At CNC Rapid, we are dedicated to pushing the boundaries of what CNC technology can achieve, providing our clients with the best in precision machining solutions. If you’re looking to improve the quality of your audio equipment or need precision parts for other applications, consider CNC Rapid as your trusted partner in innovation and excellence.

Understanding CNC Machining

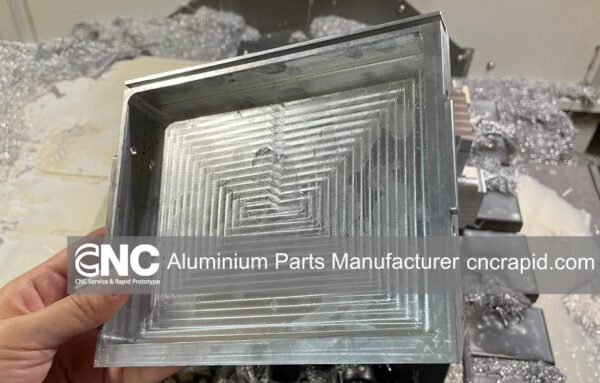

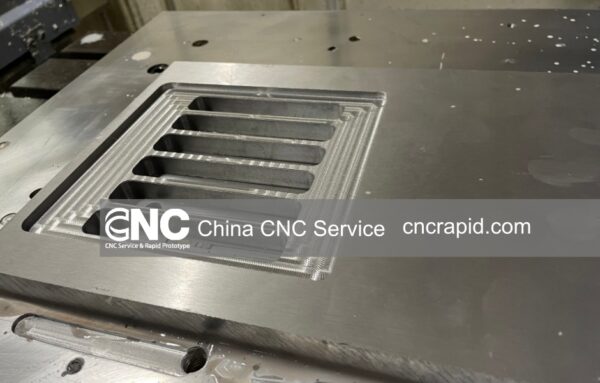

CNC machining is a manufacturing process known for its precision and versatility. It involves the use of computer-controlled machine tools that can produce custom-designed parts with high accuracy. This process uses various tools such as mills, lathes, and grinders to cut and shape materials into the desired form based on digital designs.

The primary advantage of CNC machining is its ability to maintain exact specifications over high volumes, making it ideal for the audio equipment industry where consistency and quality are crucial. Unlike manual machining, CNC provides greater precision, less waste, and a significantly higher production capability.

Why Choose CNC Rapid for Audio-related Components

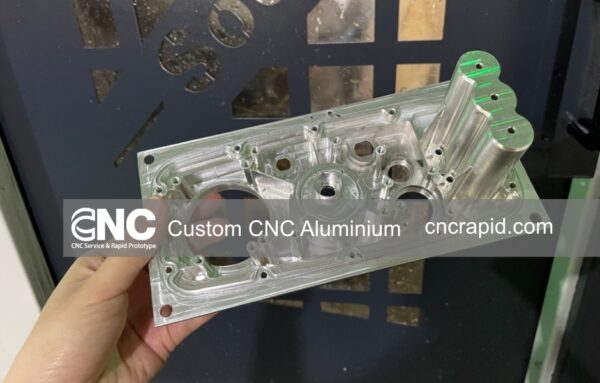

At CNC Rapid, we understand the importance role that component quality plays in the overall performance of audio devices. Our CNC solutions are tailored to produce optimal parts for speakers, headphones, microphones, amplifiers, and other audio-related components.

- Speaker Components: We use CNC machining to create robust and precise frames and housings for speakers. This not only enhances the structural integrity of the speakers but also improves sound quality by minimizing any potential distortion.

- Headphone Parts: Precision is key when machining components for headphones. Our CNC processes ensure that every part from the casing to the intricate internal mechanisms meets stringent quality standards for comfort and durability.

- Microphone Machining: The quality of sound captured by microphones is heavily dependent on the precision of their components. We manufacture microphone casings and internal structures that are crucial for clear and accurate sound transmission.

- Amplifier Parts: Amplifiers require highly conductive and robust components to function effectively. Our CNC machining services provide the precision needed to manufacture complex parts that ensure reliability and efficiency.

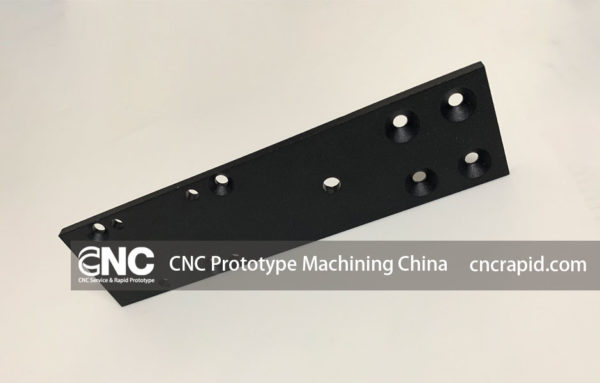

- Aluminum Panels for Audio Equipment: At CNC Rapid, we have extensive experience in machining aluminum panels used in various audio equipment. These panels are not only structurally vital but also aesthetically pleasing, thanks to our range of surface treatments. We offer anodizing, powder coating, and other finishes that enhance durability and corrosion resistance while providing a superior look and feel.

Beyond Audio Equipment: CNC Rapid’s Versatility

While our expertise shines in the audio equipment sector, CNC Rapid’s capabilities extend across various industries. Whether it’s automotive, Industrial Machinery, medical devices, or consumer electronics, our advanced CNC machinery and experienced technicians are equipped to handle diverse machining needs. By partnering with us, you gain access to a team that is committed to delivering high-quality, precision-engineered parts tailored to your specific requirements.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!