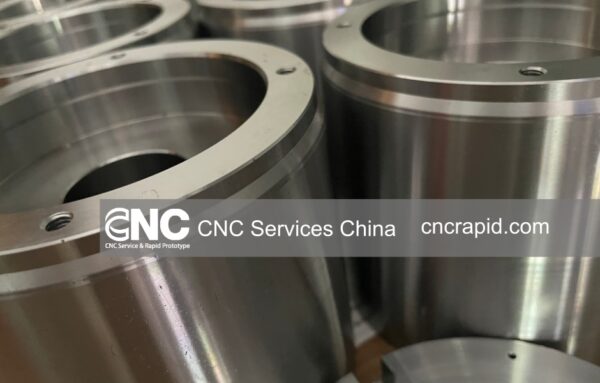

At CNC Rapid, we specialize in 1018 steel CNC machining, delivering high-quality, custom-machined parts for a variety of industries. 1018 steel, a low-carbon steel known for its strength and versatility, is widely used for components that require precision and durability. Our advanced CNC machining technology ensures that we produce steel parts with exceptional accuracy, consistency, and quality, meeting the unique specifications of our clients.

Why Choose 1018 Steel?

Strength and Durability

1018 steel is a low-carbon steel that offers an excellent balance between strength and machinability. Its durability makes it a popular choice for components that need to withstand stress, pressure, or wear over time. This type of steel is commonly used in applications such as automotive parts, machinery components, and structural elements where toughness is crucial.

Machinability

One of the key advantages of 1018 steel is its machinability. It can be easily cut, shaped, drilled, and finished, allowing for precise and complex designs to be achieved through CNC machining. This makes 1018 steel an ideal material for custom parts that need to be manufactured to tight tolerances and specific design requirements.

Weldability and Versatility

Another benefit of 1018 steel is its weldability, which makes it easier to incorporate into larger assemblies. It is also versatile enough to be used in a wide range of industries, including automotive, construction, aerospace, and manufacturing.

CNC Machining for 1018 Steel Components

Precision and Accuracy

At CNC Rapid, we utilize advanced CNC machines to ensure the precision machining of 1018 steel components. Our advanced multi-axis machines allow us to create intricate geometries, sharp edges, and smooth finishes, all while maintaining tight tolerances. This ensures that every component we produce meets the client’s exact specifications and performs optimally in its intended application.

Custom Solutions for Complex Parts

Whether you need simple parts or highly complex designs, CNC Rapid can deliver custom solutions that match your needs. Our CNC machines can handle a wide range of part sizes and geometries, and our team of skilled engineers and machinists work closely with clients to ensure that every detail is executed perfectly.

Applications of 1018 Steel CNC Machined Parts

1018 steel is used in various industries, thanks to its strength, machinability, and versatility. Some common applications of CNC machined 1018 steel parts include:

- Automotive Components: Shafts, gears, and fasteners that need to withstand high stress.

- Industrial Machinery: Custom components like couplings, brackets, and support structures.

- Construction: Structural elements that require durability and stability.

- Manufacturing Tools: Custom dies, fixtures, and other precision parts for manufacturing.

Surface Finishing and Post-Machining Services

High-Quality Surface Finishing

At CNC Rapid, we understand that the performance and aesthetics of your parts are equally important. We offer a variety of surface finishes for 1018 steel parts, including powder coating, painting, and galvanizing, to enhance the durability and appearance of your components. These finishes also provide additional protection against corrosion and wear, ensuring the longevity of your parts.

Post-Machining Services

In addition to precision machining, CNC Rapid provides post-machining services to ensure that your components are ready for use as soon as they arrive. This includes deburring, surface polishing, and any other finishing processes required to meet your specific needs.

Quality Assurance

At CNC Rapid, quality is at the core of everything we do. Every 1018 steel part we machine undergoes rigorous quality control measures to ensure that it meets our high standards of precision, accuracy, and durability. We use advanced inspection tools such as coordinate measuring machines (CMM) to verify that each component adheres to the client’s specifications. This dedication to quality allows us to deliver parts that perform reliably in even the most demanding applications.

Why Choose CNC Rapid for 1018 Steel CNC Machining?

Expertise and Technology

CNC Rapid’s combination of cutting-edge technology and skilled expertise makes us a leading provider of 1018 steel CNC machining services. Our multi-axis CNC machines, along with our highly trained team, ensure that we can handle even the most complex machining projects with precision and efficiency.

Customization and Flexibility

We understand that every project is unique. That’s why we work closely with our clients to provide fully customized solutions. Whether you need a single prototype or a large production run, CNC Rapid can scale to meet your needs while maintaining the highest standards of quality and precision.

Fast Turnaround Times

Our advanced technology and streamlined production processes enable us to offer fast turnaround times without compromising on quality. Whether you have a tight deadline or need to get your parts into production quickly, CNC Rapid is equipped to deliver on time.

Let CNC Rapid be your Partner

CNC Rapid is your trusted partner for high-precision 1018 steel CNC machining services. With our advanced CNC technology, skilled team, and commitment to quality, we deliver custom solutions that meet the specific needs of your project. Whether you require components for automotive, industrial, or construction applications, CNC Rapid has the expertise and technology to bring your designs to life with precision and accuracy.

Contact CNC Rapid Today!

For high-quality 1018 steel CNC machining solutions, contact CNC Rapid today. Our team of experts is ready to assist you with custom machining services that meet your exact requirements. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s machining capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!