Welcome to the world of precision and efficiency! As a leading provider of CNC Milling and Turning services, we specialize in creating intricate parts with utmost accuracy. Our services extend across a broad spectrum of applications, including rapid prototyping, precision CNC machining, and custom CNC manufacturing.

The Art of CNC Turning

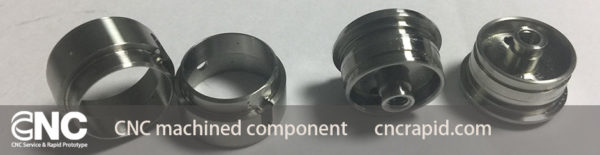

CNC lathes are our magic wand for high-speed turning of both plastics and metals. The turning process enables us to craft complex external and internal geometries, including all kinds of threads. Whether it’s round-shaped components like shafts, worms, or spheres, CNC turning is a more efficient method compared to CNC milling. Our turning capability is not just limited to prototypes but extends to mass production parts as well.

The Science of CNC Milling

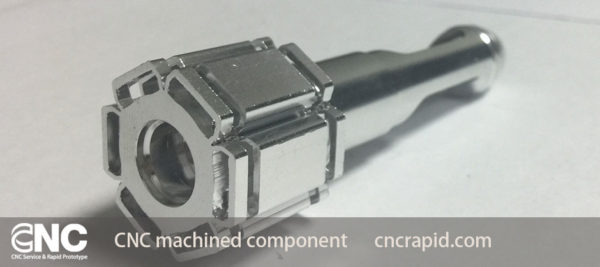

CNC milling, on the other hand, is our go-to process for creating complex 3D shapes. It can be used to apply a machined surface or features to parts made of both plastics and metals.

The unique advantage of multi-axis milling machines is that the spindle and the worktable move independently, while the part remains rigidly held in a vice on the worktable. This makes CNC milling versatile, accurate, and repeatable, perfect for creating a variety of part features and complex geometries. From holes, curves, slots, angled shapes, to channels, milling is also ideal for making tooling for pressure die casting and plastic injection molding.

Why CNC Machining?

CNC Machining, also known as computer numerical control machining, is a digital manufacturing technology known for its accuracy. It’s a fast, precise, and universal machining method, suitable for any quantity of product orders. The best part? There’s no need to make a mold, making it a cost-effective solution.

Materials We Work With

We can work with a wide range of metal materials such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy, and more. We also handle various plastics like acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

Our Capacity

Our maximum part size is 2000 x 600 x 600 mm, or 78.7 x 23.6 x 23.6 in. The standard of tolerance we maintain ranges from +/-0.01mm to +/-0.15mm.

Your One-Stop Shop for Custom Machining and Manufacturing

At DFM Rapid, also known as CNC Rapid, we provide a professional one-stop service in product development and volume production, from rapid prototype to CNC machining production.

Get a quote

If you need Metal & Plastic parts machined for Rapid CNC Services prototypes or production, please feel free to get a quote online

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

We appreciate your time and look forward to working with you!