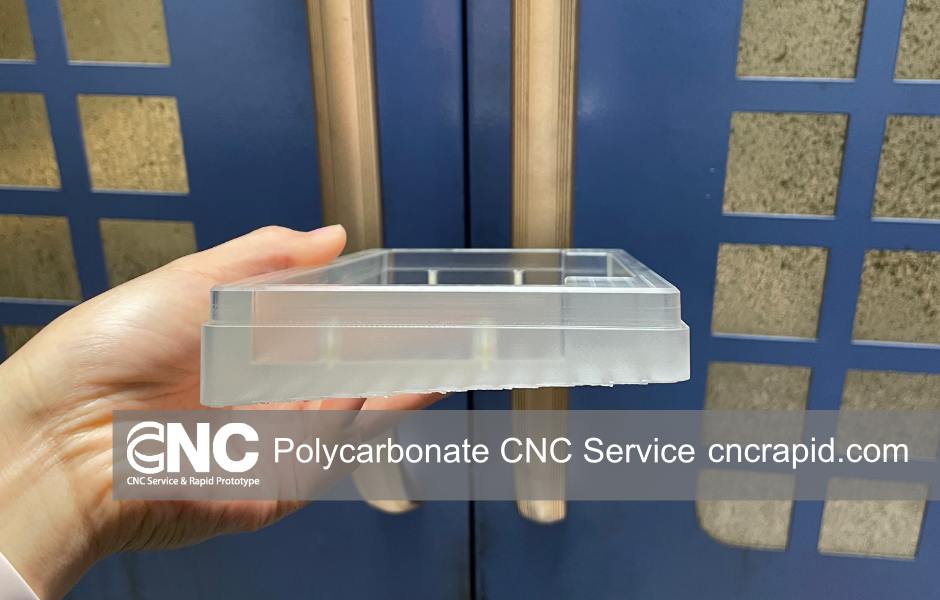

Polycarbonate CNC Service. Polycarbonate is a type of plastic that is known for its strength and durability. It is often used in applications that require transparency. It can be machined using CNC machines. However, it is important to note that polycarbonate can be difficult to work with due to its high melting point and tendency to deform under high heat. This means that special care must be taken when machining polycarbonate to avoid damaging the material. It is also important to use the right cutting tools and techniques to ensure a smooth, accurate finish.

When using a CNC machine to machine polycarbonate, there are a few things we can do to ensure a successful outcome:

- Use high-speed steel or carbide cutting tools specifically designed for machining plastic materials.

- Use a low feed rate to avoid overheating the material and causing it to deform.

- Use a coolant or lubricant to keep the cutting tools and polycarbonate cool and reduce friction.

- Use a vacuum system to keep the polycarbonate securely in place and prevent it from moving or shifting during the machining process.

- Use multiple shallow passes to avoid overheating the material and causing it to deform.

- Use a finishing tool, such as a ball nose end mill, to achieve a smooth, accurate finish.

Overall, the key to successfully machining polycarbonate using a CNC machine is to take your time and use the right tools and techniques to avoid damaging the material.

Polycarbonate is commonly used to make a wide range of products and parts, including:

- Bulletproof glass and windows

- Protective helmets and goggles

- Automotive and aircraft parts

- Medical and laboratory equipment

- Electronics components and housings

- Signage and displays

- Toys and sporting goods

Many of these products and parts are made using CNC machining, as the precision and accuracy of CNC machines allow manufacturers to create complex, high-quality parts with a high level of consistency. CNC machining is particularly well-suited to polycarbonate because it allows manufacturers to achieve a smooth, accurate finish, even on complex, three-dimensional parts. Additionally, CNC machines are capable of working with a wide range of materials, including polycarbonate, making them versatile and valuable tools in the manufacturing process.

At DFM Rapid, we specialize in providing high-quality CNC machining services for a wide range of industries and applications. We have a team of experienced machinists and advanced CNC machines, allowing us to produce precision parts and components with a high level of accuracy and consistency.

We offer CNC machining services for a variety of materials, including polycarbonate and other common materials such as aluminum, steel, and plastic. Our advanced CNC machines allow us to produce parts and components with complex geometries and tight tolerances, making us a trusted partner for companies in need of precision machined parts.

We are proud of the work we do and stand behind our services. In fact, we offer a 100% satisfaction guarantee on all of our CNC machining work. If you’re not completely satisfied with the quality of the parts we produce, we will work with you to make it right.

Whether you need a single prototype or large production runs, our team is ready to assist you with your CNC machining needs. Contact us today to learn more about our services and discuss your project in detail.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!