CNC Rapid is a leading CNC prototyping supplier that has been providing high-quality, precision parts to businesses of all sizes for over 10 years. But how did we achieve this coveted position? Let’s take a journey through our evolution and the key factors that set us apart.

1. A Commitment to Quality

From our inception, CNC Rapid has been unwavering in its commitment to delivering top-notch quality. Our team understands that in the world of CNC prototyping, even the slightest error can have significant implications. Hence, we’ve invested in advanced machinery and rigorous quality control processes to ensure every prototype meets the highest standards.

2. Continuous Learning and Innovation

The CNC machining industry is ever-evolving, with new techniques, materials, and technologies emerging regularly. At CNC Rapid, we believe in continuous learning. Our team regularly undergoes training, attends industry seminars, and collaborates with experts to stay ahead of the curve.

3. Customer-Centric Approach

Our success is deeply intertwined with the success of our clients. We’ve always prioritized understanding the unique needs of each client and tailoring our services accordingly. This customer-centric approach has not only earned us repeat business but also numerous referrals.

4. Competitive Pricing

While we never compromise on quality, we understand the importance of cost-effectiveness. Through efficient processes, bulk purchasing of materials, and strategic partnerships, we’ve managed to offer competitive pricing, making high-quality CNC prototyping accessible to a wider range of businesses.

5. Rapid Turnaround Times

In today’s fast-paced business environment, time is of the essence. CNC Rapid lives up to its name by ensuring rapid turnaround times without sacrificing quality. Our streamlined processes and dedicated team work round the clock to deliver projects on time, every time.

6. Global Outreach

While we started as a modest venture, our vision was always global. Today, CNC Rapid serves clients from various parts of the world, thanks to our robust logistics network and understanding of global market dynamics.

7. Transparent Communication

We believe in transparent and open communication. Clients are kept in the loop at every stage of the prototyping process, ensuring there are no surprises and that their feedback is incorporated in real-time.

Why Choose CNC Rapid?

CNC Rapid’s journey to becoming a top choice among CNC prototyping suppliers is a testament to our dedication, passion, and relentless pursuit of excellence. As we look to the future, we’re excited about the possibilities and are committed to pushing the boundaries of what’s possible in CNC prototyping.

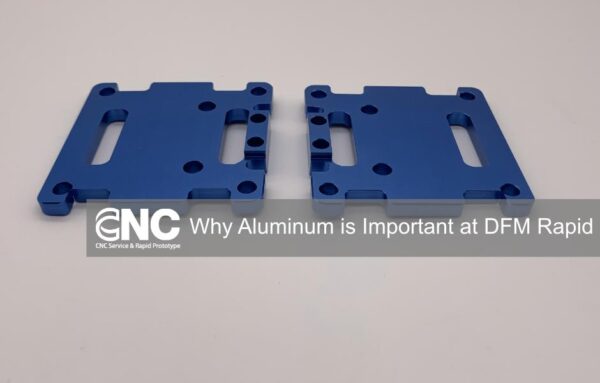

Rapid Prototype Parts

At CNC Rapid, we understand the importance of bringing ideas to life quickly and accurately. Our rapid prototype parts service ensures that you get a tangible representation of your design in the shortest time possible. Using advanced CNC machinery and a team of skilled engineers, we transform your designs into high-quality prototypes that serve as a foundation for further development and testing.

CNC Production Machining

Scaling from a prototype to full-scale production requires precision, efficiency, and consistency. Our CNC production machining services are designed to handle large-scale orders without compromising on quality. With a fleet of advanced CNC machines and a dedicated production team, we guarantee parts that are consistently accurate, meeting the stringent standards of various industries.

CNC Turned Parts Manufacturer China

Specializing in the production of precision turned parts, CNC Rapid has established itself as a leading CNC turned parts manufacturer in China. Whether it’s complex components with intricate designs or bulk orders of simpler parts, our turning centers are equipped to handle projects of any scale. Our expertise in turning ensures that parts are produced with impeccable accuracy and a flawless finish.

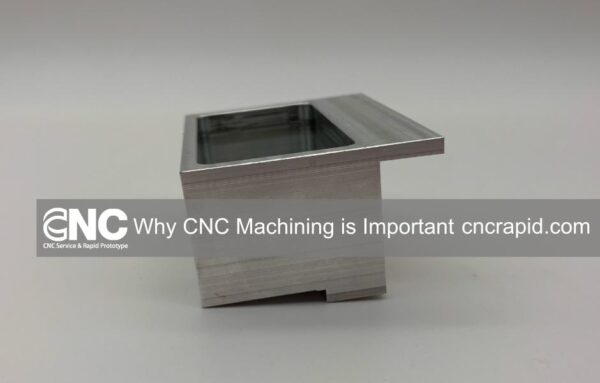

Precision CNC Milling

Precision is at the heart of what we do. Our CNC milling services are tailored to produce parts with intricate details, tight tolerances, and complex geometries. With multi-axis CNC milling machines and a team of experienced operators, we can mill a wide range of materials, ensuring that every part meets the exact specifications of our clients.

Plastic Machining Services

While metals are a common choice for many components, plastics offer versatility, durability, and cost-effectiveness for various applications. At CNC Rapid, we have honed our skills in plastic machining, producing parts that are both functional and aesthetically pleasing. From ABS to Polycarbonate, we work with a wide range of plastics to deliver parts that match your requirements.

Stainless Steel CNC Machining Services

Stainless steel is renowned for its strength, corrosion resistance, and aesthetic appeal. Our stainless steel CNC machining services are designed to leverage these properties, producing parts that are not only strong but also have a polished finish. Whether it’s components for the medical industry or parts for the automotive sector, our stainless steel machining processes ensure precision and durability.

Contact CNC Rapid Today!

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!