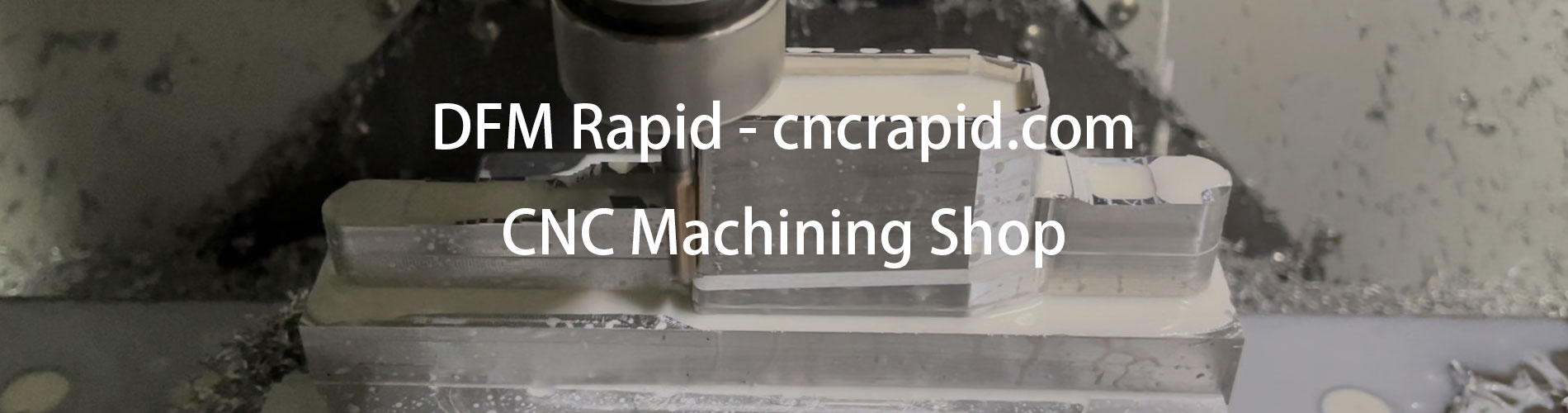

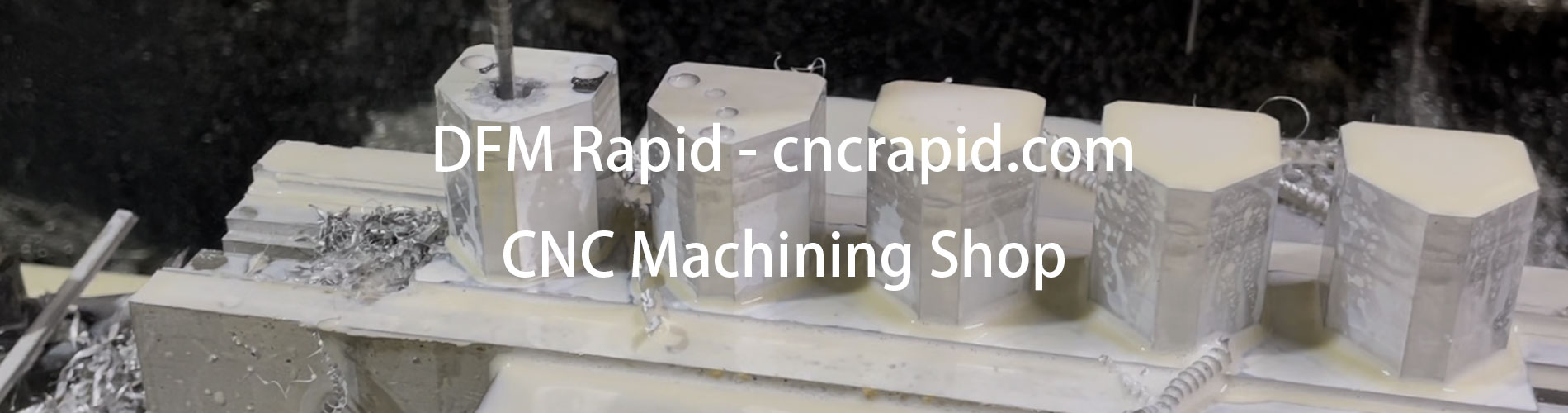

Rapid prototyping CNC machining is a process of quickly producing prototypes or small batches of parts using CNC machines. CNC machines use computer-controlled cutting tools to remove material from a solid block of material, producing highly accurate and complex parts with tight tolerances.

The benefits of rapid prototyping CNC machining are numerous. It allows engineers and designers to quickly test and iterate on their designs before moving into mass production, reducing time-to-market and development costs. Rapid prototyping CNC machining can be used to produce parts from a variety of materials, including metals, plastics, and composites, and it is a highly precise and repeatable process.

Rapid prototyping CNC machining is of critical importance in the manufacturing industry, enabling companies to bring new products to market faster and more efficiently. It has revolutionized the way that products are designed and developed, allowing companies to be more agile and responsive to changing market demands.

Materials used in Rapid Prototyping CNC Machining

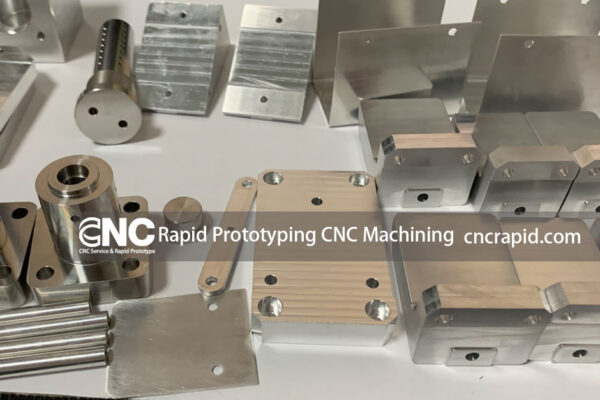

Rapid prototyping CNC machining can be used with a wide range of materials, including metals, plastics, ceramics, composites, and more. Each material has its unique properties that affect the CNC machining process and the resulting part’s quality.

- Metals such as aluminum, steel, and titanium are commonly used in rapid prototyping CNC machining due to their strength, durability, and ability to withstand high temperatures. These materials are often used in the aerospace, automotive, and medical device industries.

- Plastics such as ABS, polycarbonate, and nylon are also commonly used in rapid prototyping CNC machining due to their ease of machining, low cost, and ability to be easily molded into complex shapes. These materials are often used in the consumer electronics, medical device, and automotive industries.

- Ceramics such as zirconia and alumina are used in rapid prototyping CNC machining due to their high strength and wear resistance. These materials are often used in the medical device, dental, and aerospace industries.

- Composites such as carbon fiber and fiberglass are used in rapid prototyping CNC machining for their strength, stiffness, and light weight. These materials are often used in the aerospace, automotive, and sporting goods industries.

The material properties affect the CNC machining process in several ways. For example, metals require slower cutting speeds and higher tool temperatures than plastics, which are softer and more easily machined. Ceramics require special tooling and techniques to avoid cracking or chipping during machining. Composites require special attention to prevent delamination during machining.

The processes of Rapid prototyping CNC machining

- Milling is the most common process in rapid prototyping CNC machining, involving the removal of material from a workpiece using a rotating cutting tool. It is used to create complex shapes and features on parts, such as pockets, slots, and contours.

- Drilling is the process of creating holes in a workpiece using a rotating cutting tool. It is commonly used for creating holes for fasteners or fluid passages.

- Turning is the process of removing material from a workpiece using a rotating cutting tool while the workpiece rotates on a spindle. It is commonly used for creating cylindrical shapes and features such as grooves and threads. The benefits of turning include high accuracy and surface finish.

- Electrical discharge machining (EDM) is a process that uses an electrically charged wire or electrode to erode material from a workpiece. It is commonly used for creating complex shapes and features in hard or difficult-to-machine materials. The benefits of EDM include the ability to create complex shapes and features with high accuracy and surface finish.

What Can Rapid Prototyping CNC Machining Do?

- Product design: Rapid prototyping CNC machining allows designers to quickly and accurately create physical prototypes of their designs, enabling them to test and refine their designs before committing to expensive tooling and production runs. This helps to reduce design errors and shorten the product development cycle.

- Prototyping: Rapid prototyping CNC machining is commonly used to produce functional prototypes that can be used to test the form, fit, and function of a part or assembly. This enables designers to identify design flaws and make improvements before committing to production.

- Small-batch production: Rapid prototyping CNC machining is ideal for producing small batches of parts quickly and economically, without the need for expensive tooling or molds. This makes it an attractive option for manufacturers that need to produce small quantities of parts for niche markets.

- Mass production: Rapid prototyping CNC machining can also be used for mass production of parts, particularly for high-value, low-volume products. The ability to produce complex shapes and features with high accuracy and repeatability makes it an attractive option for industries such as aerospace, automotive, and medical devices.

Applications of Rapid Prototyping CNC Machining

- Automotive: Rapid prototyping CNC machining is used to produce complex automotive parts, such as transmission components, engine blocks, and suspension components.

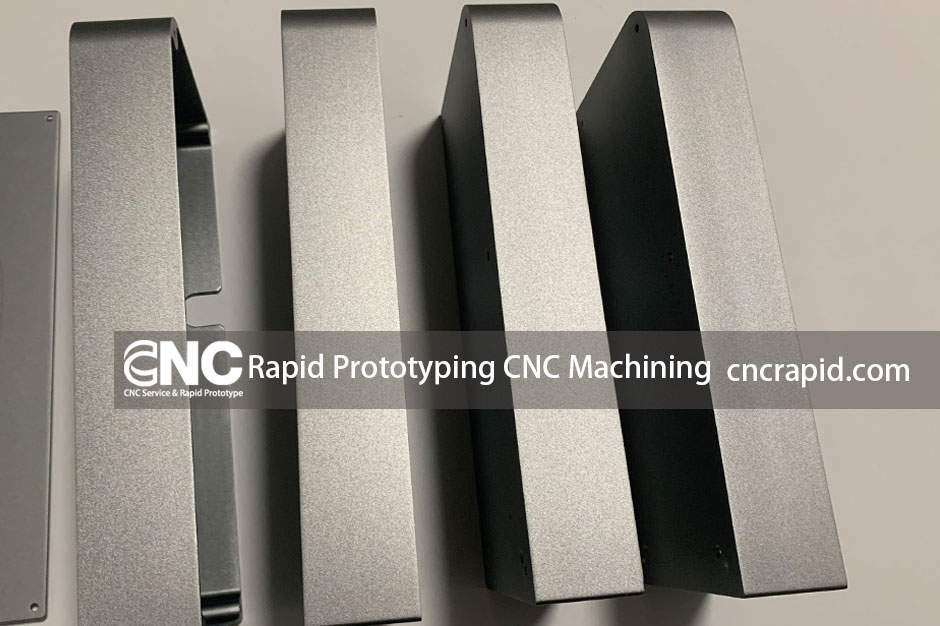

- Consumer electronics: Rapid prototyping CNC machining is used to produce small, intricate parts for consumer electronics, such as smartphone cases, camera housings, and laptop components.

- Industrial design: Rapid prototyping CNC machining is used in industrial design to create prototypes of products, such as furniture, lighting fixtures, and other consumer goods.

- Tooling: Rapid prototyping CNC machining is used to create tooling, such as injection molds and die casts, that can be used in the manufacturing of parts and components.

- Robotics: Rapid prototyping CNC machining is used to create custom parts for robots, such as arms, joints, and other components.

- Sports equipment: Rapid prototyping CNC machining is used to create high-performance sports equipment, such as bicycle frames, golf club heads, and tennis racket frames.

- Medical devices: Rapid prototyping CNC machining is used to produce custom medical devices, such as implants, prosthetics, and surgical instruments.

The versatility of rapid prototyping CNC machining is truly remarkable. From the wide range of materials that can be used to the various processes involved, this technology has revolutionized the manufacturing industry.

At DFM Rapid, we are proud to offer high-quality CNC machining services that leverage these advanced techniques. Our team of skilled engineers and machinists are committed to providing exceptional customer service and ensuring that our clients receive precisely the parts and prototypes they need.

If you have a project that could benefit from our CNC machining services, we would be delighted to hear from you. Please send us an email at [email protected] or visit our website to learn more about how we can help you bring your ideas to reality. Thank you for reading!

Contact us

If you need Metal & Plastic CNC Machining Parts for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!