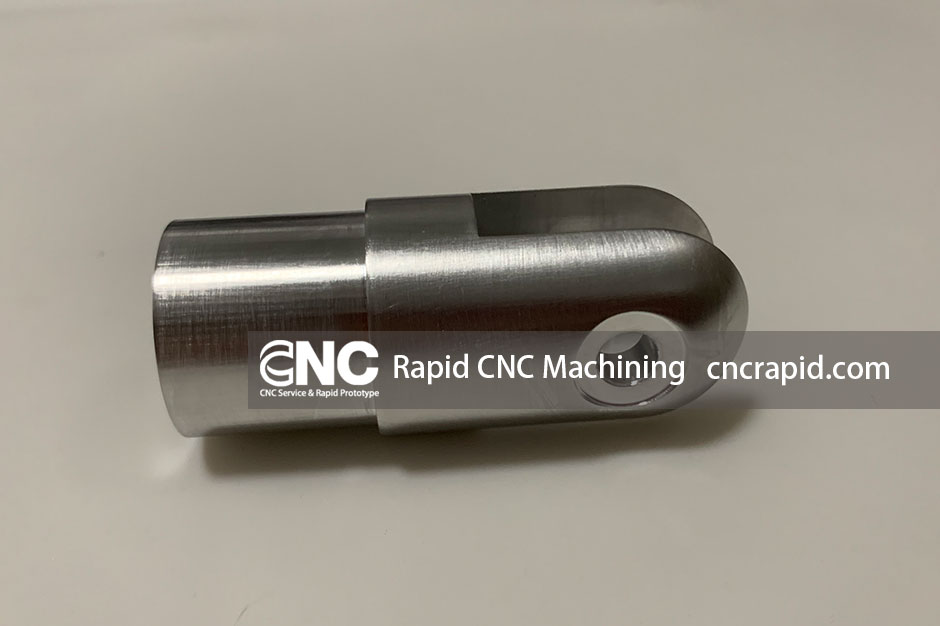

Rapid CNC machining is a cutting-edge technology that has revolutionized the manufacturing industry in recent years. It is a process that utilizes CNC machines to rapidly produce high-quality parts with speed and precision. By using advanced software and techniques, rapid CNC machining can greatly reduce the time and cost required for the manufacturing of parts and products.

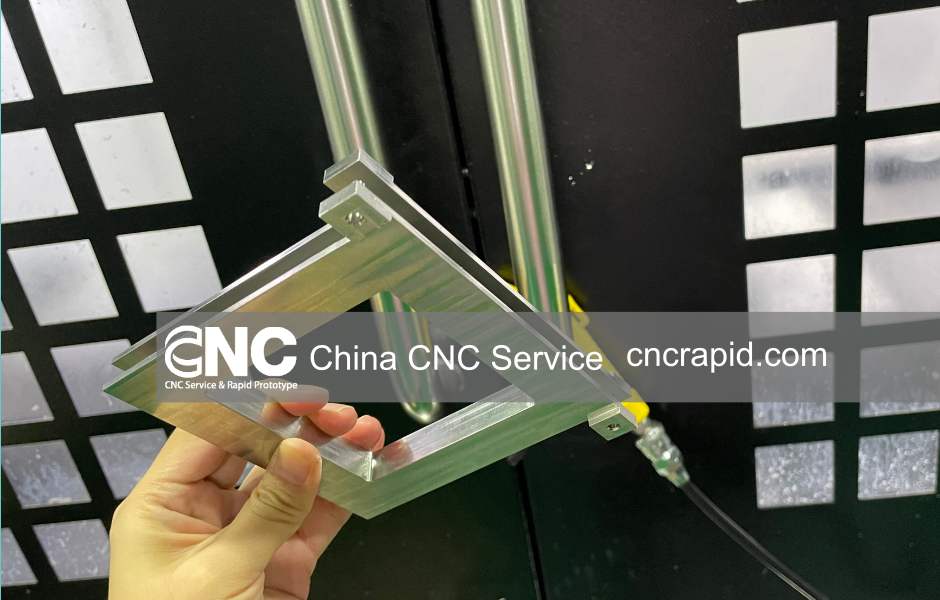

|

|

The benefits of rapid CNC machining are numerous. First and foremost, it allows for the quick and efficient production of parts with high levels of accuracy and precision. This means that manufacturers can get their products to market faster and more affordably, while maintaining a high level of quality.

And rapid CNC machining offers greater design flexibility than traditional manufacturing processes. It can produce parts with intricate shapes and geometries that would be difficult or impossible to produce with other methods. This allows for greater innovation and creativity in product design.

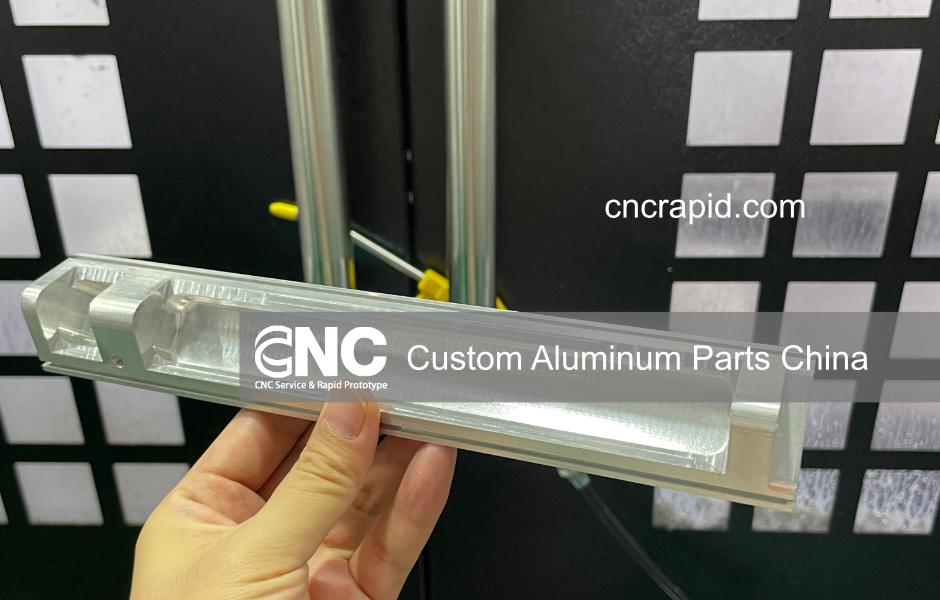

|

|

So rapid CNC machining is an innovative and efficient manufacturing technology that offers numerous benefits to manufacturers across a wide range of industries. By using this technology, manufacturers can reduce production time and costs, increase design flexibility, and deliver high-quality products to their customers faster and more affordably.

How Rapid CNC Machining Can Save You Time and Money?

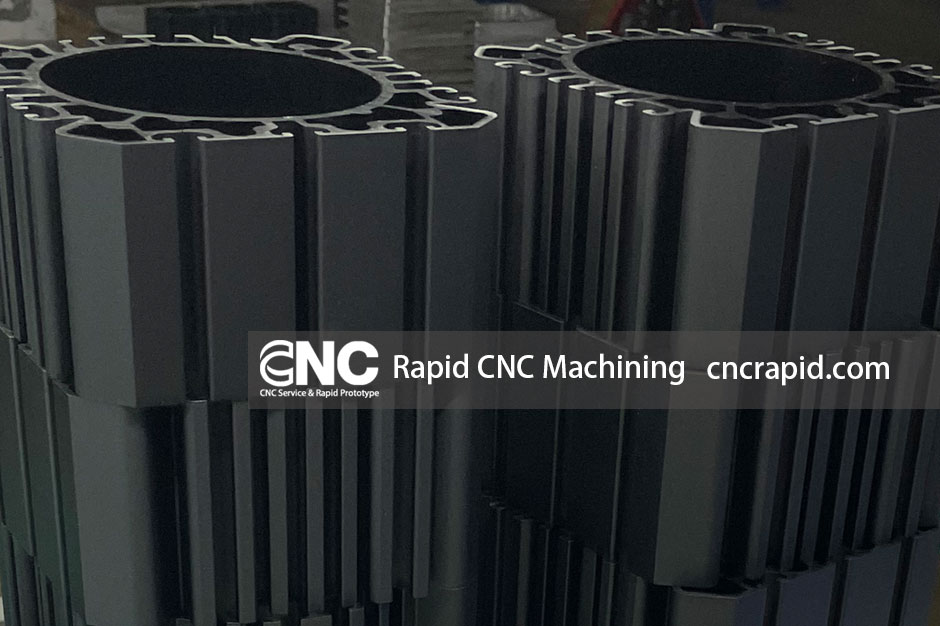

- Faster production times: With rapid CNC machining, parts can be produced at a much faster rate than traditional manufacturing methods. This is because the technology uses automated processes to quickly and accurately produce parts with minimal human intervention. This increased production speed can help manufacturers meet tight deadlines and reduce lead times, ultimately resulting in cost savings.

- Reduced labor costs: Traditional manufacturing methods often require significant amounts of manual labor, which can be costly and time-consuming. Rapid CNC machining, on the other hand, relies on automated processes that require less human intervention. This means that labor costs can be greatly reduced, resulting in significant savings for manufacturers.

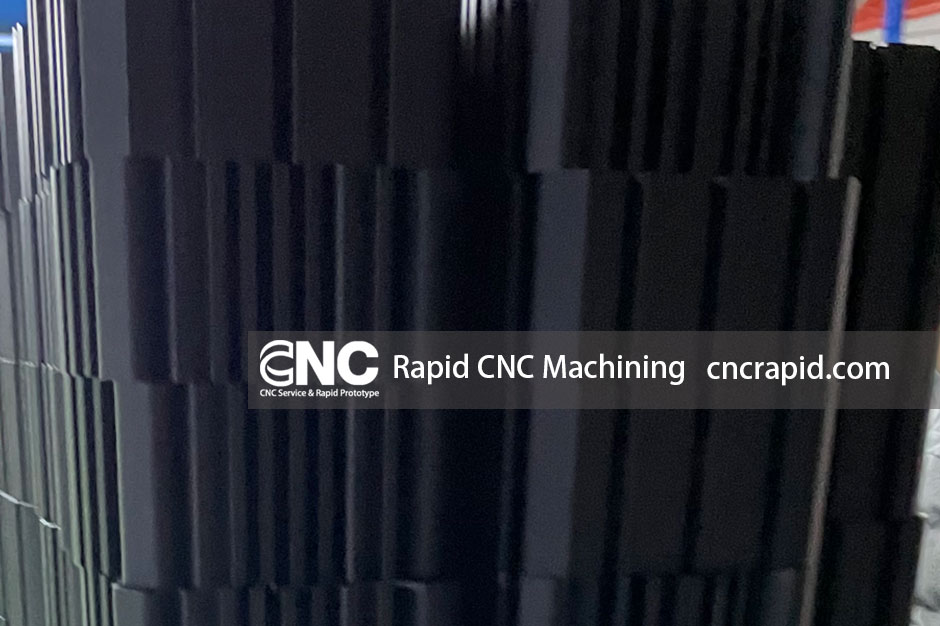

- Lower material waste: Rapid CNC machining uses advanced software and technology to optimize part design and production processes, which can greatly reduce the amount of material waste produced during manufacturing. This is because the technology allows for more precise and efficient use of materials, resulting in less scrap and lower material costs.

- Improved quality control: Rapid CNC machining offers greater accuracy and precision than traditional manufacturing methods, which can help to improve quality control. By reducing the number of defects and errors in the production process, manufacturers can avoid costly rework and production delays, saving both time and money.

So rapid CNC machining is a highly efficient and cost-effective manufacturing technology that offers a wide range of benefits. By reducing production times, labor costs, and material waste, and improving quality control, this technology can help manufacturers save time and money in the production process.

|

|

Why Choose Rapid CNC machining?

- Automated processes: Rapid CNC machining uses automated processes to produce parts, which reduces the need for manual labor and speeds up the production process. CNC machines can operate around the clock without breaks, which means they can produce parts much faster than manual labor alone.

- Faster programming: Rapid CNC machining software has become more advanced and user-friendly, allowing operators to create part programs much faster than in the past. This means that production can begin much sooner and with greater accuracy, reducing the time required for programming and setup.

- High-speed cutting: Rapid CNC machines use high-speed cutting tools that can remove material quickly and efficiently. This means that parts can be produced at a faster rate while maintaining high levels of accuracy and precision.

- Reduced material waste: The advanced software used in rapid CNC machining allows for optimized part design and production processes, which reduces the amount of material waste produced during manufacturing. This means that less material is wasted, and less time is spent managing and disposing of waste.

- Real-time monitoring: Many modern CNC machines have real-time monitoring capabilities that allow operators to monitor the production process and make adjustments in real-time. This means that errors can be identified and corrected quickly, resulting in less downtime and more efficient production.

The increased speed and efficiency of rapid CNC machining is a major advantage in the manufacturing industry. With the ability to produce parts quickly and accurately, manufacturers can meet tight deadlines and reduce lead times, ultimately resulting in increased productivity and cost savings.

Why Choose DFM Rapid?

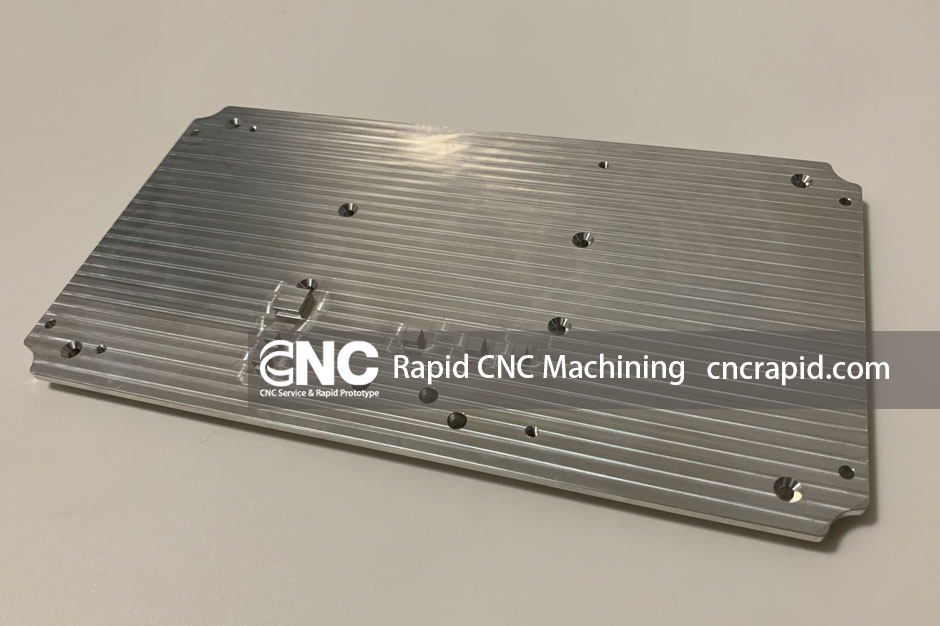

At DFM Rapid, we are dedicated to providing our customers with the most efficient and cost-effective rapid CNC machining services available. With our advanced equipment and experienced team of engineers and technicians, we have the capability to produce high-quality parts and components at lightning-fast speeds, without sacrificing accuracy or precision.

Our rapid CNC machining services are ideal for businesses in a variety of industries, from automotive and aerospace to medical devices and consumer products. We use the latest technology and software to design and manufacture parts with the utmost speed and accuracy, ensuring that our customers can bring their products to market quickly and efficiently.

|

|

Whether you need a prototype or a large-scale production run, we are equipped to handle your project with speed and expertise. Our team will work closely with you to understand your specific needs and requirements, and we will deliver results that meet or exceed your expectations.

At DFM Rapid, we are committed to providing the highest quality rapid CNC machining services to our customers, all while maintaining the fastest turnaround times and the most competitive pricing in the industry. Contact us today to learn more about how we can help you bring your products to market with speed and precision.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!