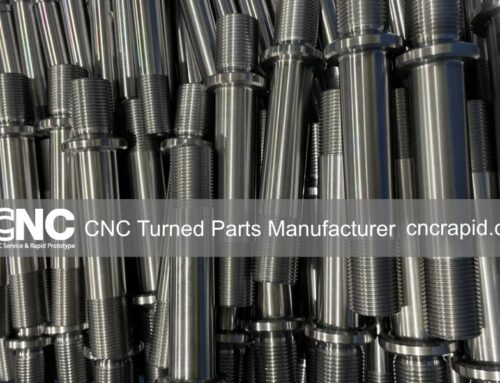

At CNC Rapid, we specialize in producing high-quality CNC Machined Shaft that meet the strict requirements of engineers, designers, and manufacturers around the world. One of our recent projects showcases a custom aluminum shaft, manufactured using precision CNC turning and finished with a durable black anodized coating. This part highlights not only the accuracy of our machining capabilities but also the versatility of our surface finishing options.

CNC Turning for Custom Shafts

CNC turning is the preferred method when manufacturing cylindrical parts such as rods, pins, and shafts. The process allows us to achieve tight tolerances, smooth surface finishes, and precise geometries that are essential for both functional and aesthetic purposes.

For this shaft:

- Material: Aluminum alloy, chosen for its strength-to-weight ratio and machinability.

- Process: CNC turning combined with drilling operations to produce end holes for assembly.

- Length & Geometry: The long shaft design required stable machining setups to ensure concentricity and straightness throughout the part.

By using advanced CNC lathes, we ensured that the shaft’s critical dimensions met strict tolerance requirements, guaranteeing a perfect fit in the client’s assembly.

Black Anodized Finish for CNC Machined Shaft

Surface finishing is often just as important as the machining itself. For this project, we applied a black anodized coating, which provides several advantages:

- Corrosion resistance – protects the aluminum against oxidation.

- Enhanced durability – improves wear resistance.

- Professional appearance – creates a sleek matte black look, suitable for visible or consumer-facing components.

- Electrical insulation – useful in electronic or mechanical assemblies where conductivity must be controlled.

The combination of CNC precision and anodizing ensures that the shaft is not only functional but also visually appealing and long-lasting.

Applications of CNC Machined Shaft

Custom aluminum shafts like this one are widely used across different industries, including:

- Electronics – as supporting rods or alignment shafts in devices.

- Robotics – for arms, joints, and linear motion assemblies.

- Automotive – as lightweight yet durable connecting components.

- Prototyping – for testing designs before moving into mass production.

By machining prototypes and low-volume parts, we help our clients validate their designs quickly and cost-effectively.

Why Choose CNC Rapid for Custom Machining

Our clients trust us because we combine advanced CNC technology with years of manufacturing experience. With CNC Rapid, you can expect:

- Fast turnaround – ideal for prototyping and urgent projects.

- Tight tolerances – ensuring reliability and performance.

- Material versatility – from aluminum and steel to plastics and specialty alloys.

- Surface finishing options – anodizing, passivation, bead blasting, and more.

- Global shipping – serving engineers and companies across Europe, America, and Australia.

Whether you need one prototype or a batch of custom shafts, we can deliver parts that meet your exact requirements.

Contact CNC Rapid Today!

If you are looking for custom CNC machining services for shafts, rods, or other precision components, CNC Rapid is here to help. Contact us today to discuss your project and get a fast quote.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!