CNC machining offers remarkable advantages for automotive prototyping, from its precision and speed to its material flexibility and cost-effectiveness. By enabling rapid iteration and the creation of complex, customized parts, CNC machining is crucial for driving innovation in car design and manufacturing. For automotive companies looking to stay ahead in the race for new and improved vehicles, CNC machining is an invaluable tool.

What is CNC Machining?

CNC machining stands for Computer Numerical Control machining. It’s a process used to control a range of complex machinery, from grinders and lathes to mills and routers, with a computer. This method transforms digital blueprints into physical parts with precise dimensions, which is perfect for creating car prototypes.

Precision and Quality

Cars need parts that fit perfectly and work flawlessly. CNC machining makes this possible by creating prototypes that match the design exactly, every single time. This precision is vital for the automotive industry, where even a small mistake can cause big problems.

Speed and Efficiency

Making prototypes quickly is essential in the car industry. CNC machining shines here by turning designs into real parts much faster than traditional methods. This speed lets engineers test their ideas and make improvements swiftly, helping them to find the best solutions in less time.

Material Flexibility

Another great thing about CNC machining is that it works with many materials, from metals like aluminum and steel to plastics. This flexibility means engineers can experiment with different materials to find the best one for each part of a car.

Cost-Effectiveness

Making prototypes can be expensive, but CNC machining helps save money. It reduces the need for manual labor and minimizes waste, making the prototyping process more economical. Plus, by catching design flaws early, it saves costs on further down the line.

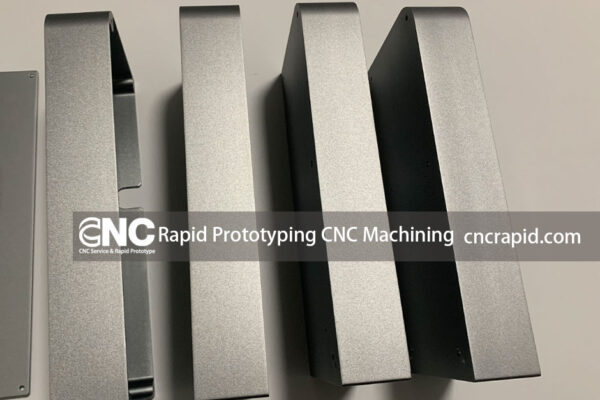

Customization and Complexity

CNC machining is ideal for making complex and customized parts that are often needed in car prototypes. Whether it’s a unique engine component or a custom dashboard, CNC machines can handle intricate designs with ease.

Enhancing Innovation

With CNC machining, engineers can push the boundaries of car design. They can try out bold new ideas, knowing that they can quickly and accurately produce prototypes for testing. This freedom to experiment drives innovation in the automotive industry.

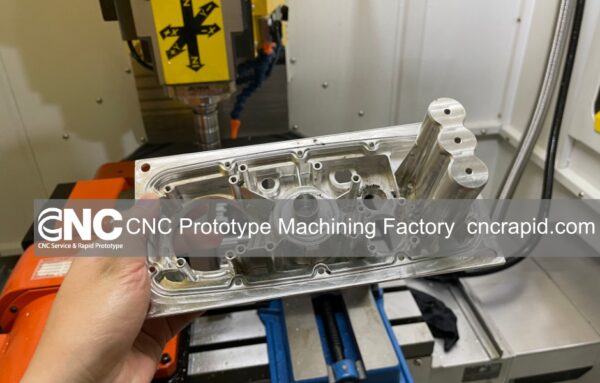

About CNC Rapid

At CNC Rapid, we pride ourselves on being at the forefront of CNC machining technology, offering unparalleled services to the automotive industry and beyond. With years of experience and a commitment to quality, we help turn your innovative ideas into reality.

Our advanced equipment and skilled team are dedicated to providing fast, accurate, and cost-effective prototyping solutions, ensuring your projects move from concept to completion smoothly and efficiently. Whether you’re designing next-generation vehicles or custom automotive components, CNC Rapid is your partner in achieving excellence. Let us help you drive your innovations forward with the precision and speed that only CNC machining can offer.

For more information about our services and how we can assist with your automotive prototyping needs, visit automotive cnc machining or contact us at [email protected]. Together, let’s shape the future of automotive design.