CNC prototyping is the process of using computer-controlled machine tools to create intricate and precise components from various materials. It’s a leap from traditional manufacturing, offering unparalleled precision and flexibility.

Materials in CNC Machining and Their Properties

CNC machines are versatile, capable of working with a diverse array of materials, each offering unique properties:

- Aluminum: Lightweight, strong, and corrosion-resistant, ideal for aerospace and automotive parts.

- Stainless Steel: Known for its strength and corrosion resistance, perfect for medical and food industry applications.

- Brass: Easy to machine, offering a balance of strength, ductility, and corrosion resistance, commonly used in electrical components and decorative items.

- Copper: Excellent electrical conductivity, often used in electrical components, and known for its thermal conductivity and ductility.

- Steel: Highly durable and strong, used in a variety of applications from construction to automotive.

- Acrylic: Known for its clarity and resistance to breakage, used in lenses and display cases.

- Nylon: Durable and wear-resistant, suitable for gears and bearings.

- ABS: A common thermoplastic with good mechanical properties, used in consumer goods and automotive components.

- POM: Known for its high stiffness, low friction, and excellent dimensional stability, used in precision parts requiring high stiffness.

Why Choose CNC for Prototyping?

- Precision and Consistency: CNC machines operate with high accuracy, ensuring each part is replicated exactly, which is crucial for prototyping.

- Versatility in Materials and Designs: From metals to plastics, CNC machines can handle a wide range of materials and complex designs that other methods cannot.

- Speed and Efficiency: CNC prototyping significantly reduces production time, allowing for rapid iteration and development.

- Cost-Effective for Low to Medium Volume: For small to medium-sized runs, CNC prototyping is more cost-effective than traditional manufacturing, reducing waste and the need for expensive tooling.

Minimizing Costs in CNC Prototyping

- Optimize Design for Manufacturing: Simplify your design to reduce machining time and material usage. Avoid unnecessary complexities that require additional machining steps.

- Material Selection: Choose cost-effective materials that still meet the functional requirements of the prototype.

- Batch Production: If feasible, produce multiple parts in a single batch to maximize machine usage and reduce setup times.

- Leverage Expertise: Collaborate with experienced CNC technicians who can offer insights into efficient design modifications and machining processes.

- Utilize Advanced Software: Employ CAD/CAM software to simulate and plan the manufacturing process, identifying potential issues before production begins.

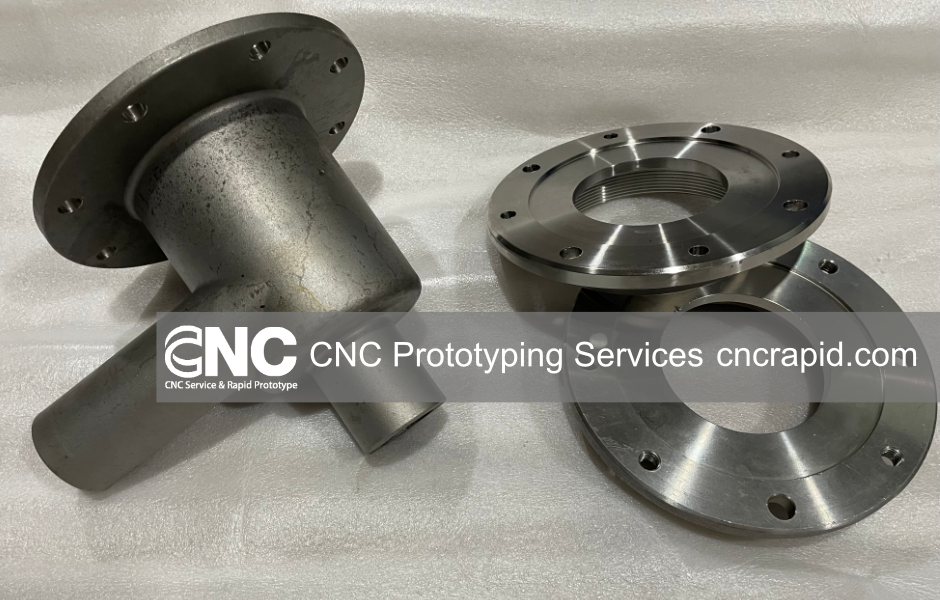

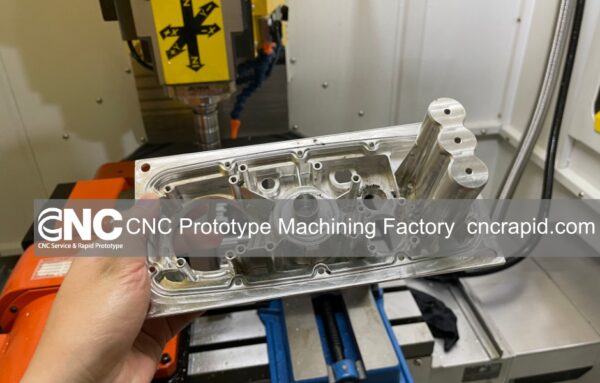

Our Expertise in CNC Prototyping

At CNC Rapid, we embody the spirit of Chinese innovation in CNC prototyping. Our expertise lies in delivering high-quality, custom CNC solutions. Our team, equipped with advanced machinery and years of experience, ensures that each prototype exceeds expectations.

Get in Touch

Ready to bring your ideas to life with precision and excellence? Contact us at [email protected] or visit Get a Quote to get started on your next CNC prototype project. Let’s build the future, one prototype at a time.