The robotics and automation industry is a rapidly growing and dynamic field that is having a significant impact on many aspects of modern life.

This industry is about the design, manufacture, and use of robots and automated systems for a variety of applications. These systems can be used in a wide range of industries, including manufacturing, healthcare, transportation, and others. The robotics and automation industry encompasses the development of robotic hardware, software, and control systems, as well as the integration of these components into complete systems and applications.

To keep up with these developments, it’s important to have access to high-quality, precision components that can meet the demands of these complex and demanding systems. That’s where CNC machining comes in.

CNC machining is a process that uses computer-controlled tools to manufacture high-precision components and parts. By using this process, engineers can produce parts that meet tight tolerances and consistent dimensional accuracy, making them ideal for use in robotics and automation systems.

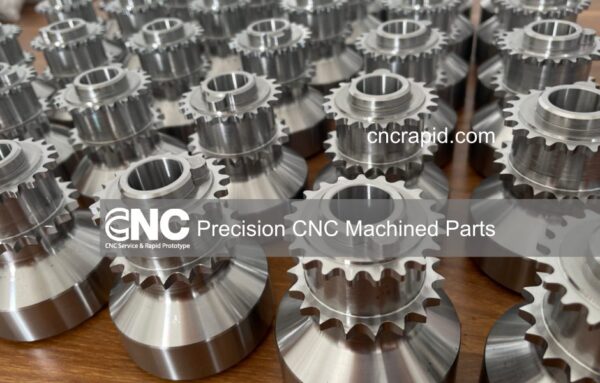

CNC machining can produce a wide range of components and parts for the robotics and automation industry, such as:

- Actuators: CNC machined actuators are critical components in many robotic and automation systems. These parts help to translate control signals into physical motion and provide the necessary force and motion to perform various tasks.

- Gearboxes: Gearboxes are essential components in many robots and automation systems, and CNC machining can provide precise and consistent gear teeth profiles and spacing, resulting in smooth and reliable operation.

- Drive shafts: Drive shafts are used to transmit rotational power from a motor to other components in a robot or automation system. CNC machining can produce highly accurate drive shafts with tight tolerances, helping to ensure reliable operation.

- Robotics arms: The arms of robots can be complex components that require precise and consistent dimensional accuracy. CNC machining can produce these components with the necessary precision and accuracy, helping to ensure that robots can perform their tasks effectively.

- Encoders and linear scales: These components are used to measure position, distance, and velocity in many automation and robotics systems. CNC machining can provide the precise and consistent parts needed to accurately measure these parameters.

- Brackets and mounting plates: Brackets and mounting plates are used to securely mount components in robotics and automation systems. CNC machining can produce these components with the necessary precision and accuracy to ensure stable and secure mounting.

- Custom components: CNC machining can also produce custom components for robotics and automation systems, allowing businesses to create unique solutions for their specific needs and requirements.

The benefits of using CNC machined parts in robotics and automation systems:

- Precision and dimensional accuracy: CNC machining allows for the production of parts with tight tolerances and consistent dimensional accuracy, which is essential for ensuring the reliable and accurate operation of robotics and automation systems.

- Material selection: With CNC machining, engineers have the flexibility to choose from a wide range of materials, including metals, plastics, and composites. This allows them to select the right material for their application, taking into account factors such as strength, stiffness, thermal stability, and corrosion resistance.

- Surface finish: CNC machining also provides the ability to produce parts with a wide range of surface finishes, from rough to mirror-smooth. This allows engineers to specify the surface finish that is best suited to their application, whether it’s to reduce friction, improve wear resistance, or enhance aesthetics.

- Lead time: CNC machining is a highly efficient process that can be completed quickly and with a high degree of automation. This makes it possible to manufacture components and parts in a timely manner, meeting the fast-paced demands of the robotics and automation industry.

- Quality control: CNC machining is also a highly controlled and automated process, making it possible to maintain consistent quality across all parts. This ensures that each part meets the required specifications and performs as expected in a robotics and automation system.

By leveraging the benefits of CNC machining, engineers can produce high-quality, precision components and parts that meet the demanding requirements of their robotics and automation systems. Whether it’s for a new application or a critical repair, CNC machining is the solution for optimized performance and reliability.

CNC machined components can also help to reduce costs and improve the overall performance and efficiency of robotics and automation systems. By using precise and consistent components, engineers can reduce the need for costly manual adjustments and rework, saving time and resources. Moreover, the use of high-quality components can help to extend the lifespan of a robotics and automation system, reducing maintenance costs and downtime.

CNC machined components play a crucial role in the development and optimization of robotics and automation systems. By leveraging the precision and accuracy of CNC machining, engineers can produce components that meet their exact specifications and deliver reliable and efficient performance. Whether you’re looking to develop a new system or upgrade an existing one, CNC machined components are an essential part of the solution.

Why choose DFM Rapid as your CNC machining partner?

At DFM Rapid, we understand the critical importance of precision and quality in the robotics and automation industry. That’s why we specialize in providing top-notch CNC machining services, using the latest technology and best practices to deliver high-quality components and parts that meet your exact specifications.

Our team of experienced engineers and machinists have extensive experience working with a variety of materials and technologies, ensuring that we can deliver the perfect solution for your needs. Whether you’re looking to develop a new system or upgrade an existing one, we have the expertise and resources to help you achieve your goals.

So, if you’re looking for a reliable and efficient partner for your CNC machining needs, look no further than DFM Rapid. Contact us today to learn more about how we can help you optimize your robotics and automation systems.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!