Project Description

In the world of motorsports, electric vehicles (EVs), and high-end robotics, standard cast wheels often fail to meet specific performance requirements. Engineers look for a solution that offers a perfect balance of lightweight design, structural strength, and custom aesthetics.

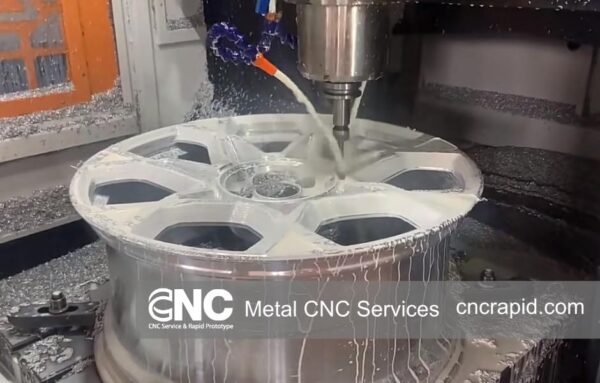

At CNC Rapid, we specialize in manufacturing Custom Billet Aluminum Wheels. Unlike mass-produced cast rims, our wheels are CNC machined from a solid block of aerospace-grade aluminum, offering superior density and durability.

Here is a look at a recent project featuring a stunning Blue Anodized finish.

Why Choose Billet Aluminum over Casting?

The wheel shown above was machined from a solid billet of Aluminum 6061-T6. Choosing CNC machining over casting offers three distinct advantages for prototyping and low-volume production:

- Strength-to-Weight Ratio: Billet aluminum has a uniform grain structure, making it significantly stronger than cast aluminum. This allows us to machine thinner spokes (as seen in the photo) to reduce unsprung weight without risking structural failure.

- Design Flexibility: You are not limited by molds. Whether you need a unique offset, a custom bolt pattern, or an intricate spoke design, CNC machining can create geometries that are impossible or too expensive to mold.

- Speed: No need to wait weeks for mold tooling. We can take your CAD file and start machining immediately.

The Manufacturing Process: Turning & Milling

Creating a Custom Billet Aluminum Wheel requires a hybrid machining strategy:

CNC Turning (Lathe): First, we use our large-diameter CNC lathes to turn the outer profile, the rim bead seat, and the center bore. This ensures the wheel is perfectly round and balanced.

- 5-Axis CNC Milling: Next, we use 5-axis milling to carve out the complex spoke patterns and bolt holes.

- Note on the photo: Notice the smooth transitions between the spokes and the rim. This requires simultaneous 5-axis movement to avoid tool marks and stress concentrations.

Surface Finish: Bead Blasting & Anodizing

A raw machined wheel is functional, but a premium wheel needs a premium finish. The deep blue color you see is not paint—it is Type II Anodizing.

To achieve this specific look, we followed a two-step process:

- Bead Blasting: Before anodizing, we bead-blasted the part to remove fine tool marks. This creates a uniform, matte texture (satin finish) that diffuses light beautifully.

- Blue Anodizing: The part is submerged in an electrolytic bath to build a protective oxide layer. The blue dye is sealed into the metal pores. Benefit: This finish is harder than the aluminum itself, providing excellent resistance to brake dust, road debris, and corrosion.

Applications for Custom CNC Wheels

Our CNC Wheel Manufacturing service is ideal for:

- Formula Student (FSAE) & Go-Karts: Custom hubs and lightweight rims.

- Robotics & AGVs: Heavy-duty wheels for automated delivery vehicles.

- Custom Motorcycles & E-Bikes: One-off designs for show bikes.

- Prototype Vehicles: Testing new designs before committing to mass production casting.

Start Your Custom Wheel Project

Do you have a design for a Custom Billet Aluminum Wheel? Whether it’s a 10-inch wheel for a robot or a 18-inch wheel for a race car, CNC Rapid has the multi-axis equipment to handle it.

Get a Free Quote. We provide DFM feedback on weight reduction and finish options to help you build the perfect wheel.

Contact Us

For more information or to discuss your CNC milling requirements, please contact us at [email protected]. Let CNC Rapid be your partner in precision machining.