At CNC Rapid, our commitment to precision and quality sets us apart in the custom machining industry. Today, we delve into the intricate process of machining cylindrical parts, specifically focusing on the creation of holes and grooves.

Design and Preparation

Initial Design Phase

The journey of crafting a high-precision cylindrical part begins with a meticulous design phase. Our engineering team collaborates closely with clients to understand their specific requirements and create detailed CAD models. These models serve as blueprints, guiding every step of the machining process.

Material Selection

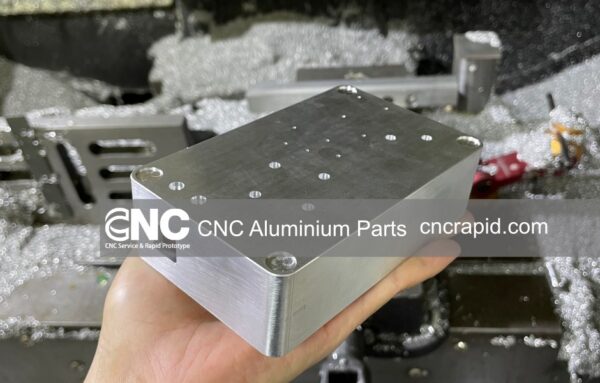

Selecting the right material is crucial for the performance and durability of the part. For cylindrical components, materials such as aluminum, steel, and brass are commonly used due to their excellent machinability and strength. Each material is carefully inspected to ensure it meets our stringent quality standards before machining begins.

|

|

|

CNC Machining Process

Setting Up the CNC Machine

The first step in the machining process is setting up the CNC machine. Our technicians ensure that the cylindrical blank is securely clamped and aligned in the machine. This setup is vital for achieving precise and consistent results.

Machining Holes

Creating holes in cylindrical parts requires high precision. Using advanced CNC drilling and boring tools, we can achieve tight tolerances and smooth finishes. The process involves:

- Drilling: Initial creation of the hole using a CNC drill bit.

- Boring: Refining and enlarging the hole to the exact specifications.

- Deburring: Removing any burrs or rough edges to ensure a clean finish.

Machining Grooves

Grooves are essential features in many cylindrical parts, providing functionality such as securing rings or facilitating assembly. Our CNC machines utilize specialized cutting tools to create grooves with high precision. The process includes:

- Programming: Inputting the exact dimensions and path for the groove into the CNC machine.

- Cutting: Using a precision tool to cut the groove along the specified path.

- Inspection: Checking the groove for accuracy and smoothness.

Techniques and Tools

Advanced Techniques

Our expertise in CNC machining allows us to employ advanced techniques such as:

- Multi-Axis Machining: Enhancing flexibility and precision by allowing the tool to approach the part from different angles.

- High-Speed Machining: Reducing production time while maintaining high accuracy and surface finish quality.

Specialized Tools

We use a variety of specialized tools to achieve the desired features, including:

- Carbide Drills and End Mills: Known for their durability and precision.

- Boring Bars: For creating and refining internal holes.

- Grooving Inserts: Designed specifically for cutting grooves in cylindrical parts.

Quality Assurance

Quality Control Measures

Quality assurance is integral to our machining process. Each part undergoes multiple inspections to ensure it meets the specified dimensions and tolerances. Our quality control measures include:

- Dimensional Inspection: Using coordinate measuring machines (CMM) to verify the dimensions.

- Surface Finish Inspection: Ensuring the surface meets the required smoothness and quality.

- Visual Inspection: Checking for any visible defects or inconsistencies.

Applications and Benefits

Industry Applications

Cylindrical parts with precise holes and grooves are essential in various industries, including:

- Automotive: Components such as pistons and shafts.

- Aerospace: High-precision parts for engines and landing gear.

- Electronics: Housings and connectors requiring exact fits.

Benefits

The benefits of precision CNC machining for cylindrical parts include:

- High Accuracy: Ensuring parts fit and function perfectly.

- Consistency: Maintaining uniformity across large production runs.

- Efficiency: Reducing production time and costs through advanced machining techniques.

Precision CNC machining of cylindrical parts, particularly those requiring holes and grooves, is a testament to CNC Rapid’s expertise and commitment to quality. Our advanced techniques, specialized tools, and rigorous quality control measures ensure that we deliver high-quality components tailored to our clients’ needs.

Contact CNC Rapid Today!

For top-quality, custom CNC machined cylindrical parts, contact CNC Rapid today. Our team of experts is ready to assist you with tailored solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s manufacturing capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!