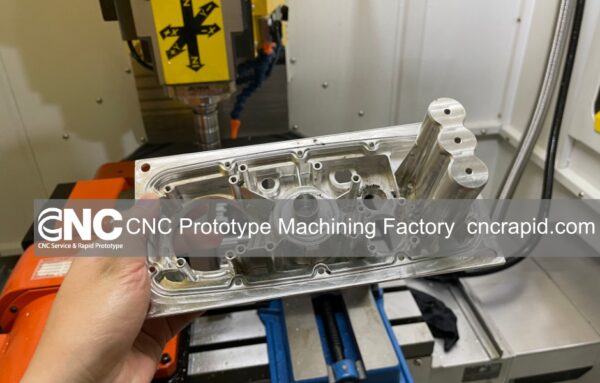

Precision CNC machining is a marvel of modern manufacturing, combining the artistry of design with the science of cutting-edge technology. The process begins with a digital blueprint. Engineers use sophisticated CAD software to draft the intricate designs that CNC machines will follow. The part pictured, a testament to this technology, may have begun as a mere series of vectors on an engineer’s screen, but through CNC machining, it has been transformed into a crucial cog in the automotive wheel.

From Robust Metals to Automotive Mettle

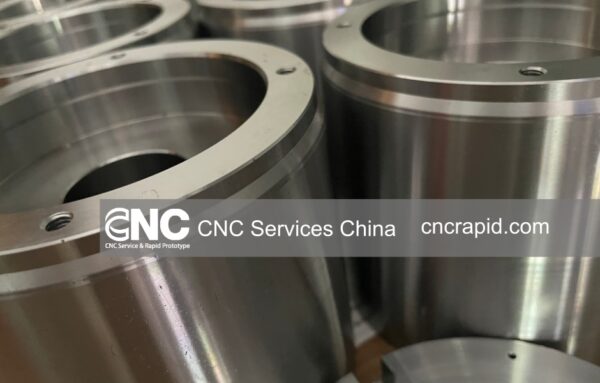

The choice of material is pivotal. The gleaming surface of the featured component suggests a high-grade alloy, selected for its durability and resistance to the stress of a car’s demanding dynamics. Precision CNC machining breathes life into these robust materials, sculpting them with an astonishing level of detail. It is not the metal that dictates the form but the machine that commands the metal.

Automotive Industry: The Stage for Precision Parts

In the automotive industry, every millimeter counts. The component in the image, with its precise slots and geometric precision, could play a vital role in the transmission system, governing the flow of power to the wheels. In the world of high-speed cars, the difference between optimal performance and mechanical failure often rests on the precision of parts like these.

Innovation at the Helm

CNC technology is not a static field; it is driven by continuous innovation. The adoption of multi-axis machines allows for the creation of parts with complex geometries that were once deemed unfeasible. Such advancements could have contributed to the meticulous crafting of the component we see—an artifact that reflects both the history and the future of CNC machining.

Ensuring Excellence through Rigorous Standards

Before parts like the one displayed can take their place in a vehicle, they must undergo stringent testing. Quality control in CNC machining is relentless. Every contour and cut undergoes scrutiny to ensure that each component can withstand the rigors of its intended use. It is a process that marries the unforgiving precision of machines with the meticulous oversight of human expertise.

Overcoming the Ordeal of Accuracy

The path to precision is fraught with challenges. Tool wear, thermal expansion, and material inconsistencies are but a few of the trials faced during the machining process. The flawless condition of the component depicted is a victory over these challenges, achieved through meticulous planning and problem-solving prowess.

The Road Ahead: CNC Machining’s Future

As we stand on the cusp of a new era in manufacturing, the capabilities of CNC machining are only set to expand. With the integration of AI and machine learning, the precision and efficiency of CNC machines will reach new heights, allowing for even more innovative uses in the automotive sector and beyond.

CNC Rapid takes pride in its role as an integral player in the narrative of precision manufacturing. The part depicted here is but one example of our unwavering dedication to excellence. As technology marches forward, so does CNC Rapid, ever committed to being the heartbeat of industrial precision and innovation.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!