Project Description

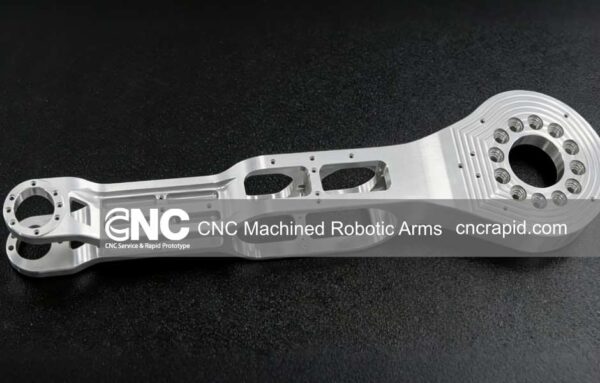

In the fast-paced world of robotics and automation, engineers are constantly fighting a battle against weight. A heavier robotic arm requires larger motors, consumes more power, and moves with less agility. The ultimate goal is to design a CNC Machined Robotic Arms that is incredibly light yet rigid enough to handle heavy payloads without deflecting.

At CNC Rapid, we specialize in turning massive blocks of aerospace-grade aluminum into highly optimized, skeletonized structural components. Let’s take a closer look at how we manufacture these advanced lightweight linkages.

The Art of Lightweighting: Deep Pockets and Thin Walls

Look at the extreme material removal on the custom aluminum linkage shown above. To achieve this level of weight reduction, the design utilizes a web of thin walls and deep pockets.

Machining a highly skeletonized part like this is a true test of a CNC shop’s capabilities:

- Stress Relief & Warping: Removing 70% to 80% of a solid aluminum block releases internal material stress, which naturally makes the part want to bend or twist. We use advanced roughing and finishing strategies to manage this stress, ensuring the final part remains perfectly straight.

- Chatter Prevention: Milling deep cavities between thin structural ribs can cause severe vibration (chatter). Our programmers utilize dynamic milling toolpaths and high-speed spindles to gently peel the material away, leaving the delicate ribs intact and structurally sound.

Precision Robotic Joints: Concentricity is Key

A robotic linkage is only as good as its joints. The large circular bores on both ends of this component are designed to house precision bearings, harmonic drives, or servo motors.

- Tight Tolerances: The bearing bores must be machined to extremely tight dimensional tolerances (often within micrometers) to prevent any slop or “backlash” in the robotic movement.

- Perfect Concentricity: The surrounding bolt hole circles must be perfectly concentric with the main center bore. We machine these critical mating features in a single CNC setup to guarantee absolute alignment, ensuring your robotic joints rotate smoothly.

Superior “As-Machined” Surface Finish

In high-performance applications, surface finish isn’t just about looking good—it’s about fatigue resistance. Rough tool marks can create micro-stress concentrations where cracks can form over time.

As you can see in the floor of the milled pockets, our As-Machined Finish is flawless. The smooth, sweeping tool paths eliminate sharp internal corners, maximizing the lifespan of the robotic arm under heavy dynamic loads. While we offer premium anodizing to protect the surface, the foundational machining quality speaks for itself.

Material Selection: Aerospace-Grade Aluminum

For robotic arms and suspension linkages, we highly recommend Aluminum 7075-T6 or 6061-T6. These billet materials offer an exceptional strength-to-weight ratio, rivaling some steels while weighing only a fraction as much.

Ready to Optimize Your Robotic Designs?

Don’t let manufacturing limitations hold back your robotic engineering. If you are designing a custom exoskeleton, an industrial automation arm, or a lightweight drone frame, CNC Rapid has the multi-axis machining technology to bring it to life.

Upload your 3D CAD files (STEP/IGES) today. Our engineering team will review your lightweight designs and provide a fast, competitive manufacturing quote.