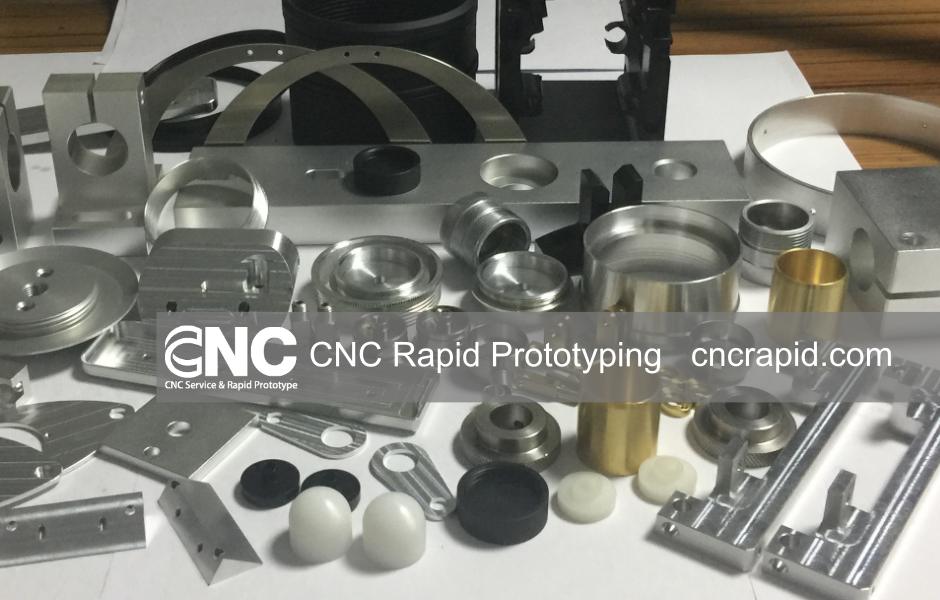

In the world of manufacturing and design, the journey from conceptualization to realization is often fraught with challenges. At DFM Rapid, also known as CNC Rapid, we aim to simplify this process and bring your innovative ideas to life with the power of CNC rapid prototyping.

What is CNC Rapid Prototyping?

CNC rapid prototyping is a manufacturing process that swiftly turns a digital design into a physical model. By leveraging computer numerical control (CNC) technology, we can create prototypes with high precision and intricate details.

The process begins with a 3D design created on a computer. Once the design is complete, a CNC machine meticulously follows the design, carving out the prototype from a chosen material. This method enables us to develop accurate and reliable prototypes quickly, significantly accelerating the product development cycle.

The Benefits of Rapid Prototyping

Rapid prototyping offers several key benefits. First and foremost, it allows you to test the design and functionality of your product before full-scale production. This reduces the risk of costly errors during the manufacturing process.

Additionally, rapid prototyping enables design flexibility. Changes can be made easily to the digital model, which can then be re-machined, reducing the time and cost associated with traditional prototyping methods.

Our Range of Prototyping Services

At CNC Rapid, we offer a variety of prototyping services to meet your specific needs:

Custom CNC Parts

We manufacture custom CNC parts with exceptional precision. Our CNC machines are guided by advanced computer software that follows a 3D model of the part, delivering exceptional accuracy and consistency.

CNC Prototype Machining

With CNC prototype machining, we create a test version of your product before moving into full-scale production. This offers an opportunity to test and refine the product, ensuring it’s perfect before you invest in mass production.

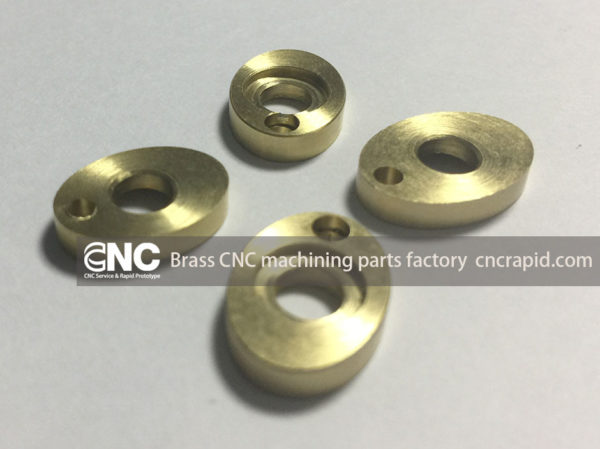

Brass CNC Machining Parts

Our brass CNC machining parts are used widely in the plumbing, electrical, and car industries. Brass, a durable material made from copper and zinc, is resistant to rust and ensures the longevity of your components.

Custom Plastic Parts

We also offer CNC machining for custom plastic parts. This versatile process allows us to create a wide variety of plastic parts, shaping the plastic materials into complex shapes with absolute precision.

Contact us

Turning ideas into reality is at the heart of what we do at CNC Rapid. Through CNC rapid prototyping, we are able to help businesses and individuals alike bring their concepts to life quickly and accurately. Whether it’s custom parts, prototypes, or specific materials like brass or plastic, we’ve got the expertise and technology to deliver high-quality results.

At CNC Rapid, your imagination is the only limit. Let’s shape the future together.

Get a Quote now!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- The name of the part

- A 3D drawing

- The quantity required

- Preferred material

- Tolerance range

- Desired surface finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!