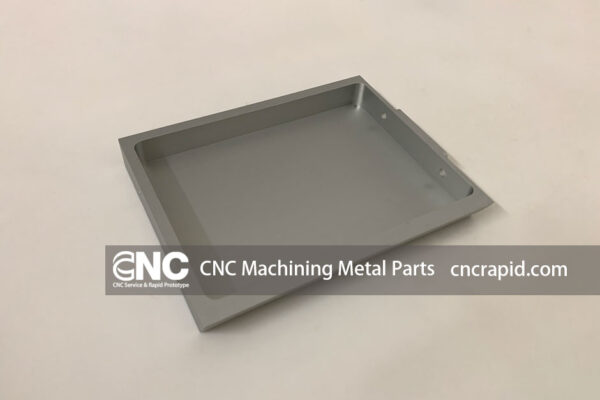

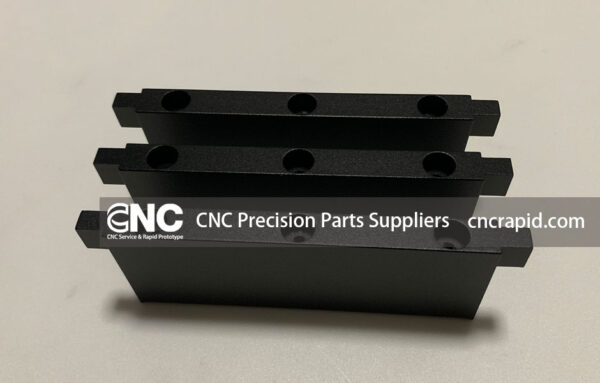

CNC Machining Services Factory. CNC Machining is a subtractive manufacturing method that uses cutting tools to remove material from a block of raw material or a pre-existing part. Our capacity allows us to create CNC machined parts with unrivaled speed. At the same time, our experienced engineers ensure the highest standards with cutting edge software and equipment.

CNC Turning

Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production.

CNC Milling

CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. We use domestic and imported 3, 4 and 5-axis CNC machining centers.

We offer a variety of expertly applied finishing options to improve the mechanical and aesthetic properties of your CNC machine component, including painting, anodizing, powder coating and hand polishing.

CNC Machining Services Factory

At DFM Rapid, we provide high-quality prototyping, CNC Machining services to support your product and parts development needs. Our engineers work with you to make your product ideas a reality through our manufacturing technologies like CNC machining, Rapid prototyping and a range of finish services. If you are ready to start your project, please feel free to get a quote online

Advantages Of CNC Machining

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

- Quick removal of large amounts of metal material

- Highly accurate and repeatable

- Suitable for many different kinds of substrates

- Scalable volumes from one to 100,000

- Low investment in tooling and preparation costs

- Economical

- Fast turnaround

Get a quote

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!