At CNC Rapid, we specialize in precision machining, particularly in the fabrication of custom aluminum components. Our extensive experience in CNC Machining China allows us to deliver high-quality, intricately machined parts that meet the exacting standards of our clients. Today, we explore the process and expertise involved in creating a custom aluminum cavity for a base component, showcasing our capabilities and commitment to excellence.

Expertise in Aluminum CNC Machining

Precision Machining for Custom Aluminum Parts

Aluminum is a preferred material for many applications due to its lightweight properties, excellent machinability, and corrosion resistance. At CNC Rapid, we leverage these properties to produce custom aluminum parts with exceptional precision. Our advanced CNC Machine Shop China is equipped with advanced machinery, allowing us to handle complex geometries and tight tolerances required for aluminum components, including intricate cavities.

Creating the Custom Aluminum Cavity

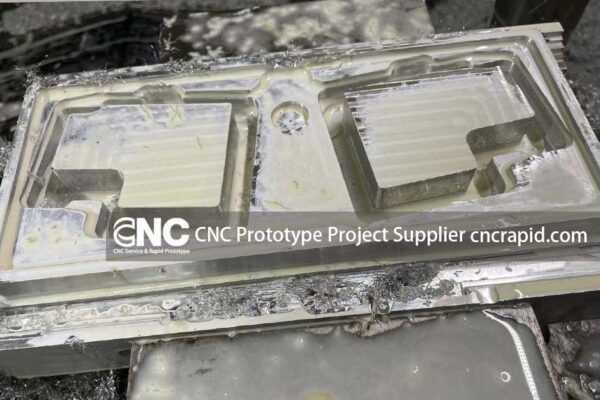

The creation of a custom aluminum cavity requires meticulous attention to detail. Our process begins with a comprehensive understanding of the client’s design specifications. Using cutting-edge CAD software, our engineers develop a detailed model of the cavity, ensuring that all dimensions and features align with the client’s requirements.

Once the design is finalized, the machining process begins. Our high-speed CNC machines are programmed to execute precise cuts and milling operations, gradually shaping the aluminum block into the desired cavity. Throughout this process, our skilled technicians monitor the machining to ensure that every detail is executed flawlessly, resulting in a cavity that meets the highest standards of quality and precision.

Surface Finishing Options

Enhancing the Final Product

In addition to our machining capabilities, CNC Rapid offers a wide range of surface finishing options to enhance the appearance and performance of aluminum parts. These finishes not only improve the aesthetic appeal but also add functional benefits such as increased corrosion resistance, enhanced durability, and improved electrical conductivity.

Some of the surface finishing options we provide include:

- Anodizing: This process adds a protective oxide layer to the aluminum, enhancing its corrosion resistance and allowing for various color options.

- Powder Coating: A durable finish that provides excellent protection against environmental factors, available in a wide range of colors.

- Polishing: Achieving a smooth, reflective surface that enhances the part’s appearance.

- Bead Blasting: A matte finish that adds texture and reduces glare.

These finishing services allow us to deliver fully finished parts that are ready for immediate use in their intended applications.

Supporting Prototype Development

Rapid CNC Machining for Prototypes

At CNC Rapid, we understand the importance of speed and precision in prototype development. Our Rapid CNC Machining services are designed to support clients who need quick turnaround times without compromising on quality. Whether it’s a single prototype or a small batch of parts, we can deliver fully machined and finished components that accurately represent the final product.

Prototyping is a critical phase in product development, and our capabilities in this area ensure that our clients can test and refine their designs before moving into full production. With our advanced machinery and skilled team, we can quickly adapt to design changes and produce prototypes that meet the exact specifications of the project.

CNC Rapid’s expertise in machining custom aluminum parts, particularly those involving complex cavities, is backed by years of experience and advanced technology. Our commitment to precision, combined with our extensive range of surface finishing options, makes us a trusted partner for clients seeking high-quality aluminum components. Whether you need a prototype or a full production run, CNC Rapid is your go-to source for CNC Machining China.

Contact CNC Rapid Today!

For top-quality custom aluminum machining and surface finishing services, contact CNC Rapid today. Our team of experts is ready to assist you with tailored solutions that meet your specific needs. Reach out to us for a consultation or to request a quote, and experience the excellence of CNC Rapid’s machining capabilities.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!