Project Description

Designing mechanical components with intricate features often challenges standard manufacturing capabilities. Among these challenges, CNC machining internal splines is considered one of the most difficult tasks for many machine shops.

Because CNC milling tools are cylindrical, creating the sharp internal corners required for splines and gears is physically impossible with standard end mills.

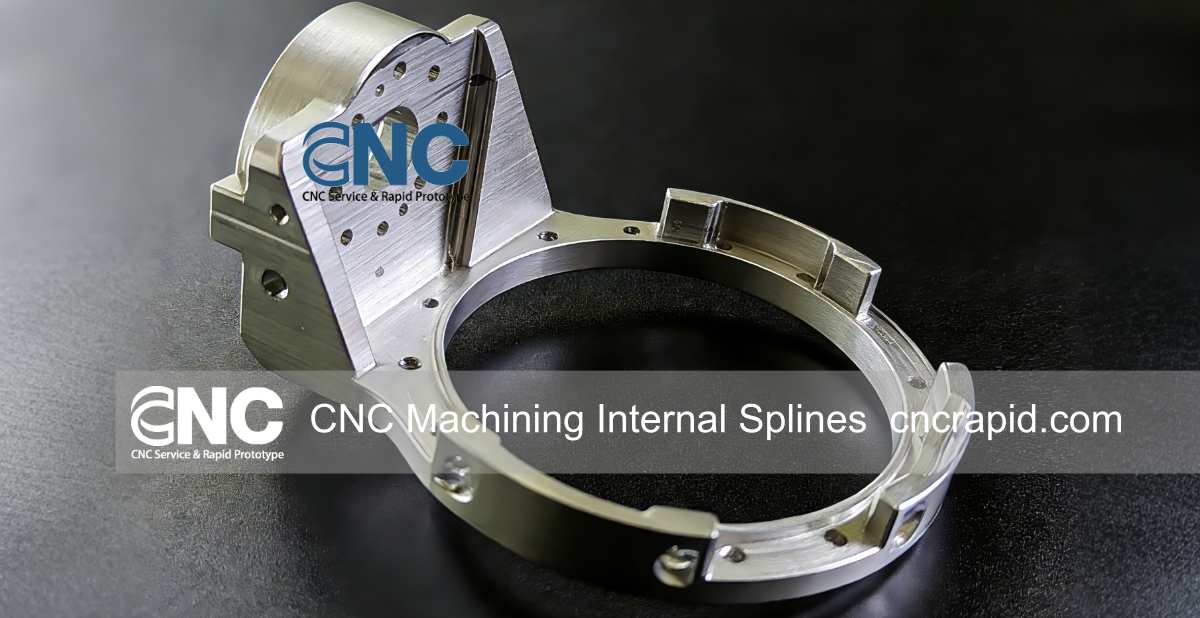

At CNC Rapid, we specialize in solving these “impossible” challenges. In this case study, we demonstrate our process for CNC machining internal splines within a complex custom aluminum housing for a robotics client.

The Challenge: Internal Splines & Complex Geometries

The part shown above is a critical transmission component. It presented two major manufacturing hurdles:

- Internal Splines (Blind Holes): The internal gear teeth required tight tolerances for proper mating with the drive shaft. Since standard CNC milling leaves a radius in the corners, we needed a specialized strategy to clear the material and create the gear profile.

- Thin-Wall Deformation: As seen in the housing structure, the walls are complex and thin. Removing large amounts of material from an aluminum block can release internal stress, causing the part to warp.

Our Solution: How We Machined It

To produce this complex aluminum part, we combined multi-axis CNC milling with specialized finishing processes.

1. 5-Axis CNC Milling for the Main Shape We utilized our 5-axis machining centers to carve the complex outer geometry. This allowed us to machine the part from multiple angles in a single setup, ensuring that all mounting holes and features were perfectly concentric relative to the center bore.

2. Handling the Internal Splines (The Key Technique) For the internal splines, standard milling wasn’t enough. Depending on the specific radius requirements and depth, we typically employ one of two advanced methods:

- Wire EDM (Electrical Discharge Machining): For splines requiring sharp corners and extreme precision (+/- 0.005mm), we use Wire EDM to cut the profile. This is a non-contact process that prevents any stress on the part.

- Broaching/Shaping: For higher volume orders, we use custom broaching tools to cut the spline profile efficiently.

3. Stress Relief for Thin Walls To prevent the housing from deforming, we used a “Roughing -> Stress Relief -> Finishing” workflow. By allowing the aluminum to stabilize before the final cut, we achieved a flat, dimensionally accurate part.

Why Choose Aluminum 6061 or 7075?

For this project, the client selected Aluminum 7075-T6.

- Strength: It offers strength comparable to many steels.

- Weight: It keeps the robotic arm assembly lightweight, reducing motor load.

- Machinability: Despite its hardness, it machines cleanly, allowing us to achieve the incredible surface finish seen in the photos—without the need for manual polishing.

Our Advantage: In-House CNC Gear Machining

Beyond our 5-axis milling and EDM capabilities, CNC Rapid is also equipped with specialized CNC Gear Machines (Gear Shapers and Hobbers).

While Wire EDM is excellent for prototyping complex splines, our dedicated gear cutting equipment offers a significant advantage for production runs. This capability allows us to:

- Reduce Costs: Gear shaping is significantly faster than EDM for manufacturing internal splines and gears in higher volumes.

- Ensure Consistency: Dedicated gear machinery guarantees uniform tooth profiles across thousands of parts.

- Handle Variety: From internal involute splines to external spur gears, we have the right machine for the job.

This means we don’t just force one method on every project; we choose the most efficient process—whether it’s Milling, EDM, or CNC Gear Cutting—to save you money.

Summary: Expert Capabilities for Difficult Parts

Many machine shops turn away quotes that include internal splines or complex, deformation-prone geometries. At CNC Rapid, we welcome the challenge.

Our capabilities include:

- CNC Milling & Turning

- Wire EDM & Sinking EDM (for internal corners/gears)

- Surface Finishing (Anodizing, Plating, Polishing)

Need a Quote for Complex CNC Parts?

Do you have a design with internal gears, splines, or tight tolerances? Don’t compromise on your design.

Get a Free Quote Today. Upload your STEP/IGES files, and our engineers will provide a free DFM (Design for Manufacturing) review and a competitive quote within 24 hours.

Contact Us

For more information or to discuss your CNC milling requirements, please contact us at [email protected]. Let CNC Rapid be your partner in precision machining.