CNC prototyping is a crucial step in the product development process. Choosing the right material for your prototype is essential to ensuring that it meets the required specifications and functions as intended. With so many materials available, it can be challenging to determine which one is best for your prototype.

Purpose

- Strength: If your prototype needs to be able to withstand a high amount of stress or pressure, you may need to choose a material that is strong and durable, such as steel or titanium.

- Flexibility: If your prototype needs to be flexible or bendable, you may need to choose a material that is pliable or has a low modulus of elasticity, such as silicone or rubber.

- Heat resistance: If your prototype needs to be able to withstand high temperatures, you may need to choose a material that is heat-resistant, such as ceramic or thermoplastics.

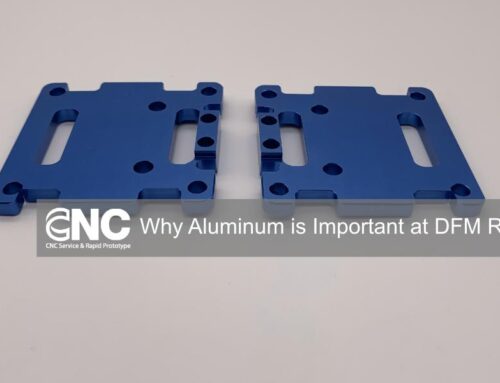

- Electrical conductivity: If your prototype needs to conduct electricity, you may need to choose a material that is a good electrical conductor, such as copper or aluminum.

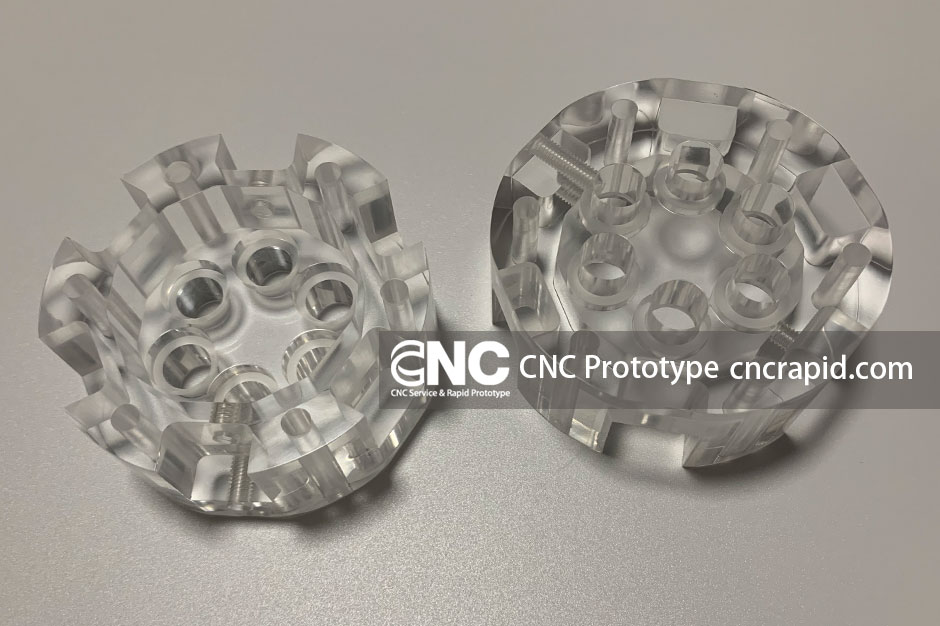

- Optical clarity: If your prototype needs to be transparent or have high optical clarity, you may need to choose a material that has low light absorption and high transmission, such as acrylic or polycarbonate.

Manufacturing Process

- Machinability: The machinability of a material refers to how easily it can be cut, drilled, or milled. Some materials may be more difficult to machine than others, which can affect the accuracy, speed, and cost of the manufacturing process. For example, metals such as aluminum or steel are generally easier to machine than materials like ceramics or composites.

- Cutting speed: The cutting speed of a material refers to the speed at which the CNC machine can cut through the material. Some materials may require slower cutting speeds to ensure accuracy and precision, while others may allow for faster cutting speeds. For example, plastics like acrylic can generally be cut at a faster speed than metals like stainless steel.

- Tooling: Different materials may require different types of cutting tools, such as end mills, drills, or routers. Choosing the right tooling can help ensure accuracy and quality during the manufacturing process. Some materials may require specialized tooling that can increase the cost of the process.

- Coolants: Depending on the material being machined, the CNC machine may require coolants to help dissipate heat and prevent damage to the tooling and material. Some materials may require specialized coolants that can increase the cost of the process.

Cost

- Material cost: The cost of materials can vary widely depending on the type, quantity, and availability. Some materials, such as metals and high-performance plastics, can be more expensive than others. It’s important to choose a material that fits within your budget but also meets the required specifications.

- Machining cost: The cost of machining can also be impacted by the material you choose. Some materials may require specialized tooling or cutting speeds, which can increase the cost of the manufacturing process.

- Production cost: The overall cost of production can be impacted by the material you choose. For example, if you choose a material that requires a longer machining time, this can increase the cost of production.

Choosing the right material for your CNC prototype is essential to ensuring that it meets your required specifications and functions as intended. By considering the purpose, manufacturing process, cost, compatibility, aesthetics, and sustainability of your material, you can make an informed decision that meets your needs. Test and iterate with your chosen material to ensure that it meets your requirements, and be prepared to try different materials if necessary.

About DFM Rapid

At our CNC shop, we specialize in providing high-quality CNC prototype services to meet your product development needs. With years of experience in the industry and advanced equipment, we are committed to providing our clients with precision prototypes that meet their specifications.

We understand that the prototype stage is a critical step in the product development process, which is why we offer a range of CNC machining services that can accommodate a variety of materials, shapes, and sizes. Our team of experienced machinists works closely with our clients to ensure that their prototypes are manufactured to their exact specifications and are delivered on time.

Our CNC prototype services are ideal for a range of industries, including aerospace, automotive, medical, and electronics. We have worked with clients from around the world, providing them with the highest quality prototypes that meet their unique requirements.

We take pride in our commitment to customer satisfaction and strive to exceed our clients’ expectations with every project we undertake. From the initial design concept to the final product, we are dedicated to providing our clients with the best possible service and support.

If you’re in need of precision CNC prototype services, look no further than our CNC shop. Contact us today to learn more about our services and how we can help you bring your product to life.

Contact us

If you need Metal & Plastic CNC Machining Parts for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!