CNC machined parts service has the potential to transform your manufacturing process and help your business achieve new levels of efficiency and success. By selecting the right service provider and leveraging the benefits of CNC machining, you can unlock the full potential of this cutting-edge technology and stay ahead of the competition. Our company, DFM Rapid, is a perfect choice for businesses seeking top-notch CNC machining services.

Automotive Industry: Our facility is equipped with advanced CNC machinery capable of producing high-precision parts for a wide range of automotive applications. From engine components to custom fixtures for automotive assembly lines, we provide comprehensive solutions that enhance performance and reliability. Our expertise extends to developing prototypes that aid in the rapid development and testing of new automotive technologies.

Medical Industry: We understand the critical nature of medical device manufacturing. Our machined parts are produced in a controlled environment to meet the exacting standards of the medical field. Whether it’s surgical instruments, orthopedic implants, or components for diagnostic equipment, our CNC machining services ensure optimal precision and compatibility with the most stringent hygienic standards.

Why Choose Us?

- Precision Engineering: Utilizing advanced CNC technology, we achieve tight tolerances that meet the exact specifications of your projects, ensuring high-quality results every time.

- Material Versatility: We work with a diverse range of materials suitable for both automotive and medical applications, including but not limited to stainless steel, aluminum, titanium, and engineered plastics.

- Custom Solutions: Every industry has unique challenges, and we pride ourselves on delivering custom solutions that address your specific needs. Our team collaborates closely with each client to ensure that the final product exceeds expectations.

- Rapid Turnaround: Time is of the essence in both automotive and medical industries. Our optimized processes and dedicated team enable us to deliver your projects quickly without compromising on quality.

- Quality Assurance: Our quality control system is rigorous, and every part we produce is inspected to ensure it meets or exceeds industry standards. We are committed to maintaining the highest levels of quality and reliability.

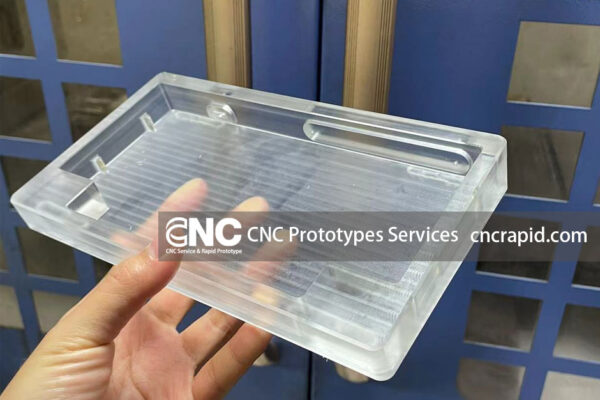

CNC machining is a practical option for everything from prototype manufacturing to production runs. We are a one-stop shop for custom machining and manufacturing.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

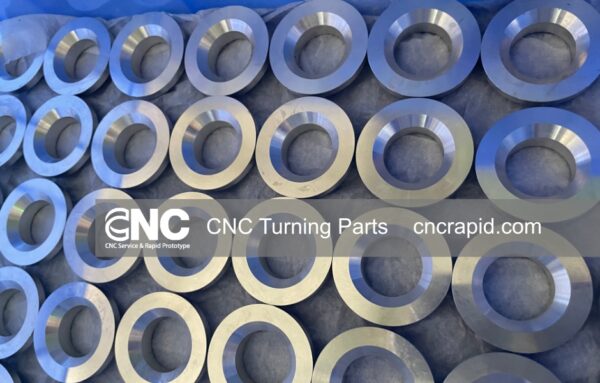

Machined parts service factory

We have over 25 CNC mills, lathes and EDM machines in our factory for all your CNC needs. We also have a multilingual support team to ensure your product development journey is smooth and worry-free. Learn more about our CNC machining services.

At DFM Rapid, we pride ourselves on our ability to deliver high-quality CNC machined components, backed by a team of experienced professionals and cutting-edge technology. Our commitment to customer satisfaction, along with our extensive expertise in the field, ensures that you can trust us with your most complex and demanding projects. Our competitive pricing, quick turnaround times, and dedication to quality assurance make us an ideal partner for all your CNC machining requirements.

By choosing DFM Rapid as your CNC machined parts service provider, you’ll gain a reliable partner dedicated to helping your business achieve new heights of success. Contact us today to discuss your needs and discover how our CNC machining solutions can help your manufacturing process.

Get in Touch

At CNC Rapid Machined Parts Service Factory, we are ready to handle the CNC projects that are crucial for your success in the automotive and medical sectors. Connect with us to discuss how we can bring your next project to life with precision and efficiency.

If you need Metal & Plastic parts machined for Custom CNC Machining or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!