CNC Turning Company. DFM Rapid is a leading provider of CNC turning services. With a team of experienced machinists and advanced CNC lathes, we are able to produce high-quality parts and components for a wide range of industries. Our commitment to precision and accuracy ensures that all of our parts meet or exceed customer specifications. Whether you need a single prototype or a large production run, we have the capabilities and expertise to deliver the parts you need on time and within budget.

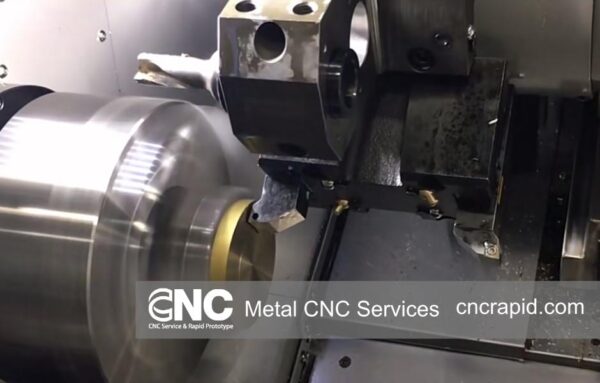

CNC turning is a manufacturing process in which a lathe is controlled by a computer to remove material from a workpiece to create the desired shape. It allows for precise and automated control of the cutting tools, making it a highly efficient and accurate method for producing a wide range of parts and components. CNC lathes can be used to machine a wide range of materials, including metals such as steel, aluminum, and brass, as well as plastics, composites, and various alloys.

CNC turning is suitable for a wide range of parts and components

- Cylindrical: CNC lathes are typically used to produce parts with cylindrical geometries, such as shafts and gear blanks.

- Conical: CNC lathes can be used to produce parts with conical geometries, such as tapered shafts and cones.

- Contoured: CNC lathes can be used to produce parts with complex contoured surfaces, such as gear teeth, splines, and fillets.

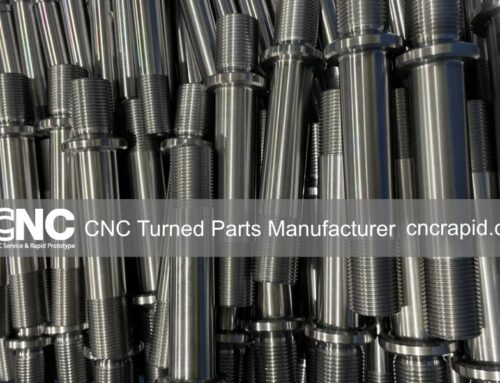

- Threaded: CNC lathes are commonly used to produce parts with internal and external threads, such as bolts, screws, and studs.

- Multi-axis: Some CNC lathes are equipped with multiple axes of motion, which allows for the production of parts with more complex geometries, such as helical shapes and curved surfaces.

Why Choose CNC Turning?

- High precision and accuracy: CNC turning allows for precise control of the cutting tools, which means that parts and components can be produced with very high tolerances and dimensional accuracy. This is especially important for applications where tight tolerances are critical, such as in the aerospace and medical industries.

- Increased efficiency and productivity: CNC turning is a highly automated process, which means that it can be performed quickly and with minimal operator intervention. This can lead to increased production rates and lower unit costs.

- Versatility: CNC turning can be used to produce a wide range of parts and components, including those with complex geometries and intricate details. This makes it a versatile manufacturing process that can be used for many different applications.

- Repeatability: Because the cutting tools are controlled by a computer program, CNC turning can be repeated consistently to produce identical parts and components. This is useful for applications where multiple parts are needed, such as in mass production.

- Reduced waste: CNC turning allows for precise control of the cutting tools, which means that less material is wasted during the manufacturing process. This can result in cost savings and improved environmental sustainability.

CNC lathes are used to produce parts and components for a wide range of industries, including:

- Aerospace: CNC lathes are used to produce precision parts for aircraft and spacecraft, such as engine components, gears, and hydraulic actuators.

- Automotive: CNC lathes are used to produce a variety of parts for the automotive industry, including engine and transmission components, drive shafts, and steering components.

- Medical: CNC lathes are used to produce precision parts for medical devices, such as implants, surgical instruments, and prosthetics.

- Defense: CNC lathes are used to produce parts for military equipment, such as weapons systems, vehicles, and protective gear.

- Energy: CNC lathes are used to produce parts for the energy industry, such as turbine blades, valve components, and pump housings.

- Other industries: CNC lathes are also used in a variety of other industries, such as consumer goods, electronics, and construction.

If you are interested in learning more about our CNC turning capabilities, or if you would like to discuss a specific project, please don’t hesitate to get in touch. We would be happy to answer any questions you may have and provide a quote for your project. Contact us today to learn more!

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!