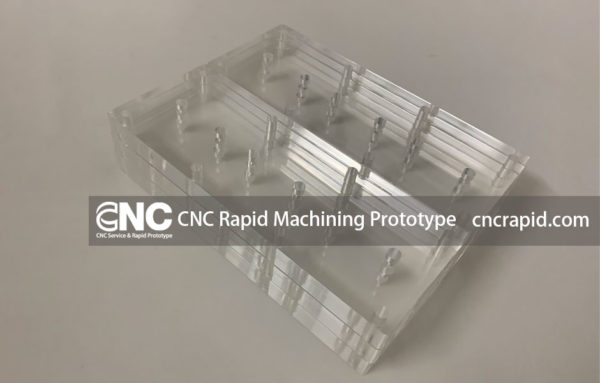

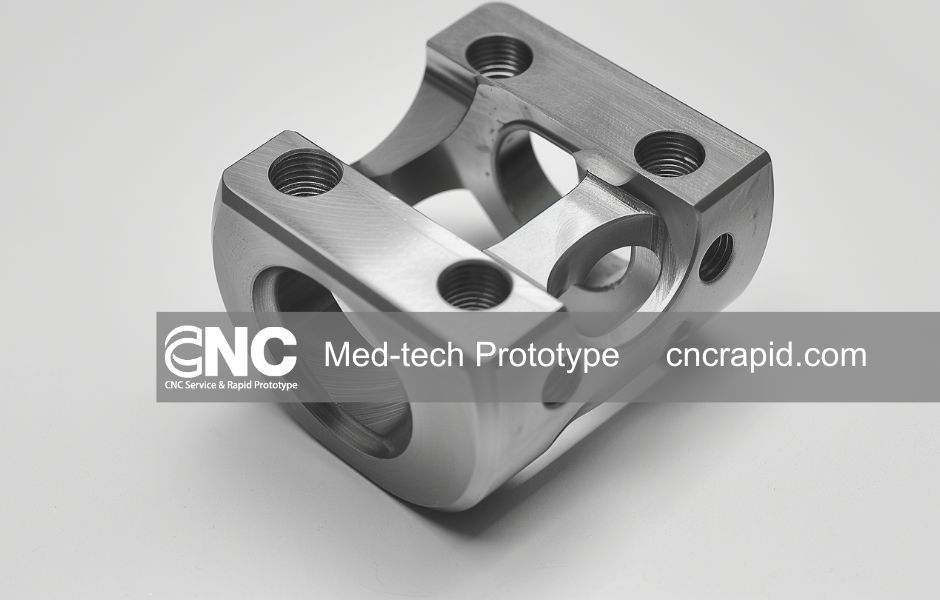

CNC machining is a process where computers control machine tools to make intricate shapes and detailed parts. Unlike manual production, this method stands out for its accuracy, speed, and consistency. It’s an ideal choice for manufacturing prototypes of medical devices.

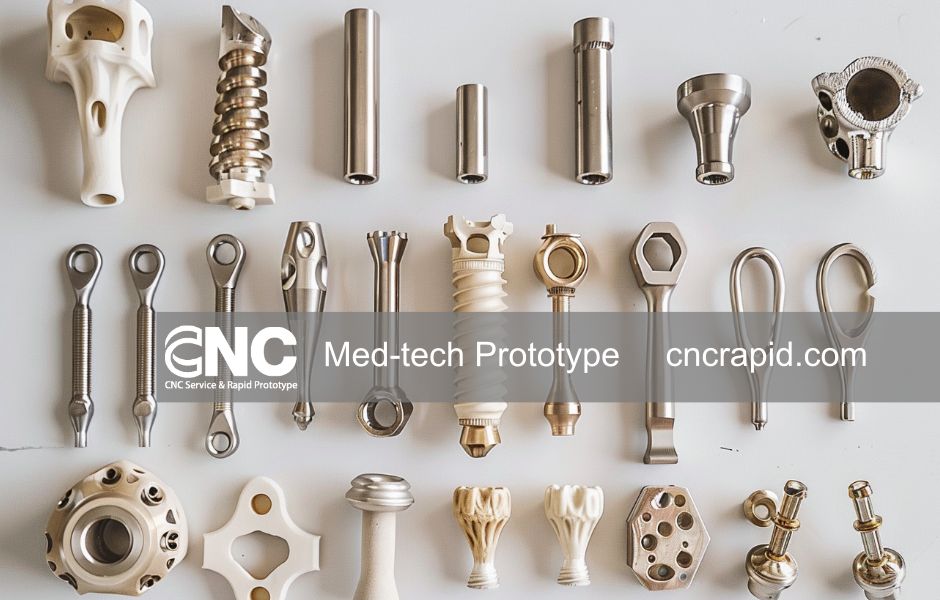

Applications of Med-tech Prototype

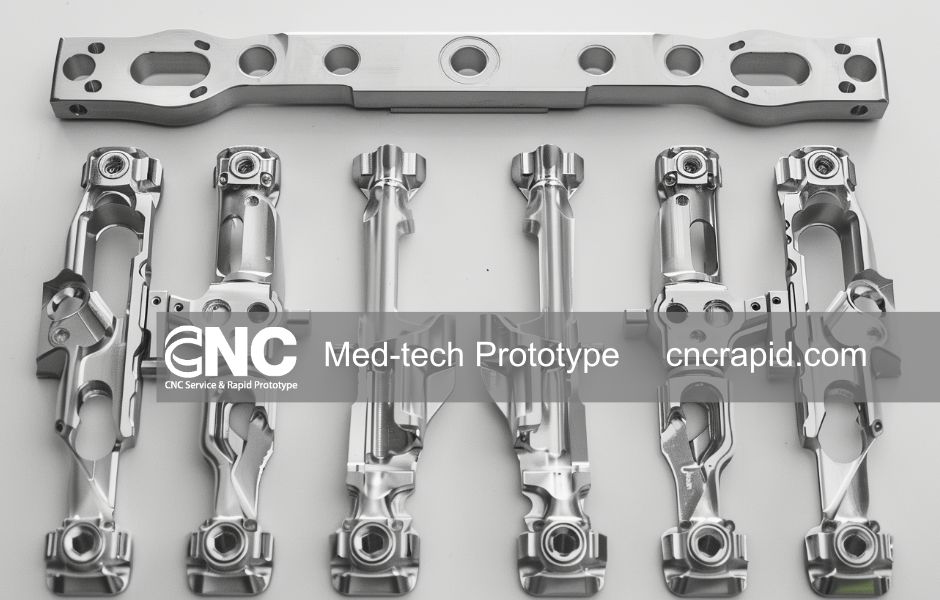

Surgical Tools: Creating prototypes for surgical instruments with CNC machining ensures high precision. Such accuracy is essential for tools like scalpels and forceps, which must perform flawlessly during surgeries.

Implants: CNC machining is also indispensable for making prototypes of implants, such as those for joint replacements or dental applications. These prototypes have to adhere to stringent standards to ensure they are safe and effective when used in patients.

|

|

|

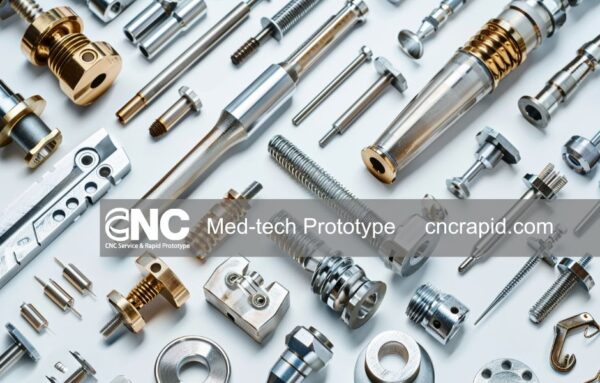

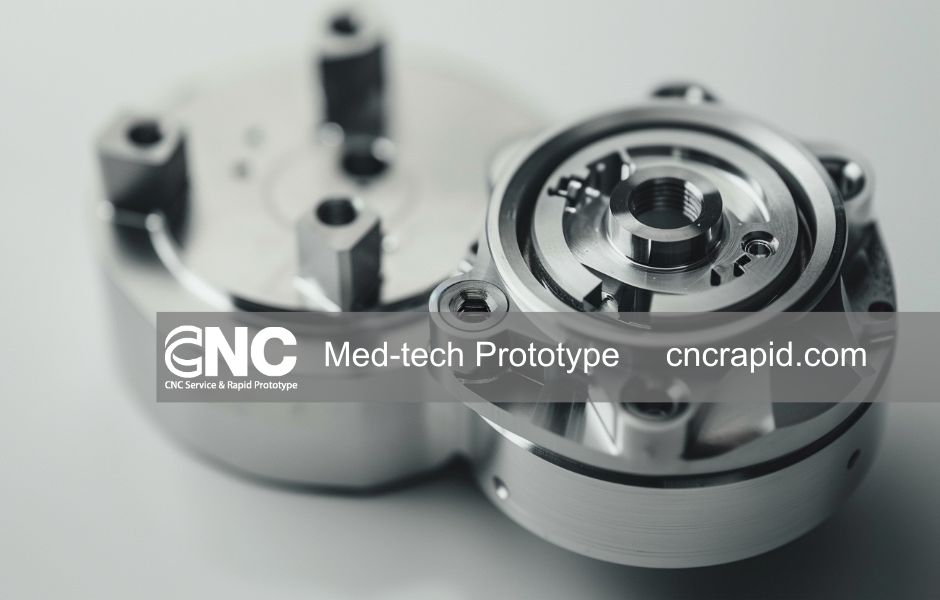

Diagnostic Equipment: Components for diagnostic machinery, like parts of imaging devices, are produced through CNC machining. The quality of these components is critical, as it affects the accuracy of diagnostic results, which in turn impacts patient care.

|

|

Wearable Medical Devices: For wearable devices that monitor health conditions, such as heart rate monitors, CNC machining helps in developing accurate and reliable prototypes. These devices require precise engineering to ensure they are comfortable for the user and provide accurate data.

|

|

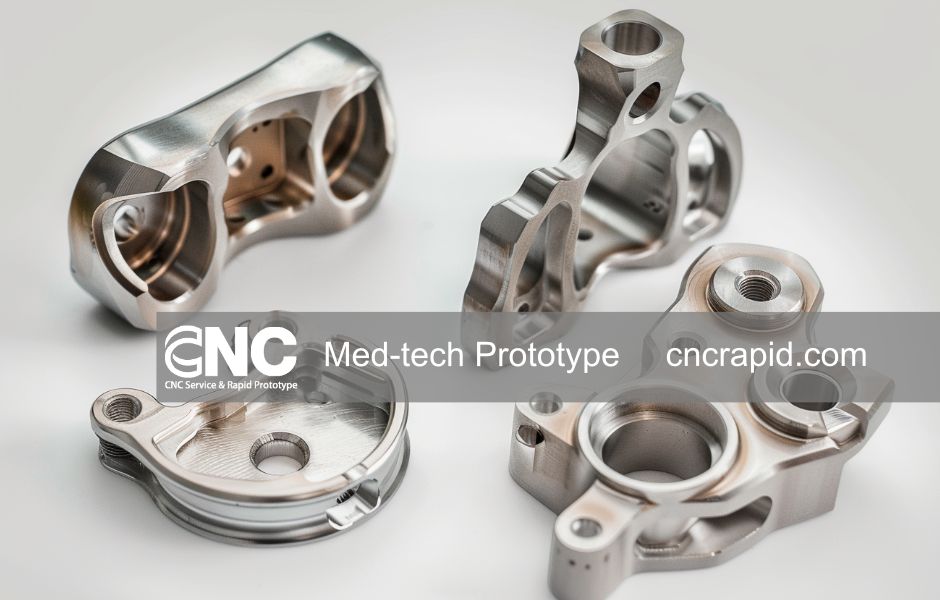

Advantages of CNC Machining in Making Med-tech Prototype

CNC machining brings several benefits to the production of med-tech prototypes:

- Precision and Consistency: It delivers parts that exactly match the design specifications every time, which is crucial for medical devices where precision is non-negotiable.

- Rapid Prototyping: The ability to quickly transform designs into tangible prototypes accelerates the development process of medical technologies.

- Material Flexibility: CNC machines can handle a wide array of materials, enabling prototypes to be made from the most suitable materials for their intended use.

- Cost Efficiency for Small Runs: Though the initial setup for CNC machines can be costly, they are economical for producing small quantities of prototypes. This is because they minimize waste and reduce the need for manual labor.

Future Perspectives

With ongoing advancements in technology, integrating CNC machining with other techniques like 3D printing will broaden the possibilities for med-tech prototypes, enabling more material options and greater customization.

CNC machining plays a critical role in the development of med-tech prototypes, offering unmatched precision, speed in prototyping, and the versatility of material use. As technology evolves, the importance of CNC machining in the field of medical technology development is poised to increase, leading to more sophisticated medical treatments and innovations.

About CNC Rapid

Welcome to CNC Rapid, your trusted partner in med-tech prototype manufacturing. We specialize in creating high-quality prototypes using advanced CNC machining technology. Our team is committed to precision, efficiency, and adaptability, making us a leader in the medical prototype industry.

With our expertise, we support projects from surgical tools and implants to diagnostic equipment and wearable devices. Our rapid prototyping services accelerate the development process, reducing costs and bringing innovative medical solutions to market faster.

Choose CNC Rapid for your prototype needs and join us in shaping the future of medical technology.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!