CNC milling is a subtractive manufacturing process that uses CNC machine tools to create precise shapes and features in various materials. Components made through CNC milling are used in a wide range of industries, including aerospace, automotive, electronics, and medical.

The common CNC milling components

- Enclosures and housings: This includes electronic device enclosures, custom enclosures, and protective housings for various applications.

- Automotive parts: CNC milling is used to create various automotive components, such as engine parts, suspension components, and custom fittings.

- Aerospace components: Precision parts for aerospace applications, such as turbine engine parts, landing gear components, and structural components, are produced using CNC milling.

- Gears: Custom gears for various applications, such as automotive transmissions, robotics, and industrial machinery, can be manufactured using CNC milling.

- Molds and dies: CNC milling can create molds and dies for various manufacturing processes, such as injection molding or die casting.

- Heat sinks: These are used to dissipate heat from electronic components and can be made using CNC milling to create complex designs with high surface area.

- Machine components: CNC milling is used to create custom parts for machinery, such as shafts, bearings, and couplings.

- Fixtures and jigs: These are used to hold parts in place during manufacturing processes, and CNC milling can create custom fixtures and jigs for specific applications.

- Prototypes: CNC milling is often used to create prototypes to test the functionality and design of a product before it’s mass-produced.

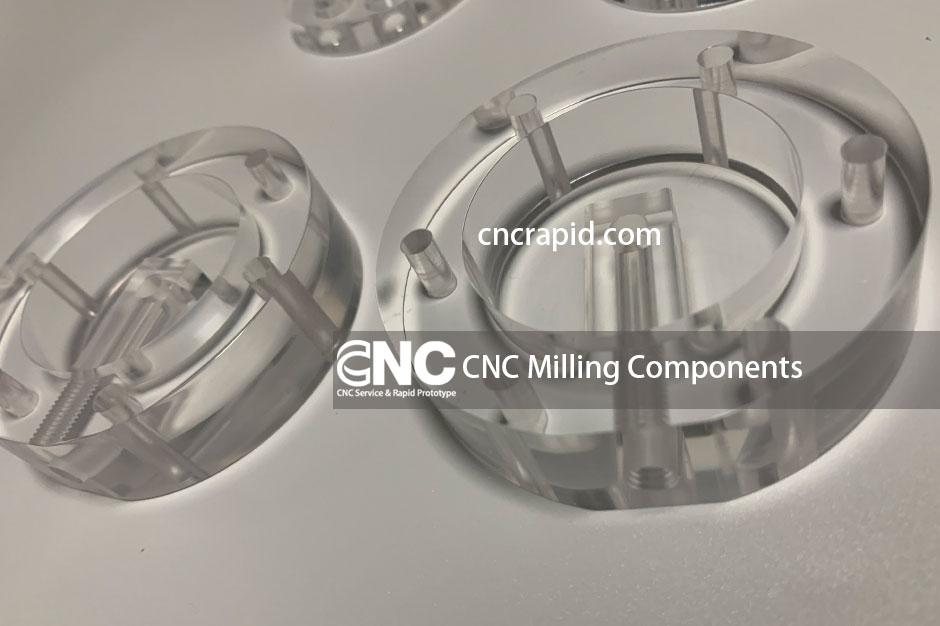

CNC milling components. Milling is the removal of metal with a rotary cutter or other rotating cutting tools. We use 3-axis milling processes to manufacture parts from more than 30 engineering-grade plastics and metals.

CNC milling components

Our facility is equipped with milling, drilling, tapping, thread milling and boring machinery to produce the specialized parts your application demands. We strive to for the utmost repeatability and reliability with each order.

Our experienced and versatile machinists are well equipped to tackle even the most complex precision milled metal components and custom milling parts. Years of CNC milling experience and high-end equipment combine to make producing high volumes of intricate parts possible.

CNC machining is a practical option for everything from prototype manufacturing to production runs. We are a one-stop shop for custom machining and manufacturing. We can produce custom prototypes and end-use production parts, please feel free to contact us.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

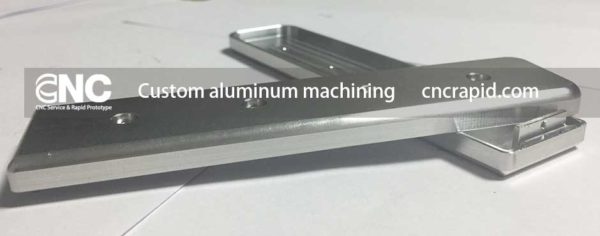

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Contact us

If you need Metal & Plastic parts machined for Rapid Prototyping Services or production, please feel free to get a quote online

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!