Understanding CNC Machining Prototyping

CNC machining prototyping is a manufacturing process that uses computerized controls to operate and manipulate machinery and tools to create prototype parts and components. This process allows for high precision and accuracy, making it an ideal solution for creating prototypes that closely resemble the final product.

There are many advantages to using CNC machining for prototyping. First, it is a very fast process. CNC machines can cut materials much faster than traditional methods, such as hand-milling or casting. This means that prototypes can be produced in a matter of days, or even hours, depending on the complexity of the part.

Second, CNC machining is very accurate. CNC machines can be programmed to cut materials to within a fraction of a millimeter, which is essential for creating prototypes that are accurate representations of the final product.

Third, CNC machining is very versatile. CNC machines can be used to cut a wide variety of materials, including metals, plastics, and composites. This makes them ideal for prototyping a wide variety of products.

Types of CNC Machining Prototyping

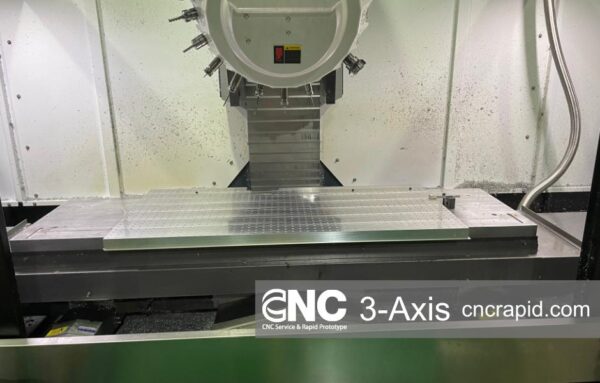

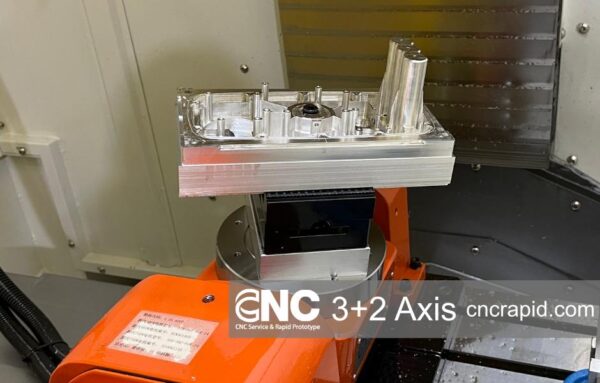

There are three main types of CNC machining prototyping: 3-axis, 4-axis and 3+2-axis.

- 3-Axis: 3-axis CNC machining is the most common type of CNC machining prototyping. The full use of the X, Y, and Z directions makes a 3 Axis CNC mill useful for a wide variety of work.

- 4-Axis: This type of router allows the machine to rotate on a vertical axis, moving the workpiece to introduce more continuous machining.

- 3+2 Axis: 3+2 Axis CNC machining is a more advanced type of CNC machining prototyping. 3+2-axis CNC milling uses a machine with 3 primary axes and 2 rotational axes to efficiently machine complex parts.

Advantages of CNC Machining Prototyping

- Speed: CNC machining is a very fast process, which means that prototypes can be produced in a matter of days, or even hours.

- Accuracy: CNC machines can be programmed to cut materials to within a fraction of a millimeter, which is essential for creating prototypes that are accurate representations of the final product.

- Versatility: CNC machines can be used to cut a wide variety of materials, including metals, plastics, and composites. This makes them ideal for prototyping a wide variety of products.

- Cost-effectiveness: CNC machining is a cost-effective way to produce prototypes, especially for high-volume production.

- Repeatability: CNC machines can be programmed to repeat the same cuts over and over again, which ensures that each prototype is identical.

- Efficiency: CNC machines can be operated by a single operator, which reduces labor costs.

- Safety: CNC machines are designed to be safe to operate, which reduces the risk of accidents.

CNC machining prototyping is a versatile and cost-effective way to create physical prototypes of parts or products. It is a fast, accurate, and versatile process that can be used to cut a wide variety of materials. If you are looking for a way to quickly and accurately prototype your product, CNC machining is a great option.

Why Choose CNC Rapid?

CNC Rapid is a leading provider of CNC machining services in China. We offer a wide range of services, including rapid prototyping. Our team of experienced engineers and machinists are dedicated to delivering high-quality, precision parts and components.

Rapid Prototyping

At CNC Rapid, we understand the importance of speed in the prototyping process. That’s why we offer rapid prototyping services to help you get your product to market as quickly as possible.

Small-Batch Production

In addition to prototyping, we also offer small-batch production services. This allows you to produce a small quantity of your product for testing and validation before moving on to full-scale production.

High-Volume Manufacturing

Once your product has been tested and validated, we can help you scale up to high-volume manufacturing. Our state-of-the-art facilities and experienced team are capable of handling large-scale production runs, ensuring that you can meet your market demand.

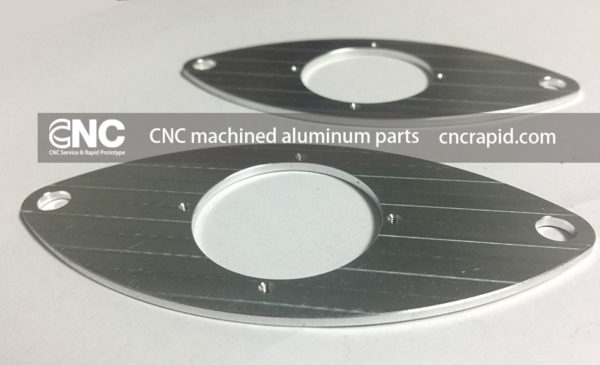

CNC Machined Aluminum Parts

At CNC Rapid, we specialize in the production of CNC machined aluminum parts. Our advanced CNC machines and skilled technicians ensure the highest level of precision and quality for all your aluminum parts needs.

CNC Turned Components

Our services also include the production of CNC turned components. We utilize advanced CNC turning machines to create complex parts with exceptional accuracy and consistency.

Aluminum Machining Suppliers

As one of the leading aluminum machining suppliers in China, we are committed to providing our clients with the highest quality aluminum parts. Our extensive experience and advanced machinery allow us to meet the most demanding specifications and tolerances.

China Rapid Prototyping

Our rapid prototyping services are designed to help you bring your product to market as quickly as possible. We use the latest CNC technology to create accurate and functional prototypes in a short timeframe.

CNC Machining Aluminum Parts

We are experts in CNC machining aluminum parts. Our advanced CNC machines and experienced technicians ensure that we can produce high-quality, precision parts to meet your specific requirements.

Get Started Today

Ready to get started with CNC machining prototyping? Contact CNC Rapid today for a quote. We’re here to help you bring your product to life.

We invite you to take advantage of our Metal & Plastic parts machining service, ideal for both prototypes and production needs. To receive a personalized quote, simply visit our website to get quote or reach out directly to our team at [email protected] with details of your project.

For the most accurate and speedy quote, kindly include the following in your communication:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your interest and look forward to serving your machining needs. Thank you for your time!